Experimental study of weld position detection based on keyhole infrared image during high power fiber laser welding*

2015-10-31ChenYuquanGaoXiangdongXiaoZhenlinandChenXiaohui

Chen Yuquan,Gao Xiangdong,Xiao Zhenlin and Chen Xiaohui

陈余泉,高向东,萧振林,陈跷辉**

Experimental study of weld position detection based on keyhole infrared image during high power fiber laser welding*

Chen Yuquan,Gao Xiangdong,Xiao Zhenlin and Chen Xiaohui

陈余泉,高向东,萧振林,陈跷辉**

Keyhole is one of the important phenomena in high-power laser welding process.By studying the keyhole characteristic and detecting the seam offset during high-power fiber laser welding,an infrared sensitive high-speed camera arranged off-axis orientation of laser beam was applied to capture the dynamic thermal images of a molten pool.The 304 austenitic stainless steel plate butt joint welding experiment with laser power 10 kW was carried out.Through analyzing the keyhole infrared image,the weld position was calculated.Least squares method was used to determine the actual weld position.Image filtering technique was used to process the keyhole image,and the keyhole centroid coordinate were calculated.Also,least squares method was used to fit the keyhole centroid curve equation and establish a nonlinear continuous model which described the deviation between keyhole centroid and weld seam.The heat accumulation effect affected by the infrared radiation was analyzed to determine whether the laser beam focus spot deviated from the desired welding seam. Experimental results showed that the keyhole centroid has related to the seam offset,and can reflect the welding quality.

infrared image,keyhole centroid,high power fiber laser welding,seam offset

0 Introduction

In industrial welding circumstance,seam tracking is prerequisite to obtain good welding quality[1].Owing to the high-intensity power and rapid welding speed of highpower fiber laser welding,it is difficult to detect seam position accurately,especially when the seam is less than 0.1 mm.Nowadays more and more visual sensors have been applied in welding process[2-3].To detect weld seam whose width is very narrow,a promising approach is to identify the seam offset between laser beam focus spot and weld center from a molten pool image captured by a camera.But because of the strong arc light influence in highpower laser welding process,it is difficult to directly obtain a clearer weld image.This is not conducive to judge weld seem position and severely restricted the application and popularization of visual sensing method.Laser welding is a complicated thermodynamic and physic chemical process,which involves material melting,evaporating,plasma forming,keyhole occurrence,and so on.

The dynamic behavior of keyhole in laser welding could be studied by means of paraxial visual sensing technology[4].The side shape of keyhole was detected by means of X-ray transmission aided techniques.A coaxial visual system could be applied to capture the weld pool and keyhole images,and qualitatively the relationship between the keyhole width and the weld penetration were analyzed[5].If an electro-mechanical or purely mechanical system is used to drive the welding piece,nonlinear factors will also be inevitably introduced to the welding process and influence the system performance.Thus,the laser welding should be treated as a nonlinear process by many researchers[6-8].Also,the keyhole centroid was an-alyzed to determine whether the laser beam was focused on or deviated from the desired weld seam.Finally,least squares method was used to fit the keyhole centroid curve equation,and a nonlinear continuous deviation model of the keyhole centroid and weld seam was established.The heat accumulation effect affected by the infrared radiation was analyzed to determine whether the laser beam focused or deviated from the desired weld seam.In this paper,the keyhole features that related to the seam offset during high power fiber laser welding was analyzed.

1 Experiment

1.1Molten pool infrared radiation

Laser welding is often referred to as a high energy density or power beam technique.The fact that absorption of a laser beam increases with temperature has enabled the use of laser beam as a practical heat source for welding. For a fiber laser welding,the absorptivity of carbon steel varies from 4%at room temperature to more than 30%at melting temperature and reaches about 90%at vaporizing temperature[9].In the welding process,the interactions of high energy density laser beam with the weldment produce strong optical reaction,the heated and molten material radiates from the surface,mainly in the infrared(IR)spectral region.This radiation can be described by Planck’s law for black body radiation[10].

where Eλbis the spectral emissive power,λ is wavelength,k is the Boltzmann constant,h is the Planck constant,T is surface temperature and c is the speed of light.The maximum of Eλbis found at λmaxas described by the displacement law of Wien

For steel with a melting temperature around Tm= 1 800 K and a boiling point around Tv=2 800 K,the spectral peak of melt pool radiation varies between λmax= 1 000 nm and 1 600 nm[11].This means that molten pool surface radiation information mainly appears in the band of infrared radiation.

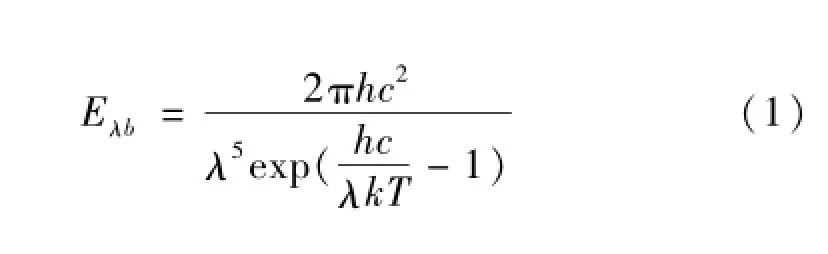

To eliminate interference and obtain clear infrared image of the molten pool,a narrow band pass filter at designated frequency was placed the ahead of camera lens in the experiment.By analyzing the spectrum of molten pool,it was observed that the heat radiation of molten pool mainly covered the near infrared band,while the plasma radiation gathered at the ultraviolet band.By using a combination of the two filters resulting in a spectral band of 960-990 nm,the camera was made sensitive to the molten pool emissions(thermal radiation).Experiments showed that the filter combination led to better molten pool infrared images.The response curves and composite effects of various filters are shown in Fig.1.

Fig.1 Response curves of combination filters

1.2Experimental condition

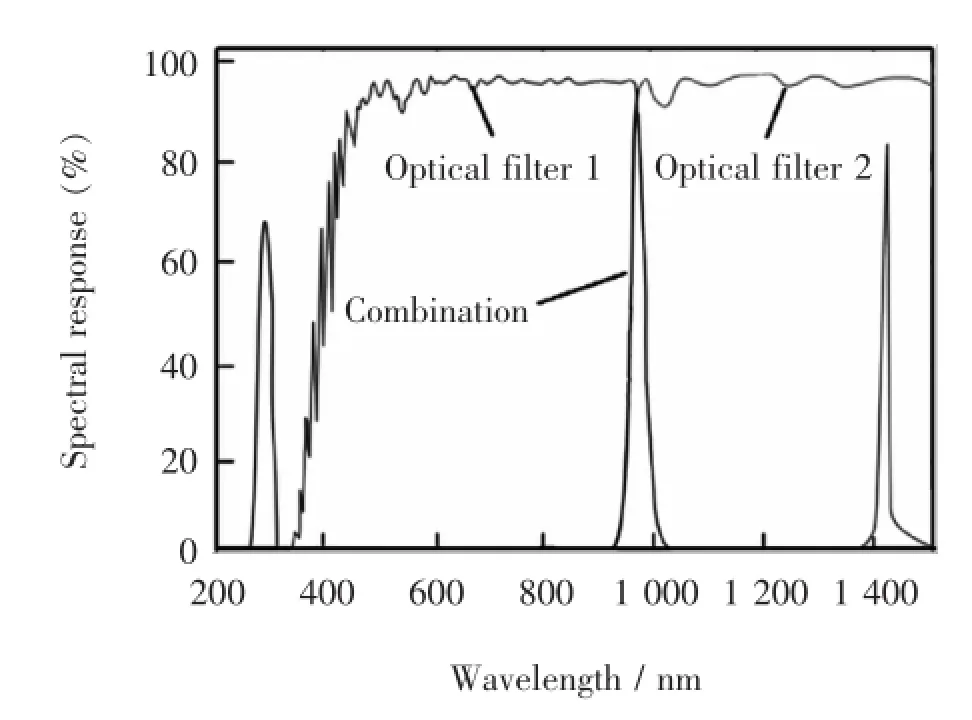

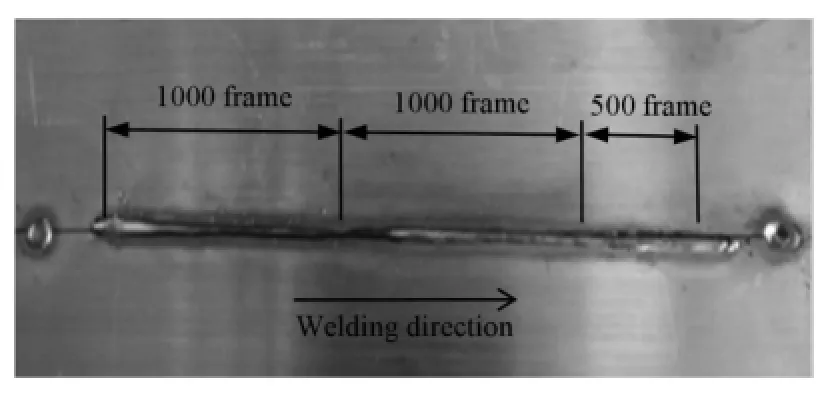

The schematic experimental setup for butt joint laser welding is shown in Fig.2.The top side of welding weldment is shown in Fig.3.In order to research the infrared radiation characteristics of keyhole related to the seam offset between laser beam focus spot and weld seam,the laser beam focus was controlled to move along an oblique line across two stainless plates.An infrared sensitive highspeed camera captured 2 500 frame thermal images of molten pool corresponding to the weld seam of weldment.A continuous wave(CW)fiber laser(IPG YLR-10000)was used for butt joint welding.Welding condition is listed inTable 1.

Fig.2 Experimental setup of fiber laser welding

Fig.3 Top view of three stages of welding process

Table 1 Fiber laser welding conditions

1.3Welding seam position and weld seam extraction

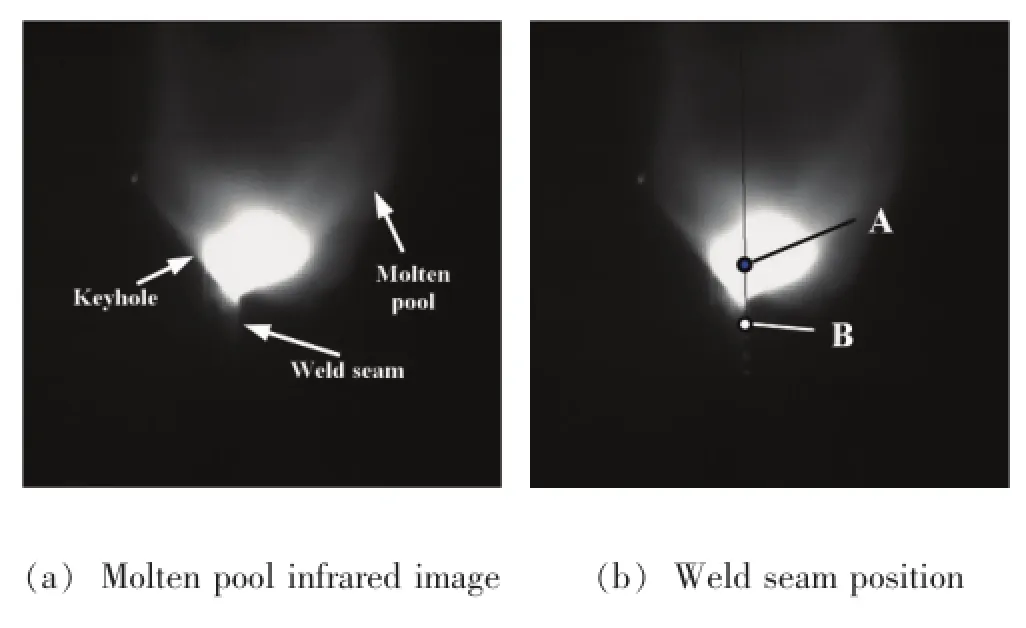

One important step is the extraction of characteristic parameters of weld or keyhole by using visual techniques to identify and track welding seam.In the image of a weldment,the gray level of weld seam is not continuous. The weld seam is a straight line.Fig.4a shows a molten pool infrared image,its size is 512×512 pixel2,the weld seam can be seen clearly.The actual weld seam of each image can be obtained by using the least squares method,as the point B shown in Fig.4b.By calculation,the real position of weld seam in this image is point A(230.77,256).According to the focus point of laser beam was the center point(256,256),there was an actual joint in the center of the image.As a result,we get the actual deviation between laser beams and weld seam.The actual deviation was 25.23 pixels in the image.

Fig.4 Weld seam position of a infrared molten pool image

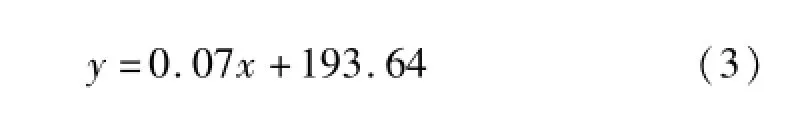

Totally 70 images were selected to measure the actual deviation between laser beam and weld seam.Under the experimental condition,the weld seam was a fixed straight line,as shown dotted line in Fig.5.The linear equation of weld seam was fitted by using the least squares method. Eq.(3)shows the weld seam equation.

where x was the number of images,y was the pixel of images.The laser beam spot focus on the center point(256,256).Combined with Eq.(1),the deviation equation Eq.(4)can be obtained to depict the offset between weld seam and laser beam focus spot.

where x was the number of images,yweld_devwas the devia tion value between laser beam focus spot and weld seam center.

Fig.5 Deviation between laser beam focus and weld seam

1.4Keyhole centroid extraction

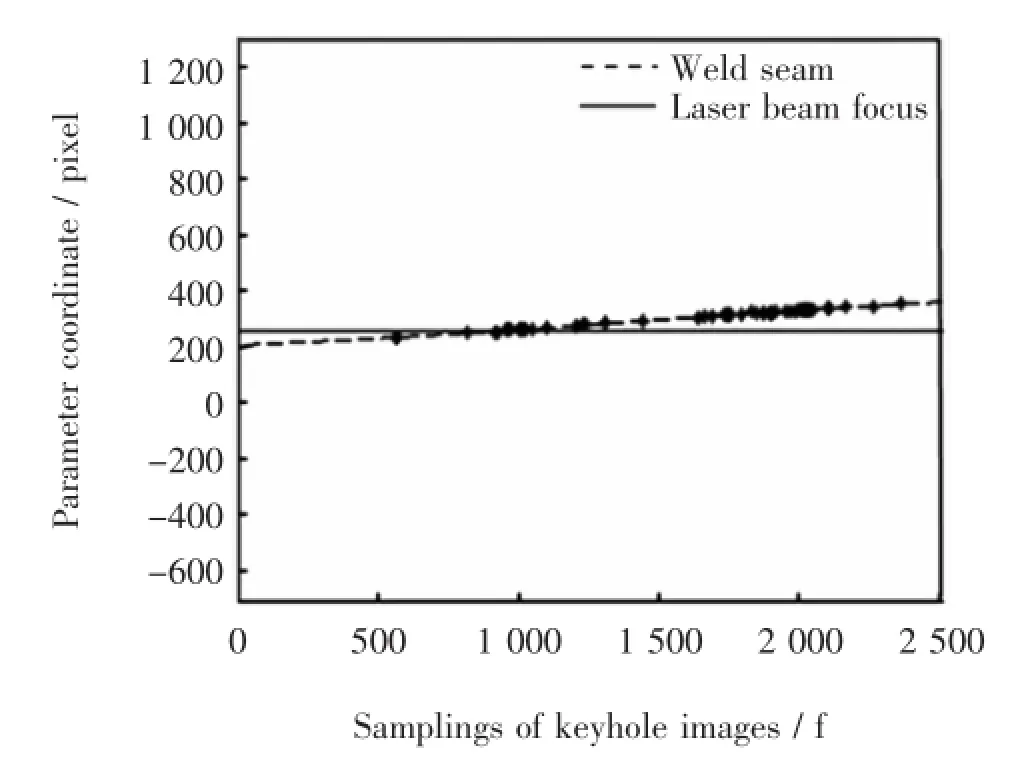

Fig.6a also shows a typical low-resolution metal transfer image which captured with a frame rate 1 000 frames/s.In the welding process,shown in Fig.6b,laser beam focus spot is focused on the weld seam and the weldment is melt to form a keyhole.In the molten pool of infrared images,Fig.6c shows an original keyhole image,the method can be described in two steps.

Step1:Fixed threshold method was used to extract the keyhole of an image.The binary keyhole image was shown in Fig.6b.

Step2:The binary image multiplied by the original gray image obtained keyhole gray image(Fig.6c).

The keyhole centroid in an image is the gravity of images.The calculation formula of keyhole centroid horizontal coordinate X is shown as follows[12].

where i is the abscissa value,j is the value of the vertical ordinate.M is the total row number,N is the total column number and g(i,j)is the gray pixel value of the point(x,y).

Fig.6 Infrared image processing

In welding process,tiny seam still exists between two butt materials.Because heat conductivity is different inthe air and welding materials,heat conduction will have greater“heat resistance”in the weld seam,and produce heat accumulation effect[9].Reflected in the infrared image,the gray level at weld seam has a greater change. Similarly,the keyhole centroid values are significant impacted by the heat accumulation effect.

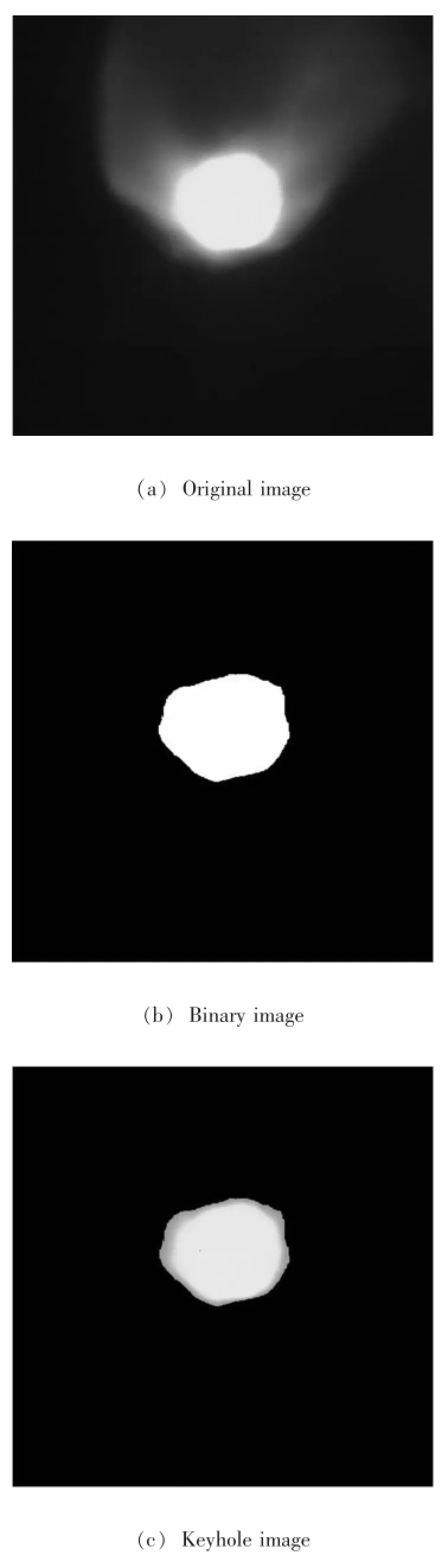

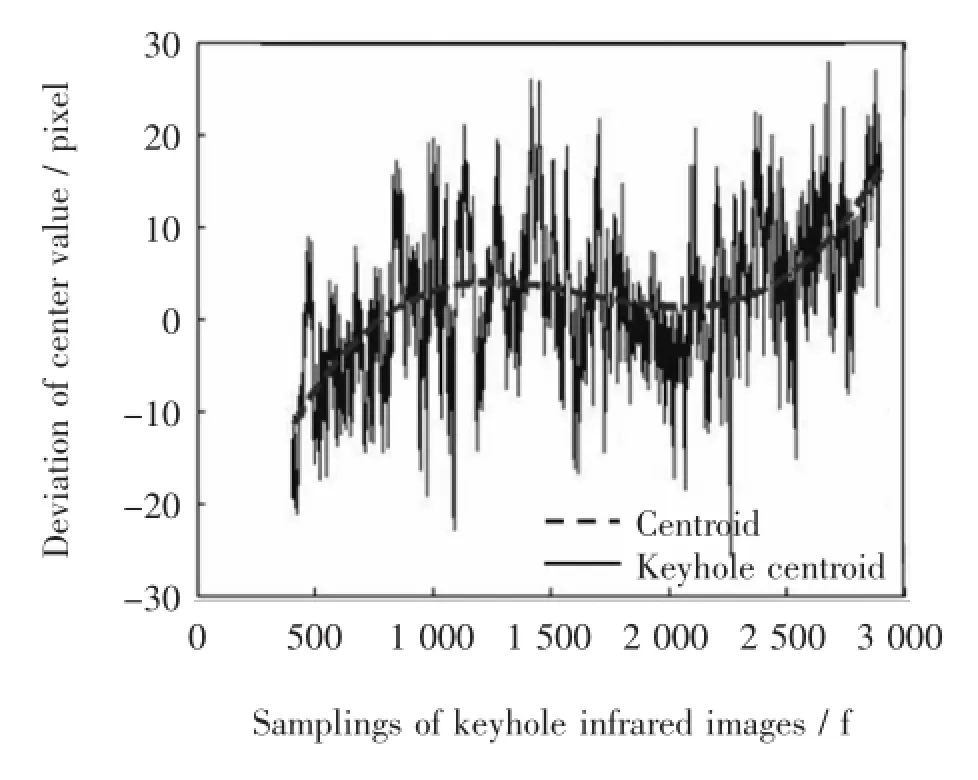

The image centroid reflects the seam offset between laser beam focus spot and weld center.When laser beam is focused on the weld,the gray distribution of keyhole image is symmetrical.The keyhole centroid should be aligned with center line.If the gray distribution of keyhole image is not symmetrical,the keyhole centroid will deviate from center line.So,as long as the quantitative relationship between image centroid and weld position established,the deviation of laser beam focus spot and weld center will be calculate indirectly by the keyhole centroid. Fig.7 shows the horizontal coordinate value of centroid.It can be observed from the surface of weldment in Fig.3 that the laser beam gradually moves down from the top of the weld to the central value in the initial stages in the welding process,which corresponding to about 1 000 images in the analyzed images.At the same time,for existence of the heat accumulation effect,in Fig.7,the keyhole centroid also moves up from the below to center.In the middle stages of welding process,the laser beam almost focus on the center line of weld,it corresponds to No.1001-No.2000 images shown in Fig.7.The keyhole centroid fluctuates around the weld center.In the end of welding process,the laser beam moves to the bottom of weld,which corresponds to No.2001-No.2500 images in Fig.7,for the same reason as initial stages,the keyhole centroid will move from center to the top.According to the experimental results,the keyhole centroid has an increasing trend as the increase of weld offset,so there must be some corresponding relationship between the two.

1.5Offset between keyhole centroid and weld center

As shown in Fig.7,the dotted line,which is fitted by using the least squares method of a cubic curve equation,is the curve equation of keyhole deviation,for all 2 500 images.The keyhole deviation equation is calculated as

where x is the number of images,ykeyhole_devis the keyhole deviation of images.In Fig.7,the fitting curve equation reflects the variation of centroid deviation.The quantitative relationship between keyhole centroid deviation and weld deviation will be established as follows.According to Eq.(4)and Eq.(5),variable x is eliminated,

Eq.(6)is the seam offset equation between keyhole centroid and weld center.

Fig.7 Keyhole centroid fitting curve

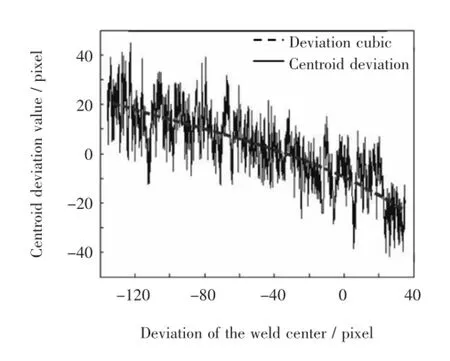

Shown in Fig.8,the dotted line,which is the equation described in Eq.(6),is the seam offset cubic between keyhole centroid and weld center.The solid line is the actual measured value between keyhole centroid deviation and weld deviation.In the initial and the final stage in the welding process,the seam offset equation is matched with the actual measured values.However,in the initial stage,the keyhole centroid deviation exhibits strong fluctuations around the seam offset.Their tendency is inconsistent.The reason is that the heat cumulative effect plays a major role than other factors in the initial stage,where laser beam and weld center have a larger distance. In the middle stage,when laser beam is basically focusedon weld center,heat is eventually spread to each side of weld,and the keyhole centroid deviation ought to be indefinitely approach at zero.In welding process,with the outbreak of plume a lot of weld spatters continue to be produced.And small changes of spatter will lead to substantial fluctuations in the keyhole centroid.The keyhole centroid deviation can not be right reflected by the heat cumulative effect.

Fig.8 Seam offset equation between keyhole centroid and weld center

2 Experimental results

The authors have conducted a series of static experiments to investigate how the weld deviation affects the keyhole centroid of molten pool.Because of the manual limitation in the laser welding process,weld width is operated the range from 0 to 0.1 mm,the laser power is 10 kW,and the welding speed is 2.5 m/min.Welding direction start from the top of weld seam,gradually move on weld center,finally to under of weld seam.As shown in Fig.9 -Fig.10,this was the result of other experiments.

As shown in Fig.10,the dotted line is the seam offset cubic between keyhole centroid and weld center.When weld width is very close to 0,the seam offset cubic curve has degraded close to a straight line.Experimental results demonstrate the welding offset cubic between keyhole centroid and weld center have the corresponding quantitative relationship.

Fig.9 Keyhole centroid fitting curve(weld deviation 0 mm)

Fig.10 Seam offset equation between keyhole centroid and weld center(weld width is close to 0 mm)

3 Conclusions

In the high-power fiber laser butt joint welding of Type 304 stainless steel,according to Planck’s law for black body radiation and Wien law,an infrared sensitive detection system can be applied to capture a pool and keyhole image.After analyzing keyhole centroid characteristic the offset between laser beam focus spot and weld calculated.By analyzing the distribution of keyhole centroid,the relationships between keyhole centroid and heat accumulation effective are illustrated,and a seam offset equation between the keyhole centroid and weld center is established.When the laser beam spot is focused on the center line of weld,the keyhole centroid fluctuates uniformlyaround weld center.Keyhole centroid can be used to judge the seam offset between laser beam focus spot and weld center.

Acknowledgments

Special thanks were given to Katayama Laboratory of Osaka U-niversity for their assistance of laser welding experiments.

[1] Kawahito Y,Kito M,Katayama S.In-process monitoring and adaptive control for gap in micro butt welding with pulsed YAG laser.Journal of Physics D:Applied Physics,2007,40:2972-2978.

[2] Gao X D,Ding D K,Bai T X.Weld-pool image centroid algorithmforseam-trackingvisionmodelinarc-welding process.IET Image Processing,2011,5(5):410-519.

[3] Gao X D,Mo L,Zhong X G,et al.Detection of seam tracking offset based on infrared image during high-power fiber laser welding.Acta Physica Sinica,2011,60(8):737-744.(in Chinese)

[4] Fabbro R.Melt pool and keyhole behavior analysis for deep penetration laser welding.Journal of Physics D:Applied Physics,2010,43:5501-5512.

[5] Beersiek J.A CMOS camera as a tool for process analysis not only for laser beam welding.International Congress on Applications of Lasers&Electro-Optics,Orlando,USA,2001:206-215.

[6] Tsirkas S A,Papanikos P,Kermanidis T.Numerical simulation of the laser welding process in butt-joint specimens. Journal of Materials Processing Technology,2003,134(1):59-69.

[7] Wen P,Zhen S Q,Feng Z H.Prediction of wire transfer behaviors in laser hot wire welding.China Welding,2014,23(1):12-18.

[8] Chen J F,Zhou T H.Experimental study on the shear strength of side fillet weld of Q235B steel post high temperatures.China Welding,2013,22(3):6-11.

[9] Mackwood A P,Crafer R C.Thermal modelling of laser welding and related processes:a literature review.Optics and Laser Technology,2005,37(2):99-115.

[10] Incropera F P,Dewitt D P.Fundamentals of heat and mass transfer.New Jersey:John Wiley&Sons,2006.

[11] Postma S.Weld pool control in Nd:YAG laser welding. Enschede:University of Twente,2003.

[12] Gao X D,Na S J.Detection of weld position and seam tracking based on Kalman filtering of weld of pool images. Journal of Manufacturing Systems,2005,24(1):1-12.

*This work was supported by the Science and Technology Planning Project of Guangzhou,China(No.1563000554),the Science and Technology Planning Major Project of Guangdong Province,China(No.2014B090921008),and the Coordination Innovation and Platform Environment Construction Project of Guangdong Province,China(No.2015B090901013).

**Chen Yuquan and Gao Xiangdong,School of Electromechanical Engineering,Guangdong University of Technology,Guangzhou 510006. Xiao Zhenlin and Chen Xiaohui,Guangzhou Panyu Gofront Dyeing&Finishing Machinery Manufacturer Ltd.Guangzhou,511400. Gao Xiangdong,Corresponding author,E-mail:gaoxd666@126.com

猜你喜欢

杂志排行

China Welding的其它文章

- New filler metal systems for the brazing of titanium alloys

- Effect of gallium addition on microstructure and properties of Ag-Cu-Zn-Sn alloys*

- Influence of Mn on wettability and microstructure of low-silver lead-free solders*

- Plastic characterization and performance of SnAgCuBiNi/Cu lead-free BGA solder joints*

- Macrostructures and mechanical properties of ultrasonic-assisted friction stir welding joint of 2024-T3 aluminium alloy

- Influences of acoustic field parameters on welding arc behavior in ultrasonic-MIG welding*