隔震橡胶支座受弯力学性能研究

2015-06-24沈朝勇马玉宏黄襄云陈洋洋

沈朝勇,马玉宏,黄襄云,陈洋洋,刘 杨,林 佳

(广州大学工程抗震研究中心,广东广州 510405)

隔震橡胶支座受弯力学性能研究

沈朝勇,马玉宏,黄襄云,陈洋洋,刘 杨,林 佳

(广州大学工程抗震研究中心,广东广州 510405)

采用精细有限元分析方法对隔震橡胶支座在压弯、纯弯和拉弯荷载作用的应力及变形特性进行了研究,并与具有相同尺寸混凝土柱的特性进行了对比研究.同时对一些影响因压弯荷载支座所产生的水平位移的因素进行了研究.研究表明,无论是在压弯或拉弯荷载作用下,支座内部都会产生明显的应力集中.除了支座中部孔径大小对支座水平位移幅度影响不大外,其他如支座直径、内部橡胶的剪切模量、内部橡胶总厚度及内部钢板厚度均对其有较大的影响.

隔震橡胶支座;压弯;拉弯;受弯性能;应力集中;水平位移

0 Introduction

Because the elastomeric isolation bearing had a good carrying capacity in the vertical direction,and a very good isolation effect in the horizontal direction, this system was applied widely in buildings or bridges[1],especially after the 1995 Hyogoken-Nanbu Earthquake,this system has been used in nearly 5 000 buildings.In the isolation bridge during the service period,isolation bearings not only need to support the vertical load,but also have a certain rota-tion ability while vehicles running on the bridge,it makes them undertake press-bending load.How about the isolation bearing in this loading condition?

Many studies on the characteristics of rubber bearings under compression or press-shear loading had been performed.For example,SHEN,et al.[2]presented factors effect on the maximum stress of inner steel of rubber bearing under compression.FUJITA,et al.[3]conducted dynamic loading tests of high-damping rubber bearings and proposed analyticalmodelforthehystereticrestoringforce. MASASHI,et al.[4]performed horizontal bidirectional loading tests for real-sized high-damping rubber,the hysteresis loops of these bearings under bidirectional horizontal loadings were compared with those under unidirectional loadings.There are some other literatures about stability of elastomeric isolation bearings.IAN,et al.[5]experimentally researched the stability of elastomeric isolation bearing.JARED. et al.[6]studied the stability of elastomeric and leadrubber seismic isolators,in which the methods of FEM and experiment were adopted.DONATELLO,et al.[7]researched the critical load of slender elastomeric seismic isolators in which the method of experiment was adopted.JAMES,et al.[8]presented an analytical formulation to predict the instability of a rubber bearing affected by cavitation.

Studies on the characteristics of rubber bearings under press-bending loading are few.HE,et al[9]. presented nonlinear rotation and shear stiffness of rubber isolators in which the methods of theory and experiment had been used.On the basis of the nonlinear rotational stiffness and Haringx elastomer model,a simple mechanics model was provided to analyze the rotation,compression and shear property for rubber isolators.In this literature,a useful mechanic model of isolator could consider the property of rotation,compression and shear,but the stress of a useful mechanic model of isolator could consider the property of rotation,compression and shear,but the stress and deformation of elastomeric bearings and deformation of elastomeric bearings under these loading have not been drawn attention.

In this paper,the authors comparatively studied the stress and deformation characteristic of the same size of rubber bearing and concrete column under pure bending or press-bending load.Tension-bending load had also been conducted.In the end,some factor effects on the horizontal displacement caused by press-bending were researched.

1 Bearing specimens

The bearing specimen used in literature[6]was referred to.It is a low-damping natural rubber.It is annular with an outer bonded rubber diameter of 152 mm and an inner diameter of 30 mm.It consists of 20 rubber layers,each 3-mm thick;19 steel shim plates,each 3-mm thick;two steel internal end plates,each 25-mm thick;and a 12-mm thick rubber cover.The total height of bearing is about 167 mm. In the comparison analysis between rubber bearing and concrete column,they are the same size.

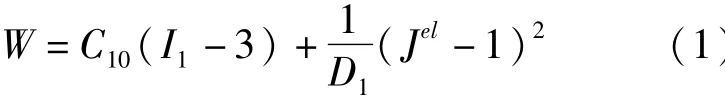

Thegeneral-purposeFEMsoftwarepackage ABAQUS was employed to investigate the property of press-bending or tension-bending of bearings.Threedimensional half-space models of the bearings were developed in ABAQUS,which considered both material and geometric nonlinearity.The rubber components of the bearings were modeled with eight-node continuum(brick)elements(C3D8H)that used a first order hybrid formulation in which pressure and displacement fields are integrated independently to prevent volumetric locking caused by the nearly incompressible behavior of rubber.The Neo-Hookean constitutive model was chosen for the rubber material because of the direct relationship between the model parameters and engineering properties of the rubber. The Neo-Hookean model assumed the rubber to be nonlinear elastic,isotropic and incompressible or nearly incompressible,if a bulk modulus(K)was specified,was defined by the strain energy potential W[6]

in which C10and D1=material parameters equal toG/2 and 2/K,respectively;I1meant the first stress invariant;and Jelmeant the elastic volume ratio.If G=0.74 MPa,then C10=0.37 MPa;the rubber bulk modulus K was assumed to be 2 000 MPa,D1would be equal to 0.001 mm2·N-1.Although the rubber bulk modulus K had not been tested,WARN and WHITAKER showed the FEM solution was insensitive to the value of the bulk modulus for±20%of the assumed value.The steel shims and bearing end plates were discretized with eight-node continuum elements C3D8I.The steel shim plates and bearing end plates were modeled with linear elastic-material properties assuming a Young's modulus(E)of 2.06 MPa and a Poisson's ratio(υ)of 0.3.

Two analysis procedures were used for the FEM investigation:compression or tension and bending. Compression or tension was performed in the first step,then bending performed during the condition of press-bending or tension-bending load.

In the analysis of factors effect on the horizontal displacement caused by press-bending load,different compression,diameters of the inner core,diameters of the outer rubber bearing,G values of the inner rubber,total inner rubber thicknesses,thickness of the single steel shim were considered.The detail values of different factors were listed in Table 1.

Table 1 The values of different factors in the analysis

2 Comparison of rubber bearing and concrete column under the same loading condition

In the isolation building or bridge,there are some same functions for column and isolator,such as supporting the vertical loads,anti-shear in the horizontal direction.As anyone knows there is little difference in the vertical stiffness,but the horizontal stiffness of isolator is far less than that of concrete column with the same size.In the isolation bridge,the isolators are allowed to be a certain rotation angle during service time,and in the isolation building with transfer-structure,the isolators can't avoid to undertake a certain moment.How do they happen on the condition of pure bending,press-bending or tensionbending?What is the difference between rubber bearing and concrete column with the same size?

2.1 Stress and deformation characteristic

In the before-mentioned chapter,there is the detailed description about the isolator specimen.In order to be convenient to compare,the size and internal structure of concrete was the same as the isolator specimen besides the material property.At the same time,there were the same loading conditions and restrains.For the column specimen,C30 was adopted. For the pure bending analysis,0.1 radian rotation angle was applied on both specimens.For the pressbending or tension-bending analysis,5 MPa compression or 3 MPa tension would be imposed on the top of specimens at first,0.1 radian rotation angle was then applied.

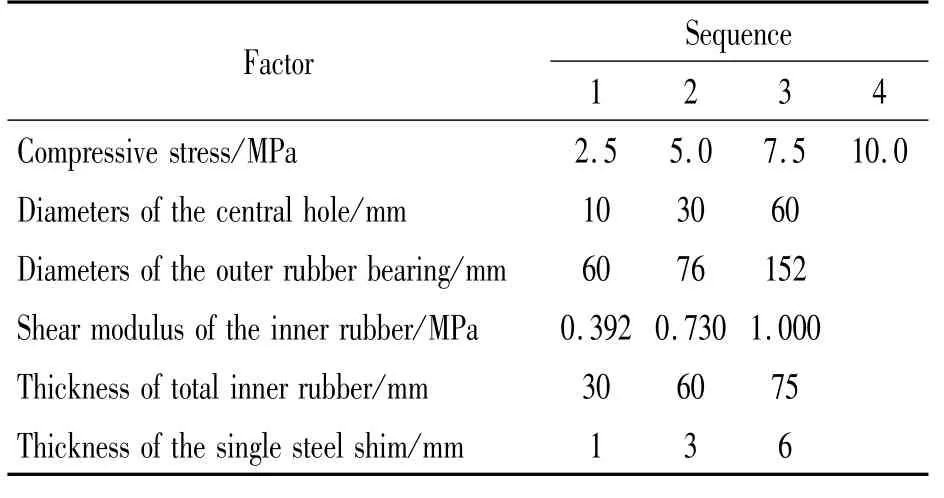

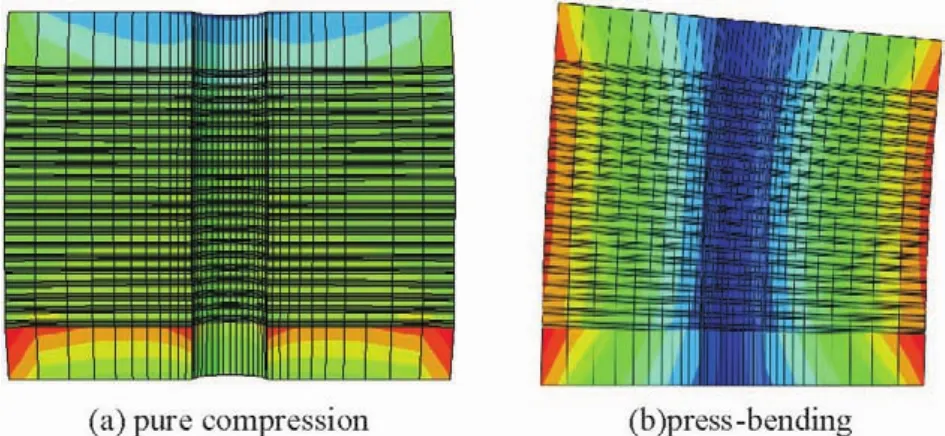

Fig.1 shows comparison of stress characteristic of rubber bearing and concrete column under the pure bending load condition.From this figure,both the last deformation of two specimens could be gained.In this loading condition,the horizontal displacement appeared in both specimens,the value difference between them was very little.But the stress contours show that there is certain remarkable difference.In Fig.1(a),stress contour of rubber bearing at the last loading step shows that there are two obvious areas of concentration stress,these two areas distribute two sides of core,located near the area in the middle of half radius of rubber bearing,and are symmetrical about the central axis of rubber bearing.These two concentration areas form a pair of force couple to anti-bending.In the Fig.1(b),these phenomena can't be found,distribution of stress of concrete column isnearly well-distributed,the maximum stress appears at the outer edge of column.Because concrete column is made up of one homogenous material,the maximum tension or compression will occur at the outer edge of section while pure bending loading. The rubber bearing has entirely different internal structure,and consists of many layers of steel shim plate and rubber,steel shim plate and inner rubber alternately bonds together.When a certain moment was loaded on the rubber bearing,tensile force or pressure would be borne by two parts of bearing beside the hole.Because of the incompressibility of rubber,at the same time,there was no constrain in the core and outside of bearing,under the tensile force or pressure,each inner rubber would cause the adjacent steel shim plate concentration stress in the middle of bearing radius.

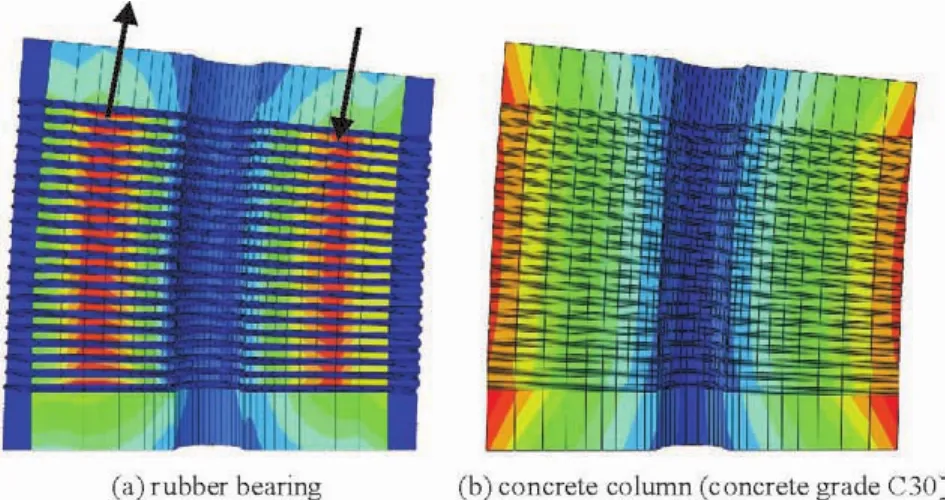

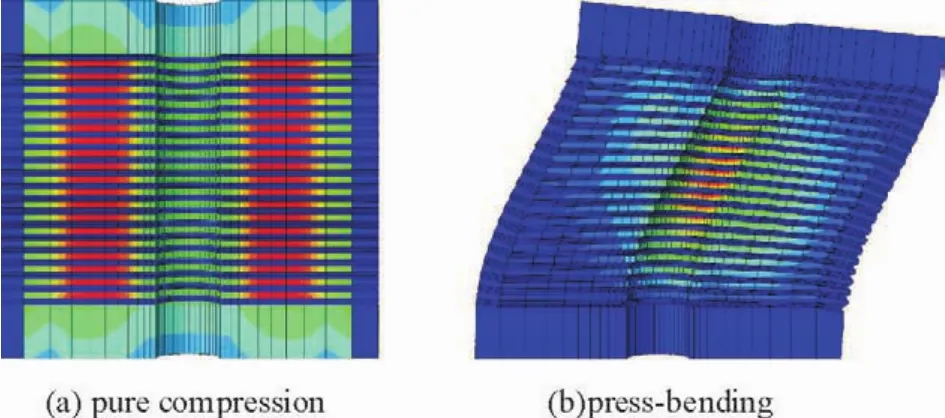

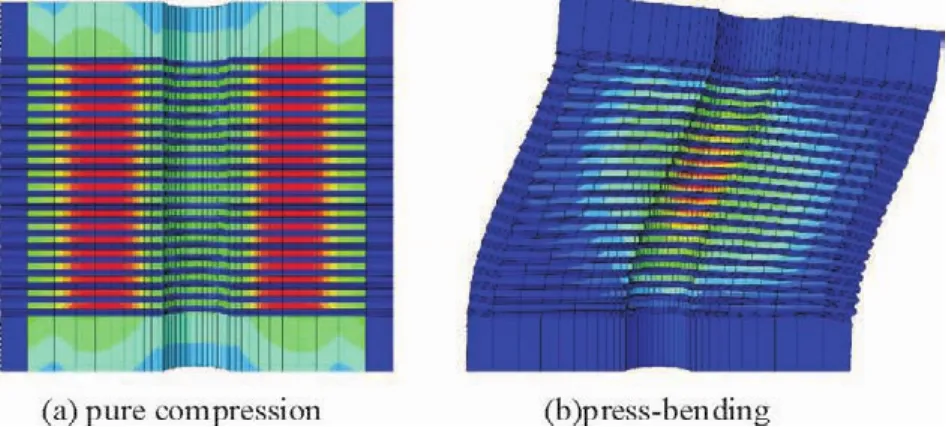

Fig.2,Fig.3 give respectively the stress and deformation characteristic of rubber bearing,concrete column under the pure compression or press-bending conditions.In these figures,Fig.(a)means only under pure compression condition,Fig.(b)means under press-bending conditions.Comparing Fig.2(a)to Fig.3(a),there are apparently different phenomena.In Fig.2(a),the maximum stress locates in the area near the half-radius of bearing and on the steel shim plates.Under the vertical compression,because of the incompressibility of rubber,inner rubbers will extend in the two horizontal directions,one is the outside of rubber bearing,the other is the central hole of bearing,it causes the adjacent steel shim plates near the half-radius of bearing to bear more tension stress.In Fig.3(a),these phenomena can't be found,stress is distributed in the different position as a whole,although there is little stress concentration in the bottom bearing end plate,this phenomenon can be explained that the bottom of bearing was constrained and the vertical size of element of bearing end plate is too big.Comparing Fig.2(b)to Fig.3 (b),firstly,there is apparent difference in the deformation,the horizontal displacement of rubber bearing is larger than that of concrete column.Secondly,there is obvious difference in the stress concentration.For rubber bearing,it is near the central hole in the middle height of bearing,but for concrete column,similar to the pure bending loading,the maximum stress occurs at the edge of concrete column.

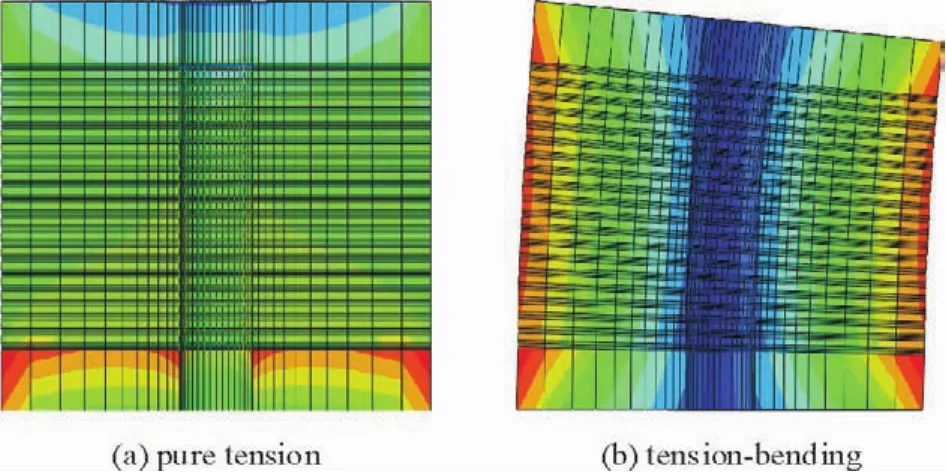

Fig.4,Fig.5 give respectively the stress and deformation characteristic of rubber bearing,concrete column under the pure tension or tension-bending condition.Comparing Fig.2 to Fig.4,Fig.3 to Fig. 5,there are the same stress distribution and deformation respectively.The difference between rubber bearing and concrete column under the tension-bending loading condition is similar to that under the press-bending loading condition mentioned before.

Fig.1 Comparison of stress characteristic of rubber bearing and concrete column under the pure bending condition

Fig.2 Stress and deformation characteristic of rubber bearing under the pure compression or press-bending conditions

Fig.3 Stress and deformation characteristic of concrete column under the pure compression or press-bending conditions

Fig.4 Stress and deformation characteristic of rubber bearing under the pure tension or tension-bending conditions

Fig.5 Stress and deformation characteristic of concrete column under the pure tension or tension-bending conditions

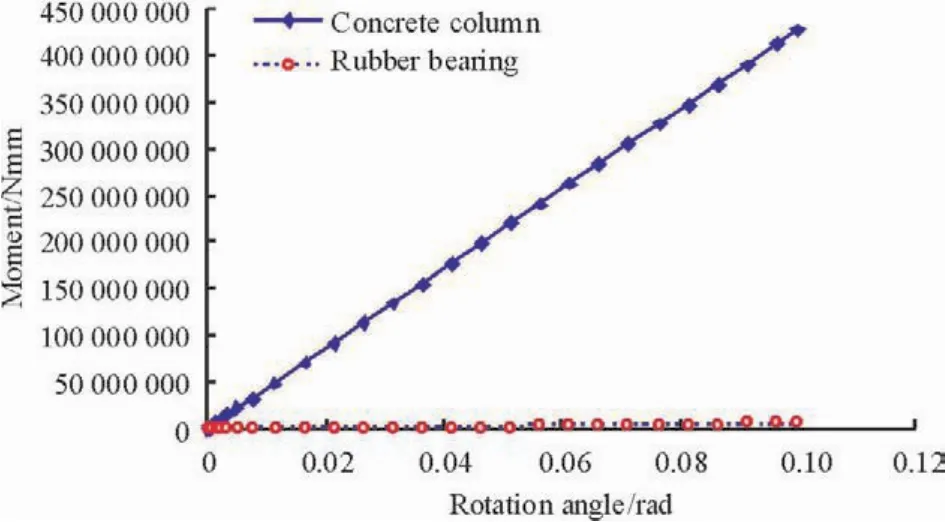

2.2 Rotation stiffness

In FEM model,a reference point was set,all bottom nodes of end plate of bearing were constrained to the reference point.When the rubber bearing was loaded by the press-bending,the reaction force would embody at this reference point.The reaction moment of this reference point was gotten,the corresponding rotation angle of bearing was also given.Rotation angle versus reaction moment of rubber bearing and concrete column were plotted in Fig.6.In this figure,the slope of curve is the stiffness of rotation. Comparing the stiffness of rotation of rubber bearing to that of concrete column,the former is very much less than the latter.According to the FEM results,the anti-bending stiffness of rubber bearing is about 5×107N·mm·rad-1,that of the same section concrete column is 4×109N·mm·rad-1.The former is about one 80th of the latter.This reason is that the tension stiffness of rubber bearing appearing mainly by the inner rubber is very much less than that by concrete column.

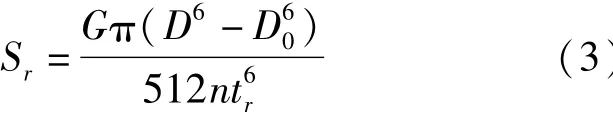

The literature[10-11]gives the formula of rotation stiffness of rubber bearing,as follows:

Fig.6 Comparison of rotation stiffness of rubber bearing and concrete column under the pure bending condition

where,Sris the rotation stiffness of rubber bearing with circular section,G is the shear modulus of inner rubber,D is the diameter of rubber bearing,n is the number of layer of inner rubber,tris the thickness of single layer of inner rubber.According to Eq.(2),the rotation stiffness of the before-mentioned rubber bearing is 5.18×107N·mm·rad-1(only half section can be considered),comparing to the FEM calculation result,there is very little error,less than 10%.In the Eq.(2),the central hole can't be considered,if considered,the equation is the following:

Here,D0is the diameter of the central hole.In the FEM model,the diameter of the central hole is about 30 mm,according to Eq.(3),the rotation stiffness of the rubber bearing is 5.182×107N·mm·rad-1,

this result is compared to the result in which the central hole can't be considered,there lies only 1%error.The diameter of the central hole is 30 mm,less than one fifth of diameter of rubber bearing,according to the comparison result,in this condition,the central hole can be neglected in the calculation of the rotation stiffness of rubber bearing,it means that Eq.

(2)can still be used.

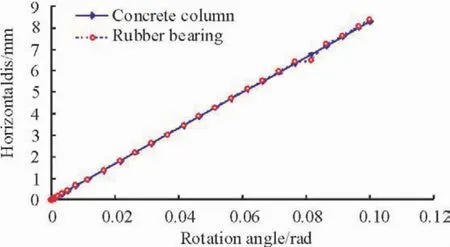

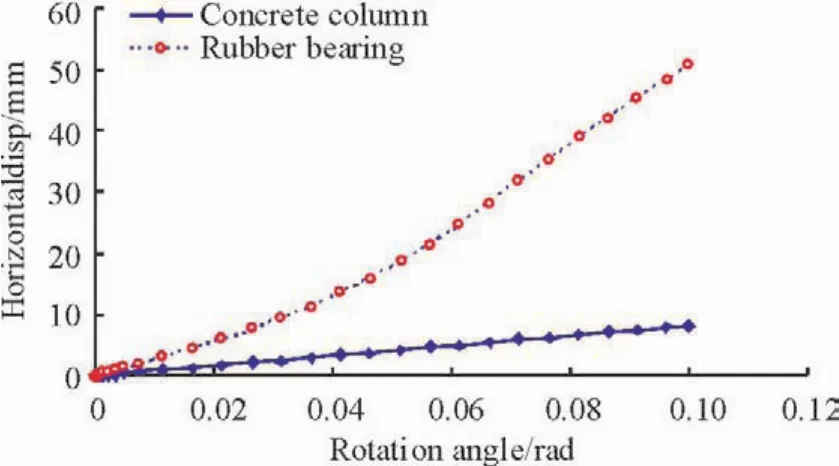

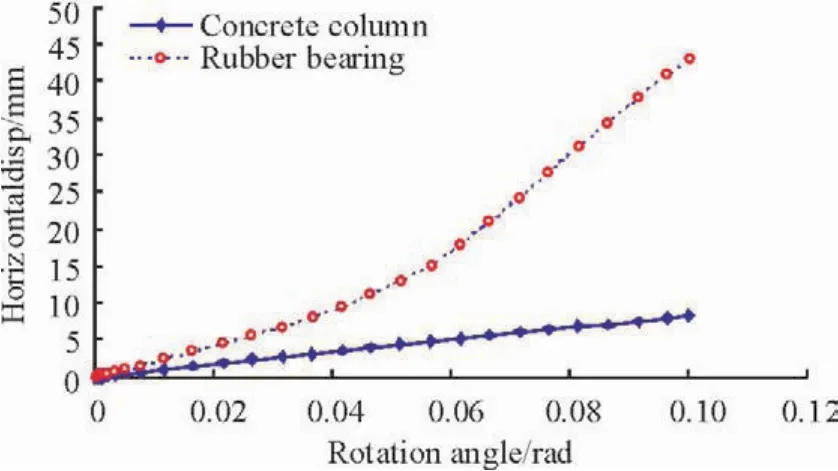

2.3 The rotation-horizontal displacement curve

In Figs.7~9,certain horizontal displacement of rubber bearing or concrete column can be found. What is the difference of magnitude of horizontal displacement when rubber bearing or concrete columnwas loaded with pure bending,press-bending and tension-bending?Figs.7~9 give the detailed difference about the magnitude of horizontal displacement between rubber bearing and concrete column.Fig.7 gives the rotation-horizontal displacement comparison between the concrete column and rubber bearing under pure-bending loading condition.Although there is large difference in the rotation stiffness between concrete column and rubber bearing with the same section size,there is little difference in the horizontal displacement caused by pure bending for the rubber bearing and concrete column(See Fig.7).In Figs.8 ~9,large difference of the horizontal displacement caused by press-bending or tension-bending can be found between concrete column and rubber bearing. For concrete column,whether on the condition of press-bending or tension-bending,the horizontal displacement increases linearly with the rotation angle,these two slopes are approximately equal.But for rubber bearing,both two horizontal displacements caused by press-bending or tension-bending increase nonlinearly with rotation angle,the degree of increasing caused by press-bending is more than that by tension-bending.Comparing concrete column to rubber bearing with the same section size,the displacement of the former is less than that of the latter,the former is about one fifth of the latter.

Fig.8 Rotation-horizontal displacement comparison between the concrete column and rubber bearing under pressbending loading condition

Fig.9 Rotation-horizontal displacement comparison between the concrete column and rubber bearing under tension-bending load

3 Relevant parameters of the horizontal displacementofbearing underthepress-bendingload conditions

3.1 Compressive stress

In Fig.2 and Fig.8,one conclusion can be gotten that a few horizontal displacement was caused by the press-bending loading.What are the factors which affect the magnitude of horizontal displacement?In Table 1,some factors needed to be researched in this chapter have been listed.It mainly includes compressive stress,diameter of the central hole,shear modulus of the inner rubber,thickness of total inner rubber and thickness of the single steel shim.

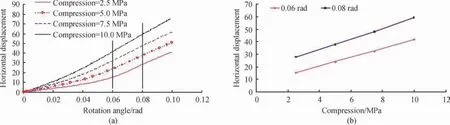

Fig.10 gives the trend of compressive stress effect on the horizontal displacement caused by pressbending load.There are four compressive stress:2.5 MPa,5.0 MPa,7.5 MPa and 10 MPa.When the compressive stress on rubber bearing changed,the other parameters of rubber bearing were unvaried,the maximum rotation angle loaded was still 0.1rad. Under each one compressive stress,the curve of horizontal displacement-rotation angle shows a line withtwo stages,it means the horizontal displacement increases nonlinearly with the rotation angle under each compression load.Comparing different compressive stresses,with compressive stress increasing,the horizontal displacement will increase on a certain rotation angle.For example,when the rotation angle is 0.06 rad,the horizontal displacement is about 15.32 mm,23.83 mm,32.20 mm and 41.74 mm corresponding to 2.5 MPa,5.0 MPa,7.5 MPa and 10.0 MPa;when the rotation angle is 0.08 rad,the horizontal displacement is about 27.99 mm,37.71 mm,47.73 mm and 59.25 mm for different compression.These results were plotted in Fig.10(b).When the same rotation angle is loaded,the horizontal displacement increases linearly with compression increasing.

Fig.10 Effect of compressive stress on the horizontal deformation of rubber bearing

3.2 Diameter of the central hole

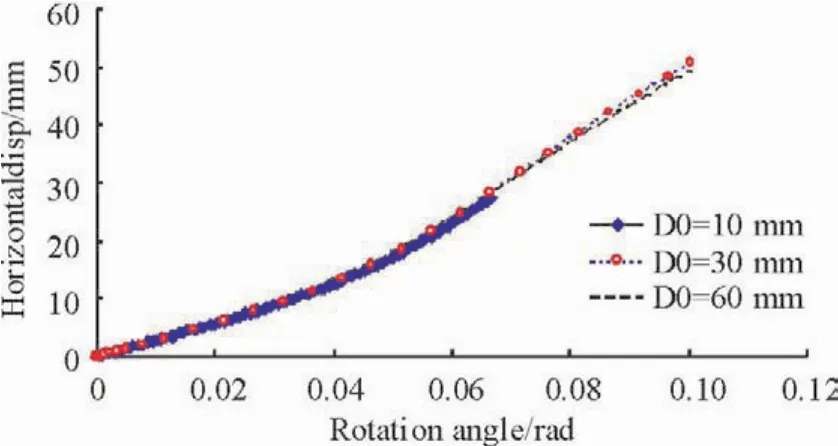

What is the diameter of the central hole D0effect on the horizontal displacement caused by press-bending?There were three diameters of the central hole to be investigated:10 mm,30 mm and 60 mm. When D0changed,other parameters about the rubber bearing kept unvaried,the compression and the maximum rotation angle were still 5.0 MPa and 0.1 rad. Fig.11 gives the trend of D0effect on the horizontal displacement caused by press-bending.For the model of D0equal to 10 mm,because some elements showed abnormal deformation on the last analysis step,the analysis result became no convergence,the maximum rotation was about 0.07 rad in this model. Comparing results of different D0of rubber bearing,Fig.11 shows there is very little difference,it means the diameter of the central hole of rubber bearing has little effect on the horizontal displacement caused by press-bending load.

3.3 Diameter of the rubber bearing

Fig.11 Effect of diameter of central hole on the horizontal deformation of rubber bearing

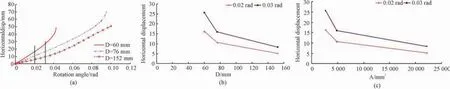

There were three diameters of the rubber bearing (named as D)to be conducted:60 mm,76 mm and 152 mm.When D changed,as the similar to the aforementioned parameters,other parameters about rubber bearing,including loading conditions were kept to be unchanged,especially the diameter of central hole.Fig.12 gives the trend of the diameter of rubber bearing effect on the horizontal displacement response.The three lines show a certain nonlinear characteristic,especially when D is equal to 60 mm or 76 mm,this phenomenon is very obvious at the last stage of the two curves of horizontal displacement-rotation angle.When D was equal to 60 mm,the results showed non convergence at the stage of 0.045 rad angle,and FEM calculation stopped.In order to investigate the detail relationship between the diameter of rubber bearing and the horizontal displacement response,those displacements in Fig.12 (a)corresponding to the rotation angle equal to 0.02rad or 0.03 rad had been extracted,and had been plotted in Fig.12(b).As seen in Fig.12(b),regardless of the rotation angle equal to 0.02 rad or 0.03 rad,it shows strong nonlinearity of horizontal displacement-diameter of rubber bearing,it especially lies in the stage in which D is equal to 60 mm to 76 mm.The tendency shows the horizontal displacement decreases with D increasing.Fig.12(c)gives the curves of horizontal displacement-area of rubber bearing,here,the area of the central hole had been eliminated from the area of rubber bearing.It shows there are similar laws between the diameter of rubber bearing and the area of that. F

ig.12 The effect of diameter or area of isolator on the horizontal deformation of rubber bearing

3.4 G value of the inner rubber

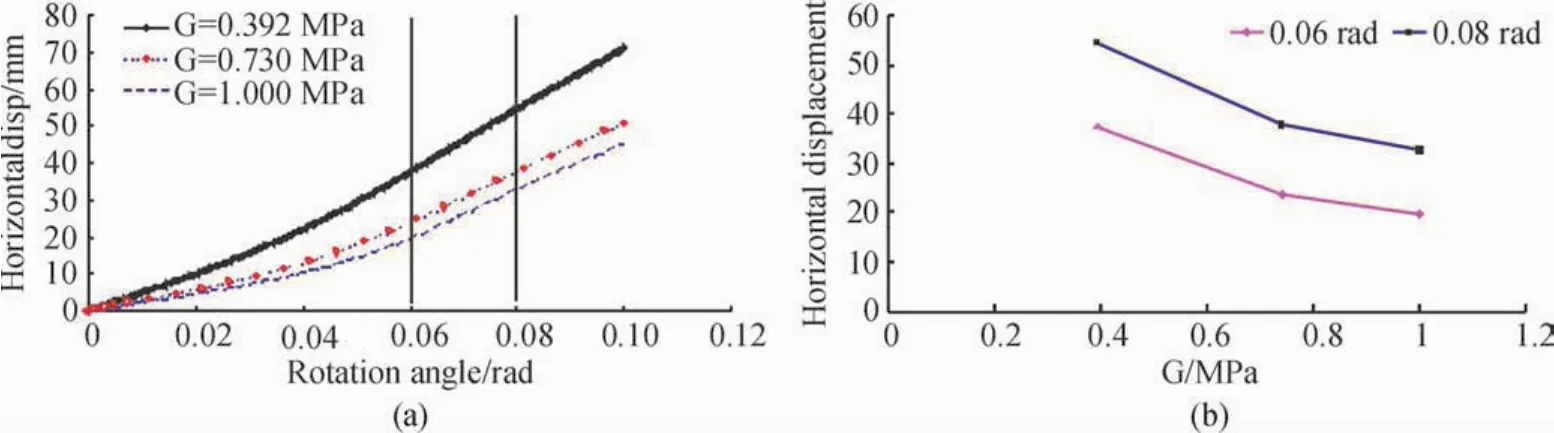

As similar to the diameter of rubber bearing,three different shear modulus(named as G)values of inner rubber were investigated.Fig.13(a)exhibits the trend of G value effect on the horizontal displacement caused by press-bending load.The three lines show the nonlinear characteristic in Fig.13(a),the difference of the horizontal displacement between G value 0.392 and 0.730 MPa is more than that between G value 0.730 MPa and 1.000 MPa.In order to conduct the reality law of G value effect on that,as similar to the parameter compression,horizontal displacements at the rotation angle equal to 0.06 rad and 0.08 rad had been extracted,and plotted in Fig. 13(b).As seen in Fig.13(b),the horizontal displacements of rubber bearing change nonlinear with the G value changing,while G value increasing,the displacements decrease.

3.5 Total thickness of all inner rubber

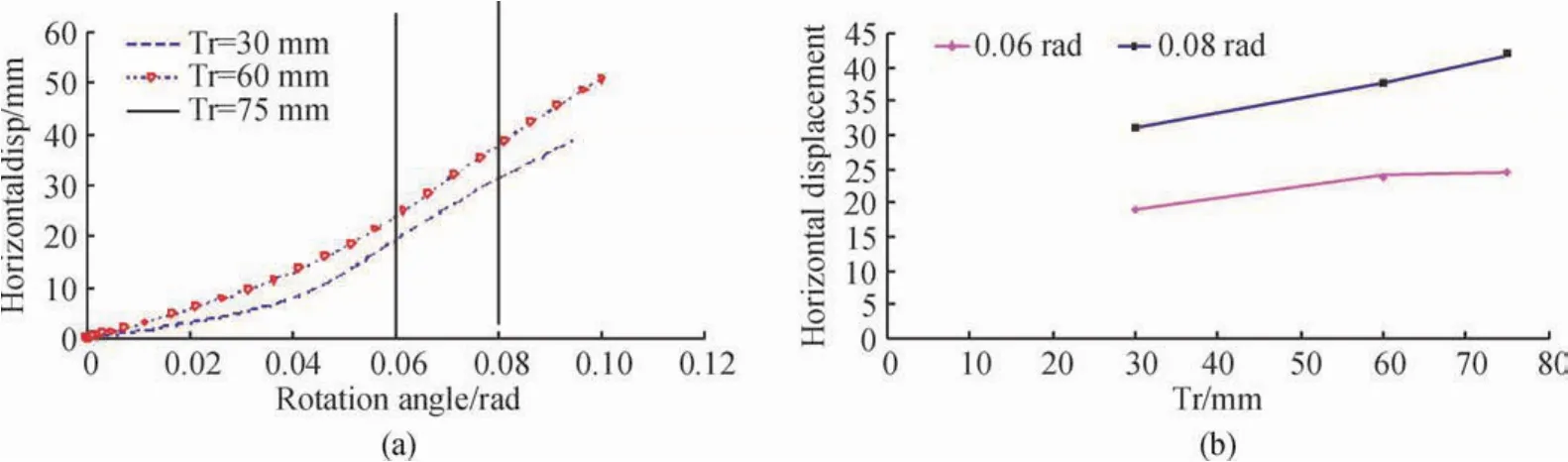

Three total thickness of inner rubber(named as Tr)were selected to investigated,there were 30 mm,60 mm,75 mm respectively.Fig.14 shows that total thickness of inner rubbers has a certain effect on the magnitude of the horizontal displacement of rubber bearing.If Tris thicker,the magnitude of the horizontal displacement of rubber bearing becomes larger.In order to investigate the law of Treffect on the magnitude of horizontal displacement of rubber bearing,horizontal displacements at the rotation angle equal to 0.06 rad and 0.08 rad had been selected(Fig.14(b)).As seen in Fig.14(b),when the rotation angle is 0.06 rad or 0.08 rad,there is a little difference about the law of the horizontal displacement-Trcurve,although all of the horizontal displacement increases with Trincreasing.As in 0.06 rad condition,the relative increment of horizontal displacement is about 24.6%,when Trrises from 30 mm to 60 mm,that is about 2.7%when Trrises from 60 mm to 75 mm.On the other hand,the slope at the first stage is about 0.008,that at the second stage is 0.002,it means there is no uniform slope during the two stages,and the law of horizontal displacement-Trshows a certain nonlinearity in 0.06 rad condition.As in 0.08 rad condition,the relative increment of horizontal displacement is about 21.3%,when Trrises from 30 mm to 60 mm,that is about 11.4%when Trrises from 60 mm to 75 mm.On the other hand,the slope at the first stage is about 0.007,that at the second stage is 0.007,it means that there is a uniform slope during the two stages,and the law of horizontal displacement-Trshows a certain linearity in 0.08 rad condition.Comparing the law of horizontal displacement-Trbetween 0.06 rad condition and 0.08 rad condition,it seems to be inconsistent phenomenal.

Fig.13 The effect of shear modulus on the horizontal deformation of rubber bearing

Fig.14 The effect of total thickness of inner rubbers on the horizontal displacement of rubber bearing

3.6 Thickness of the steel shim plate

Fig.15 shows the trend of the thickness of the steel shim plate(names as ts)effect on the horizontal displacement of rubber bearing caused by press-bending.As seen in Fig.15,when the rotation angle is less than 0.03 rad,in spite of tsdifference,the displacements seem to be indifferent under the same rotation condition;when the rotation angle is more than 0.03 rad,there is a little difference in the horizontal displacement of rubber bearing with different tsvalues,all of the law of horizontal displacement-rotation for rubber bearing with different tsshows a certain nonlinear characteristic,but there is difference about the degree of the nonlinearity,the most nonlinearity appears when the tsof rubber bearing is 1 mm,the least to be 6 mm.As similar to other parameter analysis,the horizontal displacement in condition of rotation angle equal to 0.06 rad or 0.08 rad had been chosen,they were plotted in Fig.15(b).

Fig.15 Different thickness of the single steel shim plate effect on the horizontal deformation of rubber bearing

As seen in Fig.15(b),when the rotation angle is 0.06 rad or 0.08 rad,there is also a little difference about the detail law of the horizontal displacement-tscurve,although all of the horizontal displacement decreases with tsincreasing.As in 0.06 rad condition,the relative increment of horizontal displacement is about-17.8%,when tsrises from 1 mm to 3 mm,that is about-16.7%when tsrises from 3 mm to 6 mm.As in 0.08 rad condition,the relative increment of horizontal displacement is about -8%,when tsrises from 1 mm to 3 mm,that is about-24.5%when tsrises from 3 mm to 6 mm.In 0.06 rotation condition,the slope at the first stage is about-0.09,that at the second stage is-0.06;in0.08 rotation condition,the slope at the first stage is about-0.04,that at the second stage is-0.08;it means there is no uniform slope during the two stages whether in 0.06 or 0.08 rotation condition,the difference lies that the absolute value of the slope of the horizontal displacement-tsat the second stage is less than that at the first stage in the 0.06 rad condition,vice versa in the 0.08 rad condition.

4 Conclusions

An analysis has been presented in this paper for the bending mechanical property of elastomeric isolation bearing.On the basis of this investigation,the following conclusions can be drawn:

(1)Other than the concrete column with the same section size,there is a significant stress concentration in the steel shim plates of rubber bearing under pure bending load,which locates near the halfradius of bearing position.At the same time,the same phenomena also appear under press-bending load condition or tension-bending load condition,but the stress concentration moves to the area near the central hole.

(2)Under press-bending or tension-bending load condition,a few horizontal displacements will come into being.

(3)The bending stiffness of rubber bearing is much less than that of concrete column with the same size,the former is about the one 80thof the latter.

(4)Except the diameter of central hole,many factors have an effect on the horizontal displacement of rubber bearing under press-bending load,such as compressive stress,diameter of rubber bearing,shear modulus of the inner rubber,total thickness of the inner rubber,thickness of the steel shim.Among these factors,except that compress stress has the linearly effect,other factors have a significant nonlinear effect on the horizontal displacement of rubber bearing.

[1] ZHOU F L.Earthquake energy absorbing control on engineering structure[M].Beijing:Seismological Press,1997:29-30. (in Chinese)

[2] SHEN C Y,ZHOU M H,ZHUANG X Z,et al.Research on stresses of steel plates of isolator with large diameter and low IRHD rubber under vertical loading[J].J Disa Prev Miti Engin,2011,31(1):30-37.(in Chinese)

[3] FUJITA T,SUZUKI S,FUJITA S.High damping rubber bearing for seismic isolation of building:(1st report)hysteretic restoring force characteristics and analytical models[J].Trans JSME,1990,C56:658-666.(in Japanese)

[4] MASASHI Y,SHIGE0M,ARUMI Y,et al.Nonlinear behavior of high-damping rubber bearings under horizontal bidirectional loading:full-scale tests and analytical modeling[J].Earthq Engin Struct Dyna,2012(41):1845-1860.

[5] IAN B,SATISH N,KEITH F.Stability of elastomeric isolation bearings:experimental study[J].J Struct Engin,2002,128(1):3-11.

[6] JARED W,GORDON P W.Stability of elastomeric and lead-rubber seismic isolation bearings[J].J Struct Engin,138(2):215-222.

[7] DONATELL0C,GIUSEPPE P.Critical load of slender elastomeric seismic isolators:An experimental perspective[J].Engin Struct,2012,40:198-204.

[8] JAMES M K,MARIA R M.Tension buckling in rubber bearings affected by cavitation[J].Engin Struct,2013(56):656-663.

[9] HE W F,LIU W G,YANG Q R,et al.Nonlinear rotation and shear stiffness theory and experiment research on rubber isolators[J].J Engin Mech,2012,138(5):441-449.

[10]IS022762-2:2005 Elastomeric seismic-protection isolators-Part 2:Applications for bridges-Specifications,MOD.[S]

[11]GB 20688.2 2006.Rubber bearings:part 2:Elastometric seismic protection isolators for bridges[S].(in Chinese)

【责任编辑:周 全】

Bending mechanical property of elastomeric isolation bearings

SHEN Chao-yong,MA Yu-hong,HUANG Xiang-yun,CHEN Yang-yang,LIU Yang,LIN Jia

(Earthquake Engineering Research&Test Center,Guangzhou University,Guangzhou 510405,China)

In this paper,stress and deformation characteristic of rubber bearing under pure-bending,press-bending and tension-bending had been investigated,concrete column with the same size as the rubber bearing had been listed to compare.Some factors which might affect the magnitude of horizontal displacement of rubber bearing caused by press-bending load had been investigated.Analysis shows that there is a significant stress concentration in the rubber bearing,whether under the press-bending or tension-bending.Except the diameter of central hole,there are many factors which have much more effect on the magnitude of horizontal displacement,such as the diameter of rubber bearing,shear modulus of inner rubber,total thickness of inner rubbers,thickness of the steel shim plate.

isolation bearing;press-bending;tension-bending;bending mechanical property;stress concentration;horizontal displacement

ET 471

:A

date:2015-04-29; Revised date:2015-05-12

s:National Basic Research Program of China(973 2011CB013606),the twelfth-Five National Support Plan Projects (2012BAJ07B02),Nation Union Fund of China(1334209)and the National Science Foundation of China(91315307-07)

TU 317+.1;TU 352.1;P 315.92;P 315.8

A

1671-4229(2015)05-0034-10

Biography:SHEN Chao-yong(1972-),male,associate professor,Ph.D.E-mail:shency@gzhu.edu.cn