Effect of Starch Dodecenylsuccinylation on the Adhesion and Film Properties of Dodecenylsuccinylated Starch for Polyester Warp Sizing

2014-08-12LIChanglong李长龙BAOLeZHUZhifeng祝志峰

LI Chang-long (李长龙), BAO Le (鲍 乐), ZHU Zhi-feng (祝志峰)

1 Anhui Key Laboratory of Textile Materials, College of Textiles and Garments, Anhui Polytechnic University, Wuhu 241000, China 2 College of Textiles and Garments, Jiangnan University, Wuxi 214122, China

Effect of Starch Dodecenylsuccinylation on the Adhesion and Film Properties of Dodecenylsuccinylated Starch for Polyester Warp Sizing

LI Chang-long (李长龙)1, BAO Le (鲍 乐)1, ZHU Zhi-feng (祝志峰)2*

1AnhuiKeyLaboratoryofTextileMaterials,CollegeofTextilesandGarments,AnhuiPolytechnicUniversity,Wuhu241000,China2CollegeofTextilesandGarments,JiangnanUniversity,Wuxi214122,China

A series of dodecenylsuccinylated starches (DSSs) with different degree of substitution (DS) were prepared via the esterification of dodencenylsuccinic anhydride with hydrolyzed cornstarch in aqueous dispersion for investigating the influences of starch dodecenylsuccinylation upon the performances such as apparent viscosity and surface tension of starch paste, film behaviors, and adhesion to fibers for warp sizing. It was found that the dodecenylsuccinylation was able to reduce the surface tension of cooked starch paste and enhance the adhesion of starch to polyester fibers. It was also capable of depressing the brittleness of native starch and improving the mechanical behaviours such as breaking elongation and work-to-break of starch film. Initial increase in DS level of dodecenylsuccinylation enhanced these positive effects, while excessively increasing the level resulted in marked reduction in tensile strength of starch film and significant decrement in reaction efficiency. X-ray diffraction patterns of starch films showed the dodecenylsuccinates derivatized onto the backbones of starch depressed the degree of crystallinity of starch film. Based on the paste behaviors, adhesion, and film properties, the dodecenylsuccinylation level is recommended in a range of 0.015-0.025 for sizing polyester warps.

warpsizingagent;esterifiedstarch;dodecenylsuccinylation;adhesion;filmbehaviour

Introduction

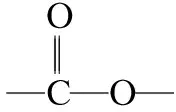

Dodecenylsuccinylated starch (DSS) can be prepared via the dodecenylsuccinylation of starch with dodecenylsuccinic anhydride (DDSA)[1], as illustrated in Scheme 1. This dodecenylsuccinylation is usually carried out in aqueous dispersion of starch under mild alkaline or harsh acidic conditions[2]. Compared with its native counterpart, DSS shows valuable properties such as reduced gelatinization temperature, good film-forming properties, and stable viscosity at lower temperatures[3-4]. After modified with DDSA, the normally hydrophilic starch gains a hydrophobic element in the form of dodecenyl groups, resulting in whole molecules with an amphipathic character. The dodecenylsuccinates attached onto starch backbone impart surface-activity to the derivatives[5]. This activity makes the DSS be useful in many ultimate applications like food, paper making, and pharmaceutical products[4].

Scheme 1 Chemical equation of starch with DDSA

Based on the properties mentioned above, DSS exhibits potential use in sizing polyester-containing warps. However, the study on the performance of DSS for the warps was quite limited. Little was known about the modification extent of DSS used for sizing the warp. Therefore, the aims of this study were to examine the effect of the dodecenylsuccinylation on the properties of DSS and determine how heavily the dodecenylsuccinylation should be performed. Accordingly, we made our efforts toward studying the influence of degree of substitution (DS) upon apparent viscosity, emulsion activity, starch film, and adhesion-to-fibers because these performances are often related to the level of starch modification. Furthermore, it is very important to maintain the insolubility of starch granule during various chemical modification and purification[6]. This insolubility makes starch modification possible by using simple equipment and water as the only solvent. Accordingly, we only took the techniques that can maintain the integrity of starch granules during the dodecenylsuccinylation.

1 Experimental

1.1 Materials

Commercial cornstarch, supplied by Xingmao Cornstarch Development Co., Ltd. (Zhucheng, Shandong Province, China) had an apparent viscosity of 48 mPa·s. Prior to starch dodecenylsuccinylation, the viscosity was depressed with hydrochloric acid to 8 mPa·s in accordance with a literature method[7]. The DDSA, an analytical pure reagent, was obtained from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). Chemicals such as hydrochloric acid, sodium hydroxide, and absolute ethanol were all analytical pure reagents.

Polyester roving (365 tex, 49.8 in twist factor) was kindly supplied by Yizheng Chemical Fiber Co., Ltd. (Yizheng, Jiangsu Province, China). Fiber length and fineness of the roving were 38.0 mm and 1.73 dtex, respectively. The partially hydrolyzed polyvinyl alcohol (PVA) used for the comparison with DSS in adhesion test was obtained from Shanghai Yingjia Industry Development Co., Ltd., China.

1.2 Dodecenylsuccinylation of starch

Hydrolyzed starch (HS) was dodecenylsuccinylated to different DS via the reaction of the starch with DDSA. The starch was dispersed with 243 mL of distilled water with agitation to form a 40% aqueous dispersion of starch. After being adjusted to pH 8.5 by adding 3% by weight NaOH solution, the dispersion was heated to 40 ℃ under mechanical stirring. The DDSA was diluted five times by volume with absolute alcohol and the solution was added slowly over 1 h. The reaction was carried out under continuous stirring at 40 ℃ for 4 h. Meanwhile, the pH of the mixture was maintained to 8.5 with the NaOH solution. After reaction, the dispersion was neutralized to pH 6.5-7 with 3% by weight HCl solution, and the starch was filtered, washed three times with ethanol/water mixture (70/30 by volume), dried at 45 ℃ in an oven, and pulverized for passing a 100-mesh sieve.

1.3 Characterization of DSS

The DS value of DSS was measured by a titrimetric method[8]. Briefly, 3.0 g of DSS (dry weight, exactly weighed) was suspended into 25 mL of ethanol (95%, by volume). And 30 mL of 2.5 mol/L HCl solution was added to the suspension and stirred for 30 min. Then, the DSS was filtered, washed with ethanol/water mixture (70/30 by volume) to such an extent that no chlorine ions existed in the filtrate (detected by AgNO3). The DSS was dispersed with 200 mL of distilled water, boiling-cooked for 30 min, and titrated with 0.1 mol/L NaOH standard solution using phenolphthalein as an indicator. A blank was simultaneously titrated with native starch and the difference between them assumed to be due to chemically bound dodecenylsuccinate groups. The mass fraction (W, %) and DS of dodecenylsuccinate substituents were calculated through Eqs. (1) and (2):

(1)

(2)

whereV1andV2were the volumes (mL) of NaOH standard solution consumed in blank (native starch) and sample titration, respectively;m1andm2were the dry weights (g) of native starch and DSS, respectively;c(mol/L) was the concentration of the standard solution;W(%) was the mass fraction of dodecenylsuccinates in starch; andMwas the molecular weight of dodecenylsuccinates.

The FTIR spectra were recorded by an IRPrestige-21 FTIR Spectrometer (Shimadzu Co., Japan) to examine the change in chemical structure of starch before and after dodecenylsuccinylation. For the measurement, the specimens were powdered by grinding native starch and DSS with KBr, respectively, and then pressed into discs. The spectra were recorded over a wave number range between 400 and 4000 cm-1.

1.4 Paste viscosity

Apparent viscosity and viscosity stability of cooked starch paste were measured with an NDJ-79 Viscometer (Electrical Machinery Plant of Tongji University, Shanghai, China) at the time of 1 h after starch gelatinization under a concentration of 6% by weight at 95 ℃. The cooking of starch and the measurements on its viscosity and stability were in accordance with FZ/T 15001—2008, a criterion regulated by China Textile Association.

1.5 Surface tension

Measurement on surface tension of cooked starch pastes was performed by a DCAT-11 Tensiometer (Dataphysics Instruments GmbH, Germany). Starch was pasted by dispersing starch into distilled water to form 0.5%, 1%, and 3% by weight dispersions, respectively. The dispersions were heated to 95 ℃ and the pastes obtained were stirred at 95 ℃ for 1 h, and left to cool down before being tested. The data reported were the average of 5 successful tests.

1.6 Adhesion to fibers

The adhesion of starch to fibers was accessed with a roving method. The method was first adopted by Faasen and Van Harten to evaluate the adhesion of a sizing agent to fibers in 1966[9], and it has now been regulated to a standard (FZ/T 15001—2008) in China. Based on this regulation, roving was used as adherent and impregnated with a 1% by weight starch paste at 95 ℃, and air-dried. And such sized roving was subjected to a drawing test to failure. It was the failure forces that were adopted to access the adhesion[10-11]. The measurement was briefly described as follows.

Starch was pasted under a mass concentration of 1% by heating it to 95 ℃ and the paste obtained was mechanically stirred at this temperature for 1 h. Then, the roving carefully wound onto a frame was impregnated with the paste at 95 ℃ for 5 min and the impregnated roving was air-dried. After having been kept at 65% relative humidity (RH) and 20℃ for 24 h, the sized roving was drawn by an Instron 3365 Material Tester (Instron Co., USA) for determining its tensile force and work-to-break. The drawing test was performed with an initial chuck-distance of 100 mm and a drawing speed of 50 mm/min under the same atmosphere condition as the moisture balance of the sized roving. In each case, 30 pairs of the force and work were tested for calculating their average and coefficient of variation, among which the abnormal values had been rejected by statistical analysis.

1.7 Measurements on starch film

Starch film was cast from a cooked starch paste. Briefly, 24 g of starch (dry base) was suspended into 376 mL of distilled water, and the suspension was heated to 95 ℃ and mechanical stirred at the temperature for 1 h. Then, the paste obtained was completely poured onto a 650 mm × 400 mm polyester film spread onto a same-sized glass plate and air-dried at 65% RH and 20 ℃. The film formed was cut into strips with the sizes of 200 mm × 10 mm. The strips were kept under the same atmosphere as film formation for 24 h before being tested.

Tensile properties such as tensile strength, breaking elongation, and work-to-break of these starch films were measured on an Instron 3365 Material Tester (Instron Co., USA) using 200 mm × 10 mm strips. The measurement adopted an initial chuck-distance of 100 mm and a drawing speed of 50 mm/min. Twenty samples were measured to obtain their average and coefficient of variation for each of the data reported.

X-ray diffraction patterns of starch films were measured using an XRD-6000 X-ray Diffractometer (Shimadzu Co., Japan) operated at 35 kV and 20 mA with monochromatic Cu-Kα radiation (wavelength = 0.15406 nm). Broken films were packed tightly in a rectangular glass cell and scanned at a scanning rate of 1(°)/min from the diffraction angle (2θ) 4° to 40° with a step size of 0.02°at room temperature. The degree of crystallinity was calculated according to Eq. (3)[12]:

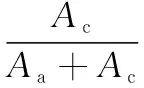

(3)

whereXcwas the degree of crystallinity, andAcandAawere the crystalline and amorphous areas on the X-ray diffractogram, respectively.

1.8 Determinations on PVA

The degree of hydrolysis (DH) and the volatile fraction (VF) of partially hydrolyzed PVA used for contrast were determined with the national standard (GB 12010.5—89). The measured DH and VF of partially hydrolyzed PVA used were 88.2% by mole and 1.57%, respectively.

Molecular weight of the PVA was determined with a Waters Breeze Gel Permeation Chromatography (GPC 1515, Waters Corporation, USA). A Waters 600 (Waters, USA) high performance liquid chromatography system was equipped, using a Waters 2745 refractive index detector and a Waters empower 3 chromatography workstation. Chromatographic separation was achieved on two Ultrahydrogel Linear chromatography columns (250 mm in length and 4.6 mm in internal diameter, Waters, USA) at 30℃. During separation, DMF was used as a mobile phase and the flow rate was 4.2 mL/min. The measured molecular weight of PVA was converted to degree of polymerization from Eq. (4).

(4)

whereMnwas the molecular weight of partially alcoholized PVA measured with GPC, andmwas the weighted average of molar weight of constitutional units in PVA molecular chains.

2 Results and Discussion

2.1 Characterization of DSS

The FTIR spectra of HS and DSS (DS=0.031) are shown in Fig.1. Two new characteristic bands were observed in the spectra of DSS besides characteristic bands of HS. The new band at 1724 was assigned to the stretching vibration of ester carbonyl[13-14], and the band at 1564 cm-1corresponded to the asymmetric stretching vibration of carboxylic salt[1, 15]. These new bands indicate the incorporation of dodecenylsuccinates onto the backbones of starch.

Fig.1 FTIR spectra of (a) HS and (b) DSS

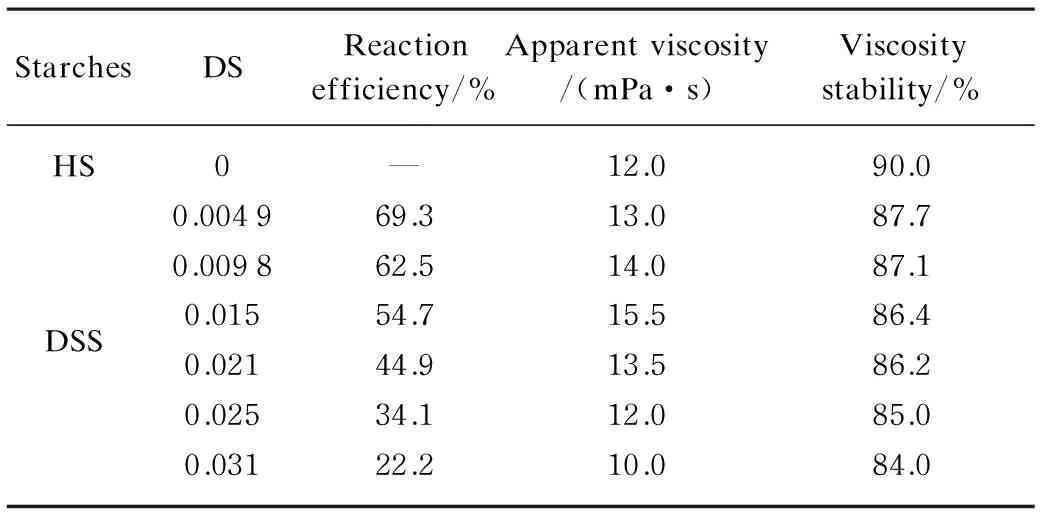

Effect of the amount of DDSA used on the reaction efficiency of starch dodecenylsuccinylation is shown in Table 1. It could be seen that with the increase in the amount, the DS of DSS increased gradually while the efficiency of reaction of DDSA with starch decreased continuously. The decrement in the efficiency at higher DS level is probably due to the reduction in reaction sites of starch granules. As the dodecenylsuccinylation goes on, active sites on surface of starch granules are gradually occupied by the dodecenylsuccinates introduced, and there may be not adequate sites for further introducing dodecenylsuccinates. As a result, a large amount of DDSA has to react with the hydroxyls inside the granules through diffusion. Meanwhile, some of DDSA may hydrolyze with water. Accordingly, a reduced efficiency is observed at higher amount of DDSA used. Obviously, extremely low efficiency at higher DS level constitutes a limitation for further increasing the DS of DSS.

Table 1 Characterization of DSS prepared

2.2 Effect on viscosity

Table 1 also shows the effect of starch dodecenylsuccinylation on apparent viscosity and viscosity stability of cooked DSS paste. It was observed that with the increase of the DS, the viscosity increased initially, reached the maximal value (15.5 mPa·s) at 0.015, and then decreased gradually. Generally, the DSS had a relatively low paste viscosity, much lower than maleinated starch (with hydrophilic succinates) in paste viscosity. The viscosities of maleinated starch are 24 and 53 mPa·s at the DS of 0.018 and 0.036, respectively[16]. Hydrophilic carboxyls introduced onto starch chains by starch maleation are hydrophilic and ionizable, and are capable of enhancing intermolecular interaction between starch and water and increasing intramolecular repulsion through ionization, thereby leading to further swelling of broken fragments derived from starch granules and greater expansion of starch coils in continuous phase. The expansion and swelling enhance the kinetic volumes of broken fragments and starch coils, and result in an increased resistance to paste flow. Therefore, the viscosity of maleinated starch is greater than that of HS. Starch dodecenylsuccinylation is known to introduce dodecenylsuccinates onto the backbones of starch. The difference of the introduced subsituents between DSS and maleinated starch is the dodecenyl. Hydrophobic dodecenyl decreases swelling power in aqueous medium and reduces the expansion of starch coils in continuous phase. Consequently, the viscosity of DSS shows an ascending tendency compared with that of maleinated starch. As the DS increases, the enhanced hydrophobicity imparted by the increased amount of dodecenyls provides stronger inhabitation to the swelling and expansion, and a reduced viscosity is logical.

In addition, viscosity stability of cooked starch does not vary greatly after the dodecenylsuccinylation. The stabilities were all over 85% until the DS reached 0.025. This feature meets the requirement of sizing operation on the stability and supplies a base for achieving a stable size add-on during sizing operation.

2.3 Effect on the adhesion

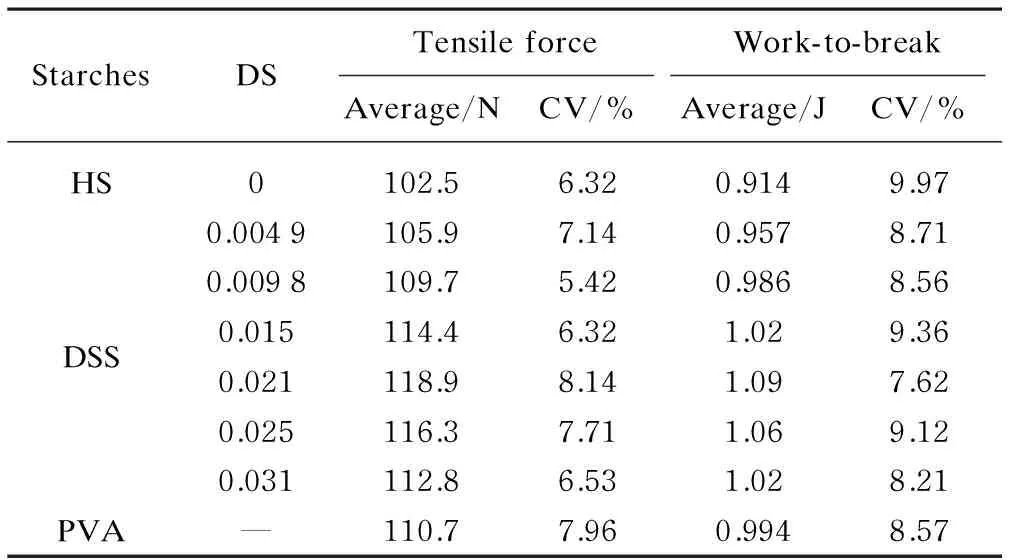

Weaving efficiency and breakage of warp yarns during weaving are greatly dependent on the adhesion of a sizing agent to fibers. High adhesion is preferred since it lays a foundation for substantially increasing warp strength and reducing hairs on warp yarns. Accordingly, the effect of starch dodecenylsuccinylation on the adhesion is estimated. The effects of starch dodecenylsuccinylation on the adhesions of DSS to polyester fibers are illustrated in Table 2.

Table 2 Effects of the dodecenylsuccinylation on the adhesions of starch to polyester fibers

Note: for the PVA sample used, the determined DH was 88.2% by mole and measured DP was 599

It could be observed that the dodecenylsuccinylation showed positive effect on the adhesion. The force and work of polyester roving treated with DSS were significantly greater than with HS. This implies the dodecenylsuccinylation is able to enhance the adhesion to polyester fibers. Furthermore, the adhesion depended on the dodecenylsuccinylation level. The force and work of polyester roving treated with DDSA increased initially with the increase of DS value, reached their maximal values (118.9 N and 1.09 J) at 0.021 in the DS, and then decreased gradually.

Furthermore, surface tension of cooked starch paste is also closely related to the adhesion because it not only determines the impregnation of the paste into yarns, but also affects wetting and spreading of the paste onto fibers. Therefore, surface tension of cooked DSS paste was measured, as shown in Fig.2. It could be seen that the tension decreased as the DS increased. Obviously, the decrease in surface tension is mainly attributed to the introduction of long amphipathic dodecenylsuccinates onto the backbones of starch. It can be imagined that lower tension improves the wetting of starch paste onto fibers and may reduce incomplete spreading and interfacial defects. Accordingly, stress concentration around unwetted interfacial defects decreases, thereby decreasing the possibility of interfacial failure. For this reason, the decrease in surface tension is another reason to improve the adhesion of DSS to polyester fibers.

Fig.2 Surface tensions of cooked DSS paste under different concentrations

When modified with excessive amount of DDSA, the normally hydrophilic starch paste gains hydrophobicity. Direct evidence is the decrement in apparent viscosities at higher DS values, as shown in Table 1. As is well known, water-dispersibility plays an important role for a water-based adhesive since a badly dispersed adhesive never give good wetting and spreading. The hydrophobicity undoubtedly reduces water dispersibility of cooked starch paste and thus damages the wetting and spreading. As a result, stress concentration occurs around unwetted or outspreaded areas. Accordingly, the adhesion decreases at higher DS values.

The adhesion of the partially hydrolyzed PVA to polyester fibers was measured for the comparison with the DSS, as shown in Table 2. The PVA is a widely acceptable product and is widely used for sizing various polyester yarns nowadays. Accordingly, the PVA was adopted as control sample for evaluating the adhesion of DSS to polyester fibers. Comparison on the adhesion between the PVA and DSS showed that the DSS had good adhesion to the fibers. The DSS was stronger than the PVA in the adhesion when its DS value reached and exceeded 0.015. It can be imagined that this strong adhesion of DSS will play an important role in improving the quality of sized polyester warps.

2.4 Effect on film properties

During weaving, the function of starch film on surface of spun yarns is to protect the yarns from mechanical abrasion exerted by machinery parts and neighboring ends for improving weaving efficiency of various looms. The film will display the function until it is worn out from sized yarns. Obviously, a tougher and stronger film is preferred to prolong the protection particularly for brittle and rigid starch. In order to access the performance of DSS, tensile properties of starch film were evaluated.

Influence of starch dodecenylsuccinylation on tensile properties of DSS film is shown in Table 3. With the increase in the DS, breaking elongation and work-to-break of DSS film increased whereas tensile strength of the film decreased. The increases in breaking elongation and work-to-break imply the reduction in brittleness and rigidity for starch film. Therefore, the dodecenylsuccinylation is capable of toughing starch film for reducing its brittleness and rigidity. The adverse impact of the modification on starch film is the decrement in tensile strength of the film.

Table 3 Effect of the dodecenylsuccinylation on tensile properties of starch film

X-ray diffraction was analyzed to reveal the reason why the modification was capable of toughening starch film. Figure 3 shows X-ray diffraction patterns of starch films cast from HS and DSS. It was not surprised to find a reduced degree of crystallinity of starch film after the dodecenylsuccinylation. The degree of crystallinity of the HS was 13.48%, whereas the degree of crystallinity of the DSS decreased to 7.84%. The decrease suggested that the dodecenylsuccinates could prevent the formation of the crystalline structure of starch film to some extent. Obviously, the dodecenylsuccinates introduced interfere with the association of starch hydroxyls and disturb regular arrangement of starch chains within the matrix of starch film due to their steric effect. It is the effect that weakens the hydrogen bonds between molecules, leads to a decreased degree of crystallinity and thus results in internal plasticization for DSS film, thereby increasing the elongation of starch film. However, the substituents introduced onto the backbones of starch reduce the amount of hydrogen bonds, increase the distance between starch chains, and interfere with regular arrangement of starch chains. Consequently, a reduced tensile strength can be imagined. With the increase in the DS, more substituents are introduced, thus raising the plasticization.

Fig.3 X-ray diffraction patterns of starch films cast from (a) HS and (b) DSS

It is as well to emphasize that native starch film is brittle since it has a very low elongation, but a strong strength. This insufficient elongation often causes starch film rupture on surface of sized yarns and induces size shedding and lint. The shedding damages integrity of sizing film and reduces the protection to warp yarns. It is proposed that breaking elongation, if too low, will affect weaving more adversely than low strength because starch film must withstand repeated and extensive bending during weaving operation. Therefore, the increase in breaking elongation is preferred for starch sizing agents.

3 Conclusions

This observation demonstrates that starch dodecenylsuccinylation is an effective method to improve the performance of cornstarch for sizing polyester yarns. The dodecenylsuccinylation reduces surface tension of cooked starch paste, thereby promoting the impregnation of cooked starch paste into warp yarns, ameliorating wetting and spreading of the paste on fibers, and increasing the adhesion of starch to polyester fibers. In addition, the dodecenylsuccinylation shows toughening effect on starch film. Compared with the film cast from the dodecenylsuccinate-free counterpart, DSS film displays a larger breaking elongation and a greater work-to-break, but a slightly lowered tensile strength. Furthermore, the dodecenylsuccinylation neither presents much impact on apparent viscosity of cooked starch paste nor significantly influences its paste stability. These improvements supply a base for DSS to be used as warp sizing agents. The DS value is one of the most important parameters to determine the performances of DSS. Properly increasing the DS is able to improve the performance of DSS for sizing polyester warp yarns. However, excessively increasing the value is not advisable due to significant reduction in tensile strength of DSS film and notable decrease in reaction efficiency. Maximum adhesion is observed at the DS of 0.021. Based on the paste behaviors, adhesion, and film properties, the dodecenylsuccinylation level is recommended in a range of 0.015-0.025 for sizing polyester warp yarns.

[1] Chi H, Xu K, Xue D H,etal. Synthesis of Dodecenyl Succinic Anhydride (DDSA) Corn Starch [J].FoodResearchInternational, 2007, 40(2): 232-238.

[2] Jeon Y S, Viswanathan A, Gross R A. Studies of Starch Esterification: Reactions with Alkenylsuccinates in Aqueous Slurry Systems [J].Starch/Stärke, 1999, 51(2/3): 90-93.

[3] Ren L L, Jiang M, Tong J,etal. Influence of Surface Esterification with Alkenyl Succinic Anhydrides on Mechanical Properties of Corn Starch Films [J].CarbohydratePolymers, 2010, 82(3): 1010-1013.

[4] Hu H Y, Tan Y B, Shi J,etal. Advances of Starch Sodium Dodecenylsuccinate [J].PopularScience&Technology, 2012, 14(10): 59-60, 44. (in Chinese)

[5] Vries H J D, Semeijn C, Buwalda P L. Emulsifier Prepared Using a Glycosyl Transferase: US, 8178323B2 [P]. 2012.

[6] Tessler M M, Billmers R L. Preparation of Starch Ester [J].JournalofEnvironmentalPolymerDegradation, 1996, 4(2): 85-89.

[7] Zhu Z F, Qian K. Effects of the Molecular Structures of Polyvinyl Alcohol on the Adhesion to Fiber Substrates [J].FibersandTextilesinEasternEurope, 2007, 15(1): 82-85.

[8] Ma B J, Tang H B. Synthetical Technology of Starch Dodecenylsuccinate [J].JournalofNortheastForestryUniversity, 2005, 33(3): 78-79.

[9] Jin E Q, Zhu Z F, Yang Y Q,etal. Blending Water-Soluble Aliphatic-Aromatic Copolyester in Starch for Enhancing the Adhesion of Sizing Paste to Polyester Fibers [J].JournaloftheTextileInstitute, 2011, 102(8): 681-688.

[10] Zhu Z F, Li M L, Jin E Q. Effect of Allyl Pretreatment of Starch on the Grafting Efficiency and Properties of Allyl Starch-G-Poly(Acrylic Acid) [J].JournalofAppliedPolymerScience, 2009, 112(5): 2822-2829.

[11] Zhu Z F, Cheng Z Q. Effect of Inorganic Phosphates on the Adhesion of Mono-Phosphorylated Cornstarch to Fibers [J].Starch/Stärke, 2008, 60(6): 315-320.

[12] Miao M, Zhang T, Mu W M,etal. Structural Characterizations of Waxy Maize Starch Residue FollowinginvitroPancreatin and Amyloglucosidase Synergistic Hydrolysis [J].FoodHydrocolloids, 2011, 25(2): 214-220.

[13] Thygesen L G, Løkke M M, Micklander E,etal. Vibrational Microspectroscopy of Food. Ramanvs. FT-IR [J].TrendsinFoodScience&Technology, 2003, 14(1/2): 50-57.

[14] Zhou J, Ren L L, Tong J,etal. Surface Esterification of Corn Starch Films: Reaction with Dodecenyl Succinic Anhydride [J].CarbohydratePolymers, 2009, 78(4): 888-893.

[15] Rivero I E, Balsamo V, Müller A J. Microwave-Assisted Modification of Starch for Compatibilizing LLDPE/Starch Blends [J].CarbohydratePolymers, 2009, 75(2): 343-350.

[16] Wang M,Zhu Z F. Effect of Maleic Anhydride-Esterification of Starch on the Properties of Starch Sizes [J].JournalofTextileResearch, 2013, 34(5): 53-57. (in Chinese)

[17] Zhang, K. Interface Science of Polymers [M]. Beijing: China Petrochemical Press, 1996: 130-136. (in Chinese)

[18] Zhu Z F, Chen P H. Carbamoyl Ethylation of Starch for Enhancing the Adhesion Capacity to Fibers [J].JournalofAppliedPolymerScience, 2007, 106(4): 2763-2768.

[19] Wu S H. Polymer Interface and Adhesion [M]. New York: Marcel Dekker Inc., 1982: 359- 477.

the Fund of Anhui Province Science Research Projects, China (No. 1106b0105062); the Research Foundation Program of Scientific and Technological Innovation Team of College and University at the Provincial Level of Anhui, China (No. TD200710)

1672-5220(2014)06-0747-06

Received date: 2013-12-31

* Correspondence should be addressed to ZHU Zhi-feng, E-mail: zhuzhifengwu@sina.com.cn

CLC number: TS103.84 Document code: A

猜你喜欢

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Optimization of Quality Consistency Problem of Electromechanical Component due to Manufacturing Uncertainties with a Novel Tolerance Design Method

- Interval Fault Tree Analysis of Excavator Variable-Frequency Speed Control System

- Combinatorial Optimization Based Analog Circuit Fault Diagnosis with Back Propagation Neural Network

- Reliability Allocation of Large Mining Excavator Electrical System Based on the Entropy Method with Failure and Maintenance Data

- Deployment Reliability Test and Assessment for Landing Gear of Chang’E-3 Probe

- Reliability Analysis of Hydraulic Transmission Oil Supply System of Power-Shift Steering Transmission with GO Methodology