Enhancing Biogas Production from Anaerobically Digested Wheat Straw Through Ammonia Pretreatment*

2014-07-18YANGDongyan杨懂艳PANGYunzhi庞云芝YUANHairong袁海荣CHENShulin陈树林MAJingwei马晶伟YULiang郁亮andLIXiujin李秀金CenterforResourcesandEnvironmentalResearchBeijingUniversityofChemicalTechnologyBeijing0009ChinaBeijingMunicipalEnvironmentalMoni

YANG Dongyan (杨懂艳), PANG Yunzhi (庞云芝), YUAN Hairong (袁海荣), CHEN Shulin (陈树林), MA Jingwei (马晶伟), YU Liang (郁亮)and LI Xiujin (李秀金),**Center for Resources and Environmental Research, Beijing University of Chemical Technology, Beijing 0009, ChinaBeijing Municipal Environmental Monitoring Center, Beijing 00044, ChinaDepartment of Biological Systems Engineering, Washington State University at Pullman, WA 9964-60, USA

Enhancing Biogas Production from Anaerobically Digested Wheat Straw Through Ammonia Pretreatment*

YANG Dongyan (杨懂艳)1,2, PANG Yunzhi (庞云芝)1, YUAN Hairong (袁海荣)1, CHEN Shulin (陈树林)3, MA Jingwei (马晶伟)3, YU Liang (郁亮)3and LI Xiujin (李秀金)1,**

1Center for Resources and Environmental Research, Beijing University of Chemical Technology, Beijing 100029, China2Beijing Municipal Environmental Monitoring Center, Beijing 100044, China3Department of Biological Systems Engineering, Washington State University at Pullman, WA 99164-6120, USA

Aqueous ammonia was used to pretreat wheat straw to improve biodegradability and provide nitrogen source for enhancing biogas production. Three doses of ammonia (2%, 4%, and 6%, dry matter) and three moisture contents (30%, 60%, and 80%, dry matter) were applied to pretreat wheat straw for 7 days. The pretreated wheat straws were anaerobically digested at three loading rates (50, 65, and 80 g·L−1) to produce biogas. The results indicated that the wheat straw pretreated with 80% moisture content and 4% ammonia achieved the highest methane yield of 199.7 ml·g−1(based on per unit volatile solids loaded), with shorter digestion time (T80) of 25 days at the loading rate of 65 g·L−1compared to untreated one. The main chemical compositions of wheat straw were also analyzed. The cellulose and hemicellulose contents were decomposed by 2%-20% and 26%-42%, respectively, while the lignin content was hardly removed, cold-water and hot-water extracts were increased by 4%-44%, and 12%-52%, respectively, for the ammonia-pretreated wheat straws at different moisture contents. The appropriate C/N ratio and decomposition of original chemical compositions into relatively readily biodegradable substances will improve the biodegradability and biogas yield.

wheat straw, anaerobic digestion, biogas, ammonia pretreatment, moisture content

1 INTRODUCTION

With frequent occurrence of extreme weather and climate, the global warming has become a great challenge to the world. It has been commonly accepted that the existing energy systems need to be changed. The renewable energy is one of energy alternatives and friendly to the environment, but it only accounts for 14% of the total energy consumption nowadays [1]. Lignocellulosic biomass is one of very promising and attractive energy feedstocks, which can be converted to heat, steam, electricity, hydrogen, biogas, and liquid biofuel through appropriate technologies. The application of biomass energy as alternative will greatly reduce CO2emission and global warming.

Wheat straw is one of lignocellulosic biomasses from agriculture, with annual production of 110 million tons in China [2]. Wheat straw could be converted to bioenergy through various biological processes. Anaerobic digestion (AD) is a widely used technology for converting organic wastes to biogas [3, 4]. However, as a kind of biomass material rich in lignocellulose, the recalcitrant of cellulose and hemicellulose limits the effective conversion of wheat straw to biogas. Additional nitrogen source needs to be added to adjust C/N ratio within the optimal range of 25-30 when using wheat straw as sole substrate, as raw wheat straw contains higher carbon and lower nitrogen source [5].

Pretreatment can reduce recalcitrance of biomass by breaking down the macroscopic rigidity of biomass, removing part of hemicellulose and lignin, which in turn improves the accessibility for cellulose and diminishes the crystallinity of cellulose [6-9]. Commonly used pretreatment methods include size reduction, steam explosion, fungi biodegradation, acidic and alkaline treatment. Alkaline pretreatment has been proven to have practical advantages over others for its relatively lower cost, higher efficiency, and easier operation [10-12]. Aqueous ammonia is selected in this study as pretreatment reagent, as it potentially gives similar efficiency with other alkali and provides additional nitrogen source for subsequent anaerobic bacteria digestion [13, 14], which may significantly reduce the cost of operation. Our group has applied preliminary experiment with ammonia pretreatment to improve biogas production of rice straw, with biogas increased by 38.3% [15]. This study is a continuation of the previous one.

The objective of this study is to investigate the effect of ammonia pretreatment on biogasification of wheat straw and determine optimal parameters for pretreatment and anaerobic digestion. The main chemical compositions in the pretreatment are also analyzed to investigate the mechanisms for improving the biodegradability and biogas production.

2 MATERIALS AND METHODS

2.1 Raw materials

The wheat straw used in this study was obtained from a corn field in Shunyi District of Beijing, China.The wheat straw was naturally dried and chopped, then ground into 5-10 mm particles. It contained 95.6% total solids (TS), 85.6% volatile solids (VS), 39.1% total carbon (TC), and 0.48% total nitrogen (TN).

The activated sludge used as inoculums for anaerobic digestion was obtained from a two-stage anaerobic digester in Liulitun Wastewater Treatment Plant, Beijing. It contained 10.2% TS, 5.48% VS, and 9.80% mixed liquor suspended solids (MLSS).

2.2 Ammonia pretreatment

Three ammonia doses, 2%, 4%, and 6%, and three moisture contents, 30%, 60%, and 80%, both of which are on dry basis of wheat straw, were applied for the pretreatment. In the process, water was added to ensure complete chemical reactions, but no extra water was left to avoid the pollution of waste ammonia solution. Moisture content (MC) of wheat straw is calculated as follows:

Certain amounts of ground wheat straw were prepared and added into plastic bags, and aqueous ammonia was added to make their concentrations in 2%, 4%, and 6% NH3, based on dry wheat straw. For each group, certain amount of water was added to make the moisture contents at 30%, 60%, or 80%. The materials were mixed thoroughly, sealed and placed quickly in an incubation chamber at constant temperature of (35±1) °C. The pretreatment time was determined by pH values. The pretreated wheat straws were used as feedstocks for the following anaerobic digestion experiments and chemical composition analyses.

2.3 Anaerobic digestion

The untreated and ammonia-pretreated wheat straws were digested in batch anaerobic digesters. The volume of each digester was 2 L, with a working volume of 1.5 L. Three loading rates, 50, 65, and 80 g·L−1, were applied. Certain amount of wheat straw was placed into each digester at certain loading rate, which is defined as the dry mass of wheat straw loaded (TS) per liter effective volume of digester (g·L−1), seeded with the activated sludge to maintain 15 g·L−1MLSS [5]. No extra nitrogen sources were needed in ammonia-pretreated wheat straw digestion systems. Additional water was added to each digester to maintain the same working volume of 1.5 L. The prepared digesters were placed in the shakers for anaerobic digestion tests at mesophilic temperature (35 °C) and a shaking speed of 150 r·min−1.

2.4 Analytical method

2.4.1 Biogas analysis

Daily biogas production for each digester was monitored by water displacement method, and the corresponding cumulative biogas volume was calculated. The methane content of the biogas was analyzed every day by a gas chromatography. The temperature of oven, injector port, and thermal conductivity detector (TCD) was 120, 150, and 150 °C, respectively. Hydrogen was used as the carrier gas at a flow rate of 30 ml·min−1. A standard gas with 5.0% N2, 60.1% CH4and 34.9% CO2was used for the calibration of the system.

2.4.2 Chemical composition analysis

TS and VS of the wheat straw, sludge and mixture in the digester were measured according to the APHA standard methods [16]. TC and TN were determined by the TC analyzer and the total Kjeldahl nitrogen analyzer. The pH value was tested by a pH meter. The contents of lignin, cellulose, and hemicellulose (LCH) were determined by the extraction unit for determining raw fiber content according to the procedures proposed by Van Soest et al [17]. The extractive contents of cold-water and hot-water were determined according to the standard methods [18].

3 RESULTS AND DISCUSSION

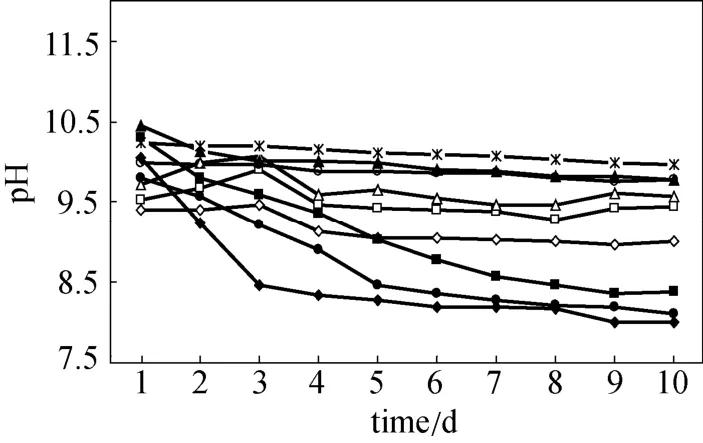

3.1 Determination of pretreatment time

The pretreatment time for ammonification was determined according to pH values. The changes of pH values of the wheat straws pretreated under nine conditions are shown in Fig. 1. Generally, pH values decrease in the first five days and then almost maintain constant. However, for different moisture contents and ammonia amounts, the change profiles are different. For the straws with higher doses of ammonia, the pH values drop more slowly than those with lower doses. It seems that higher moisture content helps the distribution and dissolution of ammonia, and enhances the chemical reaction processes. It is assumed that the ammonia reaction with the compositions of straw is complete and the pretreatment is ended when pH values become constant. For these pretreated straws, seven days are sufficient for ammonia pretreatment, which was used for later experiments.

Figure 1 Changes of pH values of wheat straws pretreated under different conditions

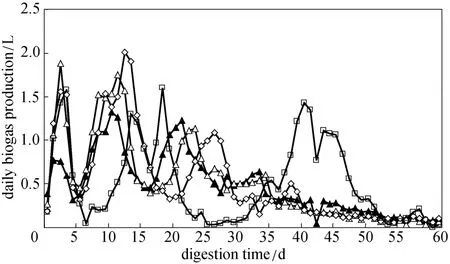

Figure 2 Daily biogas productions with untreated and ammonia-pretreated wheat straws at 30% MC▲ untreated; △ 2%NH3, 30%MC; ◇ 4%NH3, 30%MC; □ 6%NH3, 30%MC

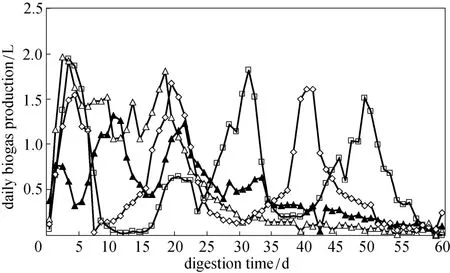

Figure 3 Daily biogas productions with untreated and ammonia-pretreated wheat straws at 60% MC▲ untreated; △ 2%NH3, 60%MC; ◇ 4%NH3, 60%MC; □ 6%NH3, 60%MC

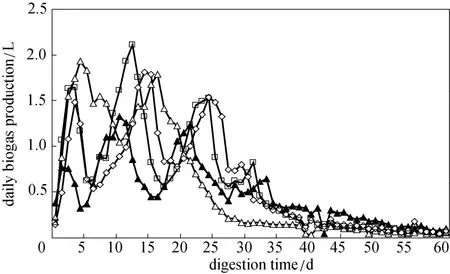

Figure 4 Daily biogas productions with untreated and ammonia-pretreated wheat straws at 80% MC▲ untreated; △ 2%NH3, 80%MC; ◇ 4%NH3, 80%MC; □ 6%NH3, 80%MC

3.2 Biogas production

Daily biogas production was measured and used to show the change profile of biogas generated during the whole digestion process. Daily biogas productions at the loading rate of 65 g·L−1were chosen to compare the effects of moisture contents and ammonia amounts (Figs. 2-4). There were 3-4 biogas production peaks at 30% moisture content (Fig. 2). The highest daily biogas production was 1750, 2010, and 1600 ml for 2%, 4%, and 6% ammonia-pretreated wheat straws, respectively, which were 33%, 52%, and 21% higher than that of untreated one. Similar trends could be found at 60% moisture content (Fig. 3), the last peaks ended at 51th and 57th day for wheat straws pretreated with 4% and 6% doses of ammonia, respectively. The trends of daily biogas production of ammoniapretreated wheat straws at 80% moisture content were apparently different (Fig. 4). Generally, the lasting time for biogas production with higher moisture content was shorter. There were 2-3 biogas peaks for daily biogas production (Fig. 4). The production ended 10 days earlier and no extra peaks occurred later. The highest daily biogas production were 1790,1810, and 2110 ml for 2%, 4%, and 6% ammoniapretreated wheat straws, respectively, which were 36%, 37%, and 60% higher than that of untreated one. Compared to the untreated wheat straw, ammoniapretreated wheat straws saturated in enough water generally gives better daily biogas production, with shorter digestion time.

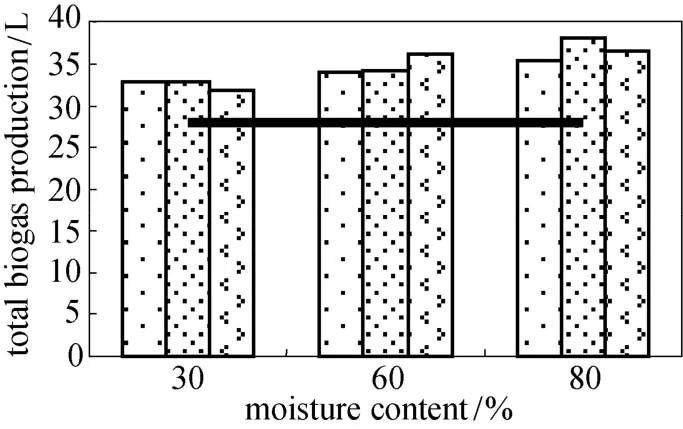

Total biogas productions (TBP) for untreated and ammonia-pretreated wheat straws at different loading rates are shown in Figs. 5-7. TBPs were all improved after ammonia pretreatment, but the improvement could differ at different moisture contents, ammonia doses, and loading rates. Generally, at lower moisture content, ammonia dose, and loading rate (30%, 2%, 50 g·L−1), the difference is less in TBPs between untreated and ammonia-pretreated wheat straws, while at higher moisture content, ammonia dose, and loading rate (80%, 6%, 80 g·L−1), the difference becomes significant. At the loading rate of 50 g·L−1, compared to untreated wheat straws, TBPs were increased by 1%-13%, 13%-15%, and 14%-29% at moisture contents 30%, 60%, and 80%, respectively. At the loading rate of 65 g·L−1, the TBPs of ammonia-pretreated straws were 13%-17%, 21%-29%, and 26%-36% higher, while at the loading rate of 80 g·L−1, the increase of TBPs reached 8%-22%, 24%-32%, and 23%-37%, respectively. These results indicate that sufficient water and ammonia will facilitate chemical reaction processes and enhance the effectiveness of pretreatment.

Figure 5 Total biogas productions of untreated and ammonia-pretreated wheat straws at the loading rate of 50 g·L−1

Figure 6 Total biogas productions of untreated and ammonia-pretreated wheat straws at the loading rate of 65 g·L−1

Figure 7 Total biogas productions of untreated and ammonia-pretreated wheat straws at the loading rate of 80 g·L−1

3.3 Daily methane content and methane yield

Daily methane contents (DMC) of untreated and 6% ammonia-pretreated wheat straw at three loading rates are shown in Fig. 8. The trends are the same for untreated and ammonia-pretreated wheat straws. DMC increases gradually after inoculation and maintained in certain range (50%-65%) as the process becomes stable. Acidogens dominate in the early stage and mainly convert biodegradable carbon elements to volatile fatty acids (VFAs) and carbon dioxide, while methanogens grow up and continuously convert VFAs to methane. The acidogens and methanogens finally reach a balance in the later stage, making the AD process stable and continue to generate biogas. The average methane contents in the whole processes did not show significant difference, which was within the ranges of 49.9%-52.9% for untreated and ammonia-pretreated wheat straws. It seems that pretreatment conditions affect biogas production obviously, but do not affect methane content. This may be related to complex chemical reactions in the pretreatment and biological activities in the anaerobic process. Further study is needed.

Figure 8 Daily methane contents at different loading rates

Methane yield, which is defined as the methane production per unit volatile solids loaded (ml·g−1), is used to compare the energy gain after ammonia pretreatment at 80% moisture content. Although the TBP at the loading rate of 80 g·L−1is higher, the methaneyield is obviously lower than that of 65 g·L−1(Fig. 9). This may be due to the existence of more ammonianitrogen, restraining the activity of anaerobic bacteria and reducing the biogasification efficiency. The wheat straw treated by 4% dose of ammonia and 80% moisture content and digested at the loading rate of 65 g·L−1achieved the highest methane yield of 199.7 ml·g−1. Therefore, these pretreatment parameters are considered appropriate, which gave a methane yield 36% higher than that of untreated one.

Figure 9 Methane yields of untreated and ammoniapretreated wheat straws at 80% moisture content

3.4 Technical digestion time

Technical digestion time (T80), defined as the time required for achieving 80% of maximum gas production, was calculated to compare the biodegradability of the straw from another indicator [19]. The maximum gas production was the total gas produced in the period of 60 days, after which little biogas was produced, so it was considered as the end of digestion (Table 1). T80has important economic significance, as less T80means shorter digestion time and higher conversion efficiency.

It was found that T80was affected by various parameters such as moisture contents, ammonia doses, and loading rates, and T80could significantly differ for different parameters. At lower loading rate of 50 g·L−1, ammonia-pretreated wheat straws required average T80of 22.8 days, very close to T80of 23 days with untreated straw. It indicated that the digestion time required did not show obvious difference at lower loading rate. At higher loading rate of 65 g·L−1, the wheat straw with 80% moisture content and 2%-6% ammonia pretreatment required less T80, 21-28 days, which is 5-11 days less than that with untreated one. At the highest loading rate in the experiment, 80 g·L−1, the straws with lower ammonia doses (2%) used less T80, 20-40 days, while those with higher ammonia doses (6%) used more T80, 48-49 days. This may be due to the existence of more soluble NH4-N, restraining the activity of anaerobic bacteria with more ammonia applied [20, 21]. As the wheat straw treated by 4% ammonia, 80% moisture content, and 65 g·L−1loading rate achieved the highest methane yield as mentioned in Section 3.3 and used less T80(25 days), the parameters are recommended for ammonia pretreatment for wheat straw.

3.5 Effects of C/N ratio and main compositions

The improvement of biodegradability and biogas yield are attributed to proper C/N ratio, enhanced buffering capacity, and decomposition of main compositions into relatively readily biodegradable substances in ammonia pretreatment.

The metabolism of anaerobic bacteria needs proper C/N ratio, providing carbon and nitrogen sources for bacteria growth. The C/N ratio of raw straw is 81.5, higher than the optimal range of 20-35 for anaerobic bacteria, so the C/N ratio for the ammonia-pretreated straws should be adjusted. The wheat straw treated by 4% ammonia and 80% moisture content maintains an optimal C/N ratio of 32 in the reactor. In addition, the straws pretreated by ammonia present higher buffering capacity and maintain stable operation in digestion systems, as remaining NH3after pretreatment is capable of neutralizing partial H+generated from acidification process in anaerobic digestion [21].

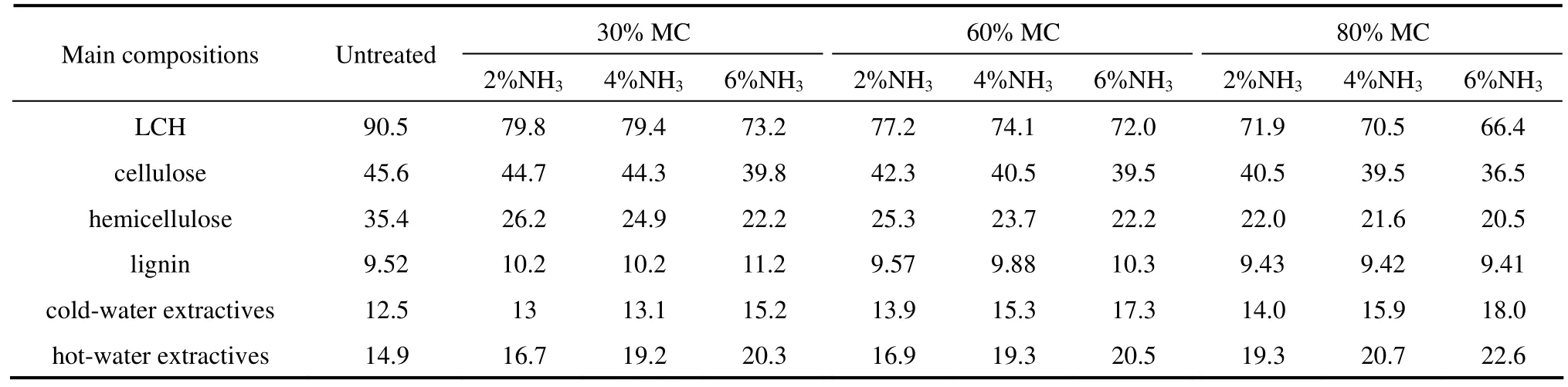

Lignin, cellulose, and hemicellulose (LCH) are the main compositions of wheat straw, providing main carbon sources for anaerobic microorganisms. Due to the chemical reaction of ammonia, the compositions will be changed during pretreatment, which influences the biodegradability of wheat straw and later anaerobic digestion processes. In this study, water-soluble components are also analyzed to investigate the changes of main compositions. The results are shown in Table 2.

Table 1 Comparison of T80for untreated and ammonia-pretreated wheat straws at different pretreatment parameters (day)

After ammonia pretreatment, the LCH was reduced by 12%-19%, 15%-21%, and 21%-27%, respectively, for wheat straws pretreated with 30%, 60%, and 80% moisture contents. It suggested that higher moisture contents could accelerate the effect of pretreatment and biodegradability of lignocelluloses. 2%-20% of cellulose and 26%-42% of hemicellulosewere decomposed for the pretreated wheat straws with different moisture contents, parts of which were converted into soluble components, which is believed to have positive effect on the degradability of cellulose [22, 23]. However, there was no obvious removal of lignin from pretreated wheat straws.

The cold-water and hot-water extracts are the materials extracted by cold and hot water. They are mostly consist of sugar, starch, pectin, tanning, cyclitol, and some inorganic substances [24], which are mainly from the decomposition of hemicellulose and partly from the decomposition of lignin and cellulose. Because of their biodegradability, more extracts will be beneficial for the enhancement of biogas production. The contents of cold-water and hot-water extracts increase with ammonia content, but the effect of ammonification is different at different moisture contents.

Compared to the untreated wheat straw, for the ammonia-pretreated wheat straws with moisture contents of 30%, 60%, and 80%, cold-water extracts was increased by 4%-22%, 11%-38%, and 12%-44%, and hot-water extracts was increased by 12%-36%, 13%-38%, and 30%-52%, respectively. It indicates that ammonia pretreatment is beneficial for decomposing wheat straw to some biodegradable soluble substances, especially at higher moisture contents, which provides “water-saturated” condition, producing more biodegradable substances and enhancing biogas production.

4 CONCLUSIONS

Ammonia pretreatment is proved to be an effective way to improve the biogas production of wheat straw. Ammonia pretreatment provides nitrogen for anaerobic digestion and reduces the cost of pretreatment. 80% moisture content, 4% dose of ammonia, and 7 day pretreatment at 35°C are recommended for wheat straw, which gave a methane yield of 199.7 ml·g−1(based on per unit volatile solids loaded) at the loading rate of 65 g·L−1in 25 days of digestion time. Cellulose, hemicellulose, and lignin were decomposed by 13%, 39%, and 1%, cold-water and hot-water extracts were increased by 27% and 39%, respectively, during pretreatment period. These changes of the main compositions and the appropriate C/N ratio are considered to be the main reasons for the improvement of biodegradability and the enhancement of methane yield.

Table 2 Changes of main compositions after ammonia pretreatment (%, dry matter)

REFERENCES

1 Renewable Energy Policy Network for the 21st Century, “Renewables 2010 Global Status Report”, www.REN21.net.

2 Cui, M., Zhao, L.X., Tian, Y.S., Meng, H.B., Sun, L.Y., Zhang, Y.L., Wang, F., and Li, B.F., “Analysis and evaluation on energy utilization of main crop straw resources in China”, Transaction of CASE, 24 (12), 291-296 (2008). (in Chinese)

3 Zheng, Y., Pan, Z.L., Zhang, R.H., El-Mashad, H.M., Pan, J., Jenkins, B.M., “Anaerobic digestion of saline creeping wild ryegrass for biogas production and pretreatment of particleboard material”, Biores. Technol., 100 (4), 1582-1588 (2009).

4 Romano, R.T., Zhang, R.H., Teter, S., McGarvey, J.A., “The effect of enzyme addition on anaerobic digestion of Jose Tall Wheat Grass”, Biores. Technol., 100 (20), 4564-4571 (2009).

5 Zhang, R.H., Zhang, Z.Q., “Biogasification of rice straw with an anaerobic-phased solids digestion system”, Biores. Technol., 68 (3), 235-245 (1999).

6 Chaudhry, A.S., “Rumen degradation in sacco in sheep of wheat straw treated with calcium oxide, sodium hydroxide and sodium hydroxide plus hydrogen peroxide”, Animal Feed Science and Technology, 83 (3/4), 313-323 (2000).

7 Oji, U.I., Etim, H.E., Okoye, F.C., “Effects of urea and aqueous ammonia treatment on the composition and nutritive value of maize residues”, Small Ruminant Research, 69 (1), 232-236 (2007).

8 Gao, P.F., Fan, D.D., Luo, Y.N., Ma, X.X., Ma, P., Hui, J.F., Zhu, C.H., “Efficient and comprehensive utilization of hemicellulose in the corn stover”, Chin. J. Chem. Eng., 17 (2), 350-354 (2009).

9 Su, D.H., Sun, J.S., Liu, P., Lü, Y.P., “Effects of different pretreatment modes on the enzymatic digestibility of corn leaf and corn stalk”, Chin. J. Chem. Eng., 14 (6), 796-801 (2006).

10 Yang, D.Y., Li, X.J., Gao, Z.J., Wang, Y.W., “Improving biogas production of corn stalk through chemical and biological pretreatment: a preliminary comparison study”, Transaction of the CSAE, 19 (5), 209-213 (2003).

11 Zheng, M.X., Li, X.J., Li, L.Q., Yang, X.J., He, Y.F., “Enhancing anaerobic biogasification of corn stover through wet state NaOH pretreatment”, Biores. Technol., 100 (21), 5140-5145 (2009).

12 Pang, Y.Z., Liu, Y.P., Li, X.J., Wang, K.S., Yuan, H.R., “Improving biodegradability and biogas production of corn stover through sodium hydroxide solid state pretreatment”, Energy & Fuels, 22 (4), 2761-2766 (2008).

13 Kim, T.H., Kim, J.S., Sunwoo, C., Lee, Y.Y., “Pretreatment of cornstover by aqueous ammonia”, Biores. Technol., 90 (1), 39-47 (2003).

14 Schneider, M., Flachowsky, G., “Studies on ammonia treatment of wheat straw: effects on level of ammonia, moisture content, treatment time and temperature on straw composition and degradation in the rumen of sheep”, Animal Feed Science and Technology, 29 (3/4), 251-264(1990).

15 Ma, S.Q., Yuan, H.R., Zhu, B.N., Liu, Y.P., Zou, D.X., Dang, F., Pang, Y.Z., Li, X.J., “Effects of ammoniation pretreatment on anaerobic digestion performance of rice straw”, Transaction of CASE, 27 (6), 294-299 (2011). (in Chinese)

16 APHA-AWWA-WEF, “Standard methods for the examination of water and wastewater”, 20th ed., American Public Health Association Washington, DC (1998).

17 Van Soest, P.J., Robertson, J.B., Lewis, B.A., “Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition”, Journal of Dairy Science, 74 (10), 3583-3597 (1991).

18 Liu, S.C., Analysis and Detection of Pulp and Paper, Chemical Industry Press, Beijing (2004). (in Chinese)

19 Palmowski, L.M., Müller, J.A., “Influence of the size reduction of organic waste on their anaerobic digestion”, Water Sci. Technol., 41 (3), 155-162 (2000).

20 Hafner, S.D., Bisoqni, J.J.Jr., “Modeling of ammonia speciation in anaerobic digesters”, Water Res., 43 (17), 4105-4114 (2009).

21 Hansen, K.H., Angelidaki, I., Ahring, B.K., “Anaerobic digestion of swine manure: inhibition by ammonia”, Water Res., 32 (1), 5-12 (1998).

22 Sewalt, V.J.H., Fontenot, J.P., Allen, V.G., Glasser, W.G., “Fiber composition and in vitro digestibility of corn stove fractions in response to ammonia treatment”, Journal of Agricultural and Food Chemistry, 44 (10), 3136-3142 (1996).

23 Hendriks, A.T.W.M., Zeeman, G., “Pretreatments to enhance the digestibility of lignocellulosic biomass”, Biores. Technol., 100 (1), 10-18 (2009).

24 He, Y.F., Pang, Y.Z., Li, X.J., Liu, Y.P., Li, R.P., Zheng, M.X., “Investigation on the changes of main compositions and extractives of rice straw pretreated with sodium hydroxide for biogas production”, Energy & Fuels, 23 (4), 2220-2224 (2009).

2012-08-23, accepted 2012-09-24.

* Supported by the National High Technology Research and Development Program of China (2008AA062401) and the China-US International Cooperation Project (2011DFA90800), the Ministry of Science and Technology, China.

** To whom correspondence should be addressed. E-mail: xjli@mail.buct.edu.cn

猜你喜欢

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Effect of Adsorbent Diameter on the Performance of Adsorption Refrigeration*

- Filtering Surface Water with a Polyurethane-based Hollow Fiber Membrane: Effects of Operating Pressure on Membrane Fouling*

- A Facile Route for Synthesis of LiFePO4/C Cathode Material with Nano-sized Primary Particles*

- High-Thermal Conductive Coating Used on Metal Heat Exchanger*

- Kinetics of Forward Extraction of Boric Acid from Salt Lake Brine by 2-Ethyl-1,3-hexanediol in Toluene Using Single Drop Technique*

- Soft Sensor Model Derived from Wiener Model Structure: Modeling and Identification*