Impact of IACS Harmonized CSR on Tankers

2014-07-18ZHENGWenqing郑文青WUJiameng吴嘉蒙Yinhua刘寅华GUJun

ZHENG Wen-qing (郑文青) WU Jia-meng(吴嘉蒙)LⅠU Yin-hua(刘寅华) GU Jun (顾 俊)

(Marine Design & Research Institute of China,Shanghai 200011,China)

Impact of IACS Harmonized CSR on Tankers

ZHENG Wen-qing (郑文青) WU Jia-meng(吴嘉蒙)LⅠU Yin-hua(刘寅华) GU Jun (顾 俊)

(Marine Design & Research Institute of China,Shanghai 200011,China)

The external draft of Harmonized Common Structural Rules (CSR-H) for Bulk Carriers and Oil Tankers has been released for external review. Based on a consistent methodology at the adoption of the current CSR, CSR-H aims to be in compliance with the IMO GBS where GBS functional requirements fall within the scope, and the safety level is equivalent to or higher than the current CSR criteria. In this paper, by consequence assessment on a 320k VLCC, a 163k Suezmax tanker, a 115k Aframax tanker, a 76k Panamax tanker and a 48k MR tanker, the results of the comparison on the structural scantlings to CSR, the evaluation on the increasing of steel weight and some critical technique issues are discussed.

CSR-H; CSR; consequence assessment; steel weight

Introduction

The current used Common Structural Rules (CSR) for bulk carriers (BC) and oil tankers (OT)[1-2]were developed separately and were based on different technical approaches. In order to be in compliance with the International Maritime Organization (IMO) Goal Based Standards (GBS), it spends nearly six(6) years for International Association of Classification Societies (IACS) to harmonize the current CSR based on a consistent methodology, where GBS functional requirements will be within the scope of the Harmonized Common Structural Rules (CSR-H)[3]. Up till now, the two periods of Industry Review have been finished.

For oil tankers, it seems that some rule requirements in CSR-H are similar to those in CSR-OT. But from the consequence assessments, it is found that there are still some impacts on tankers and some items to be modified or changed to enhance reliability and rationality of rule requirements.

In this paper, based on China Association of National Shipbuilding Industry (CANSI)’s investigations of a series of CSR tankers, incl. a 320k VLCC, a 163k Suezmax tanker, a 115k Aframax tanker (plane bulkhead), a 76k Panamax tanker and a 48k MR tanker, the following technical issues are discussed by comparing CSR-H (External release 1 Apr. 2013) and CSR-OT (July 2012), besides the increase of steel weight is compared between CSR-H and as built scantlings.

(1) Overview of the increase of scantlings and steel weights

(2) Rule minimum thickness requirement

(3) Setting of pressure relief valve

(4) FE analysis for midship cargo region

Table 1 Principal particulars

5) FE analysis for foremost cargo tank region

6) Ultimate buckling capacity for stiffeners

Table 1 lists the principal particulars of the referred tankers in this paper.

1 Technical Issues

1.1 Overview of the increase of scantlings and steel weights

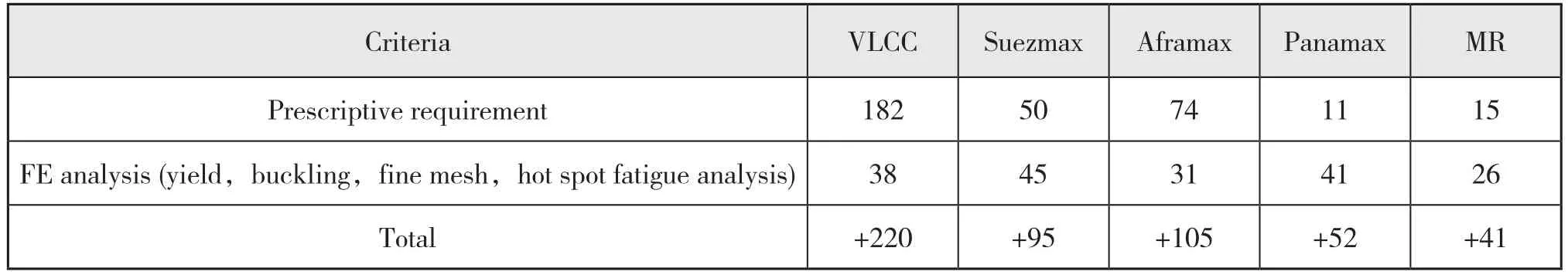

Table 2 lists the estimated results of structural steel weight increase within midship cargo region compared to CSR-OT.

The increasing of steel weight within mid cargo region is about 1%~2%. The increase due to prescriptive requirement is normally more than that due to FE analysis for tankers of VLCC, Suezmax and Aframax. For Panamax and MR, the increase for corrugated bulkhead due to FE buckling is prominent.

It should be pointed out that for any particular ship size a range of steel weight differences is possible since the estimates are highly dependent upon the degree of structural optimization and the original as-built design although all complied with CSR-OT.

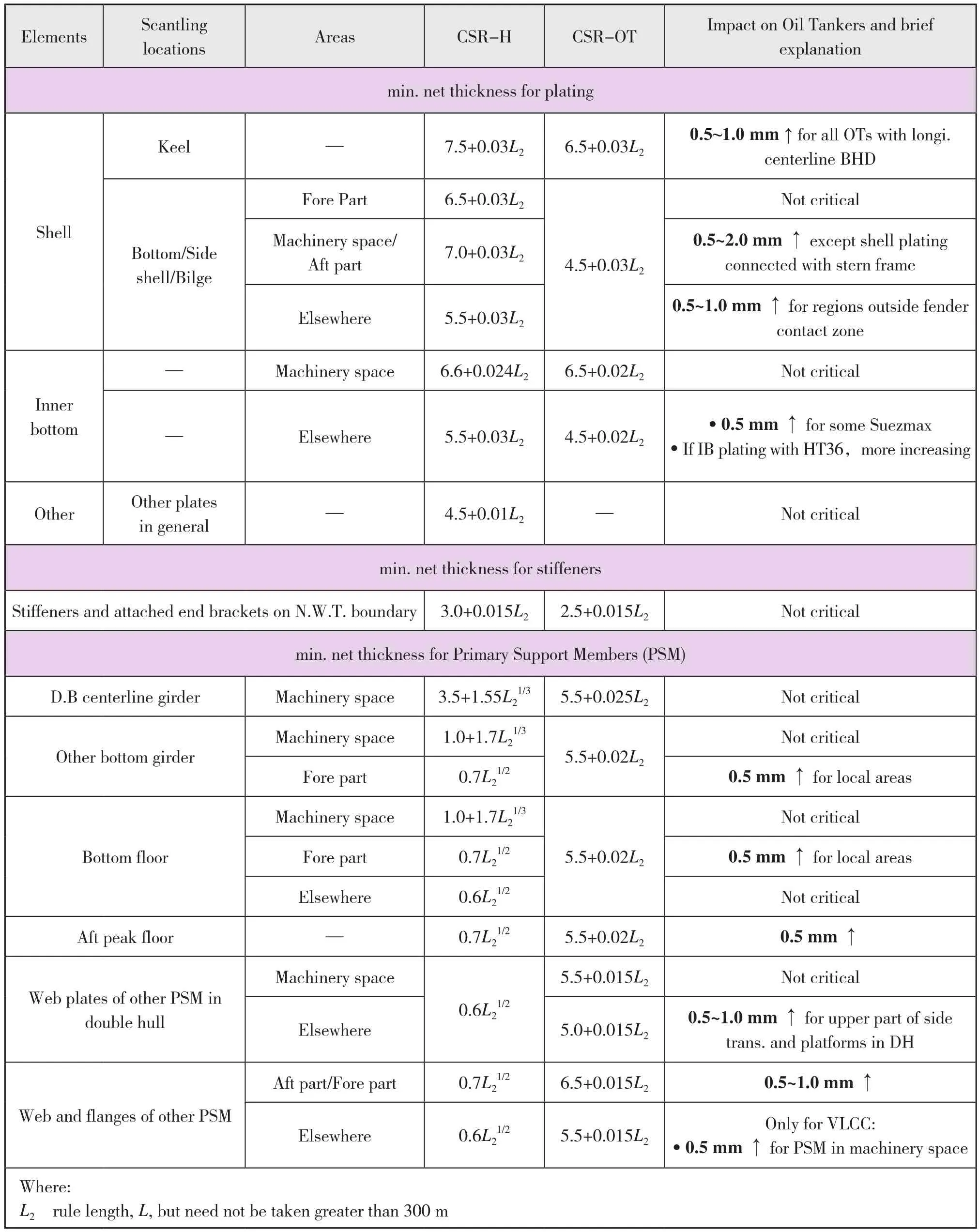

1.2 Rule min. thickness requirements

The following table gives the comparison between CSR-H and CSR-OT only due to Rule min. requirements, where the same requirements are omitted.

The impact on oil tankers and brief explanation is listed by our investigations for several oil tankers.

It could be found that for some regions, although higher Rule min. requirement by CSR-H, no critical impact for scantlings; while for other regions, the higher Rule min. requirement by CSR-H will increase the scantlings.

It should be noted that Rule min. requirement is the statistical data based on a lot vessels of same type.So for some parts, such statistical data or requirement for oil tankers or bulk carriers is not comparable e.g. web plates of PSM in double hull excluding girders or floors. If simply taking the envelop Rule min. requirement by CSR-OT and CSR-BC as that for CSR-H based on the basic principles for CSR maintenance and harmonization by IACS, it will increase some unnecessary steel weights.

Table 2 Steel weight increase within midship cargo region t

Table 3 Rule min. thickness requirement: comparison and impact

1.3 Issue on the load combinations in S+D conditions for oil cargo tank

For the design load scenarios in liquid cargo tanks, the difference between CSR-H and CSR-OT is as follows:

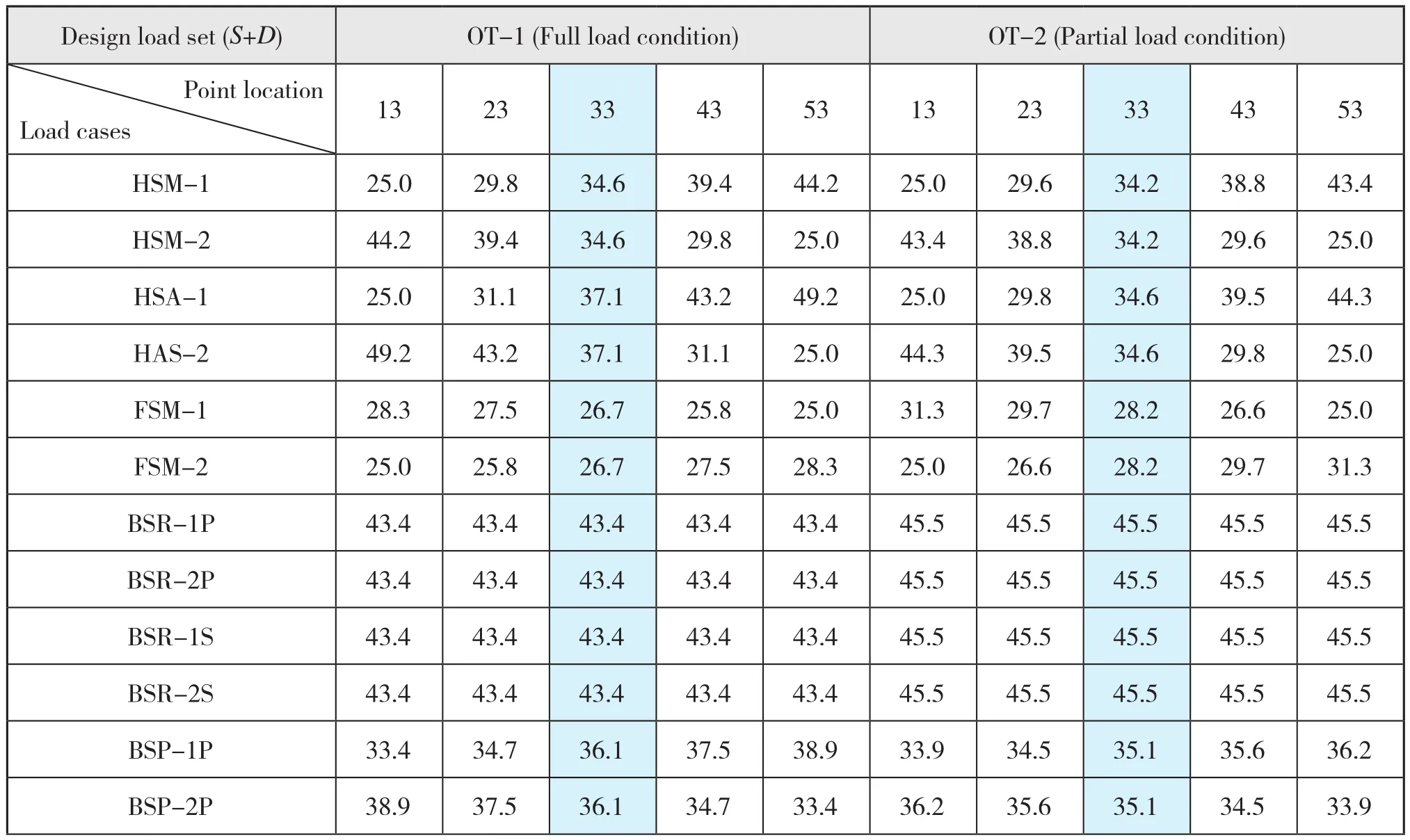

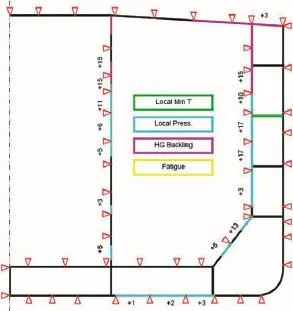

Table 4 Difference between CSR-H and CSR-OT for the design load scenarios in cargo tanks

It could be found that the vapour pressure (not to be less than Pvalveas required) is both considered in S and S+D condition in CSR-H and CSR-OT. The only difference is that in S+D condition of CSR-OT, 25 kN/m2is deducted; while in CSR-H, no deduction is made.

Pvalveis the setting of pressure relief valve, which is in general located at the midpoint of the highest level of cargo tank. During voyage (S+D condition), if the pressure near the valve is higher than the setting value of Pvalve(not less than 25 kN/m2), such valve will be opened automatically and the pressure will be decreased; when the pressure is lower than the closing pressure, such valve will be closed automatically. At the same time, such valve will ensure the cargo tank be not a vacuum space.

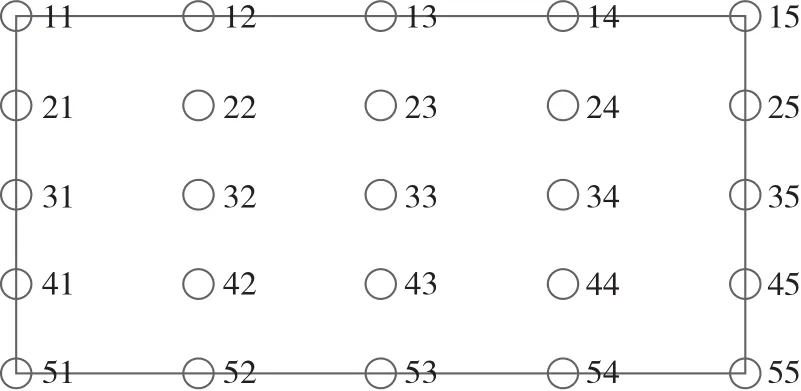

We carry out a testing calculation of the pressure distribution of a typical center COT (Crude Oil Tank) of a VLCC to investigate whether the cargo oil pressure value of the pressure relief valve is higher than its setting value (25 kN/m2). The calculation is to meet the requirement of CSR-OT and CSR-H respectively. The following tables list the results of midpoints ofthe highest level of the COT. In such points, No.33 is where the setting valve would probably be located.

Fig.1 Point location in the highest level of a typical center COT of a VLCC

Table 5 Cargo oil pressure distribution in S+D condition applied for CSR-OT

It could be found that for CSR-OT, the pressures at Point No.33 are all below 25 kN/m2; while for CSR-H, the pressures are all above 25 kN/m2. If the setting valve is located at Point No.33, the pressures in all load cases are not to be higher than 25 kN/m2.

Also, it could be found in the calculation of scantling requirements: for CSR-OT, S condition will be dominant for some plates or stiffeners on the boundaries of COT due to design load set No.4; while for CSR-H, the dominant load sets for the boundaries of COT are only from S+D condition, i.e. OT-1 or OT-2, but no S condition due to OT-3. The reason for such phenomenon is that the pressure in S+D condition is too higher than that in S condition.

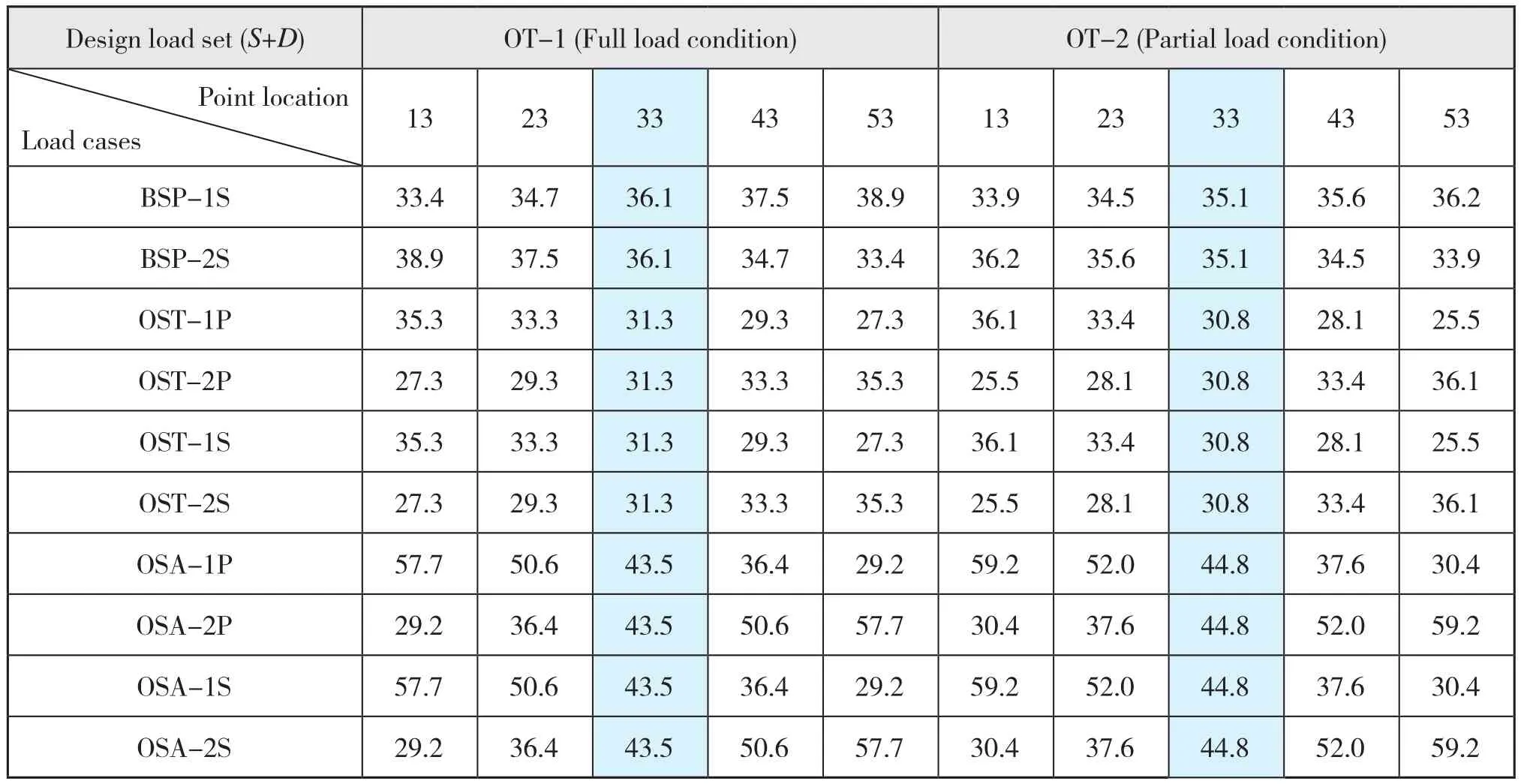

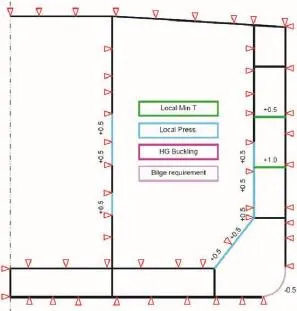

From the Consequence Analysis (CA) reports, it could be also found that for oil tankers, the scantlings ofsome plates or stiffeners on the boundaries of COT or some PSMs (Primary Supporting Members) in the COTs are to be increased due to local oil pressure. In Figure 2 and 3, the consequence assessment of a 320k_VLCC by CANSI is shown as an example, with the comparison between CSR-H requirement and the As-built scantling.

Table 6 Cargo oil pressure distribution in S+D condition applied for CSR-H

(续上表)

Fig.2 Plate thickness comparison between CSR-H and As-built scantling (320k_VLCC)

We think that the design load combinations for CSR-H in S+D condition are not suitable. The deduction in S+D condition is suggested to be considered to ensure the pressures in all load cases near setting valves no higher than their setting value. Such increase for cargo oil pressures in S+D condition willimpact the scantlings due to prescriptive requirement, FE yield strength and FE buckling strength.

Fig.3 Sectional Modulus comparison between CSR-H and As-built scantling (320k_VLCC)

1.4 FE analysis for midship cargo region

1.4.1 Load combinations for FE analysis

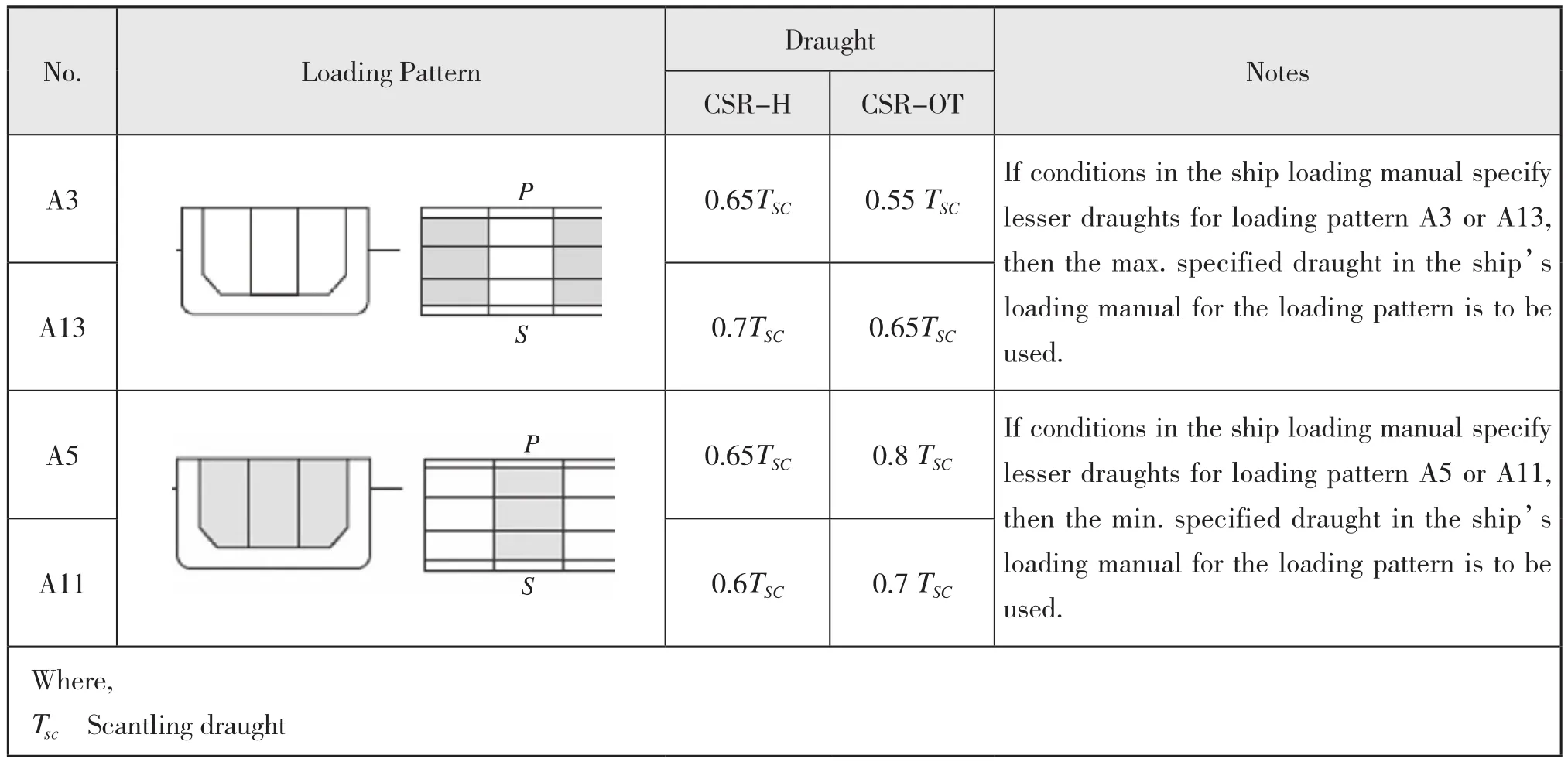

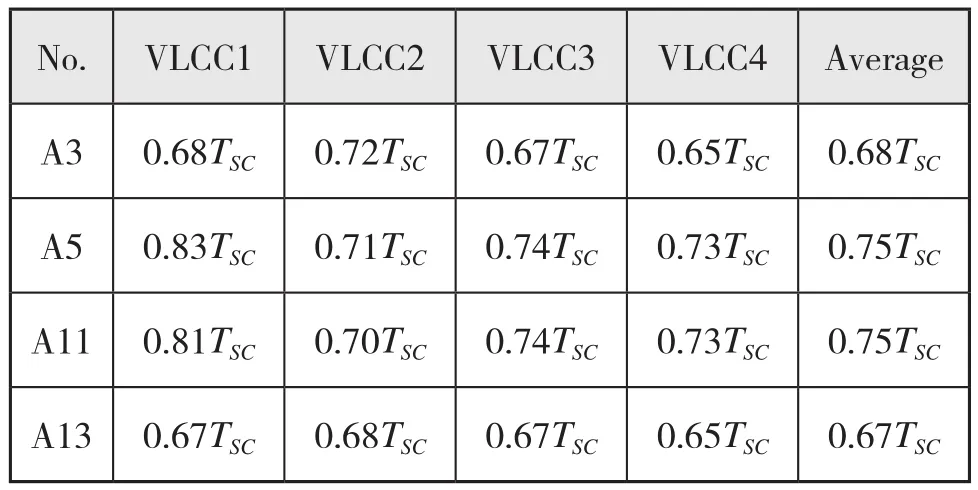

Comparing the load combinations for FE analysis between CSR-H and CSR-OT in Table 7, it is found the main difference is for the draughts in loading pattern A3, A5, A11 and A13 for tankers with two oil-tight bulkheads, e.g. VLCC, except for the new dynamic load cases.

For VLCC, cargo oil tanks abreast empty and the neighbor cargo tanks full does not exist. But if specifying A3, A5, A11 and A13 loading conditions in loading manual for existing VLCCs, the draught in corresponding loading condition is limited by the design envelop of SWBM (Still Water Bending Moment) and SWSF (Still Water Shear Force). The following is the statistics for the draughts of Chinese VLCCs in such non-typical loading conditions:

It could be found that the draughts in A3 and A13 will be close to that required by CSR-H; while the draughts in A5 and A11 will be close to that required by CSR-OT.1.4.2 Acceptance yielding criteria for FE analysis

Table 7 Comparison for the load patterns for FE analysis between CSR-H and CSR-OT

Table 8 Draughts of VLCCs in A3/A5/A11/A13 loading conditions

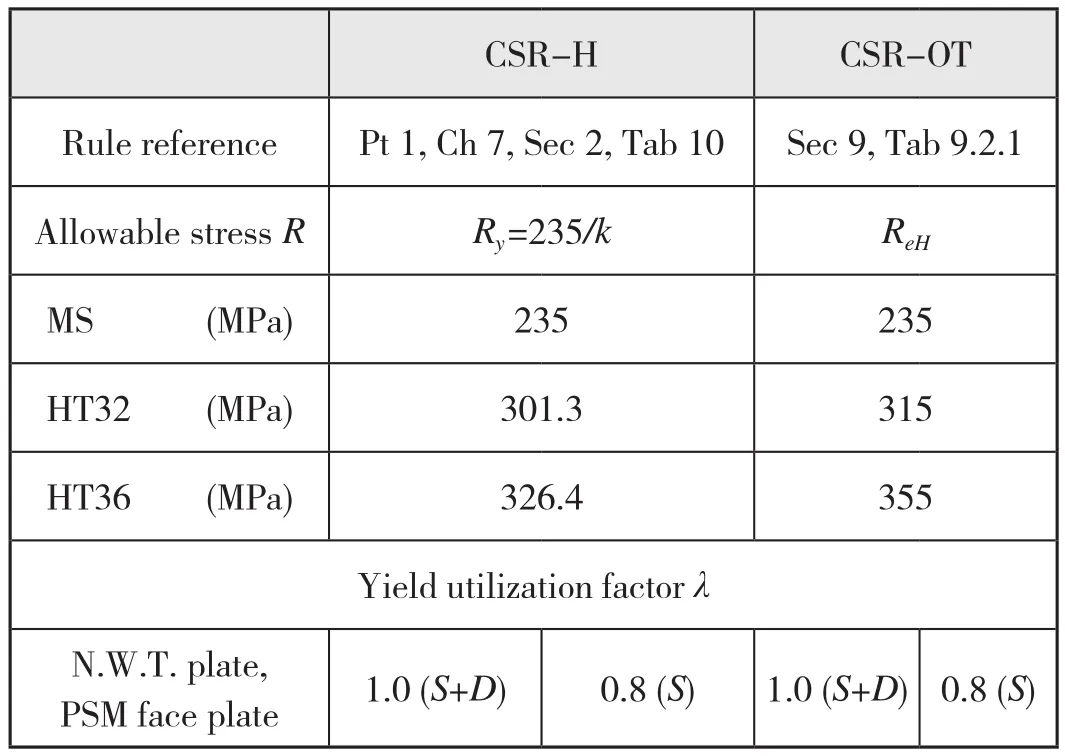

For the acceptable yielding criteria for N.W.T. (Non Watertight) plating and face plate of PSM in coarse mesh FE analysis required by CSR-H and CSROT, the comparison is shown in Table 9.

The acceptable criteria (λ·R) for N.W.T. structural members in CSR-H is higher than that in CSR-OT (for HT32 steel 4.6% criteria increased; for HT36 steel 8.8% criteria increased). At the same time, the cargooil pressure in S+D condition for CSR-H is higher than that required for CSR-OT. Both factors will induce steel weight increase for N.W.T. plating and face plate of PSM in oil tankers with high tensile steel used.

1.5 FE analysis for foremost cargo region

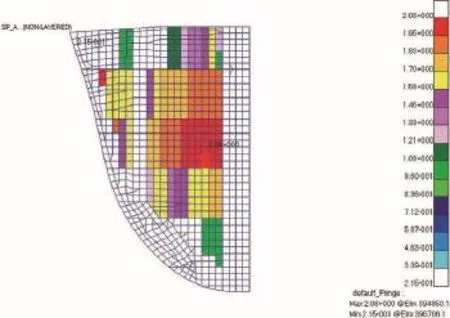

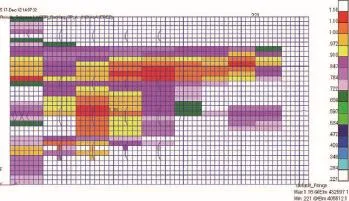

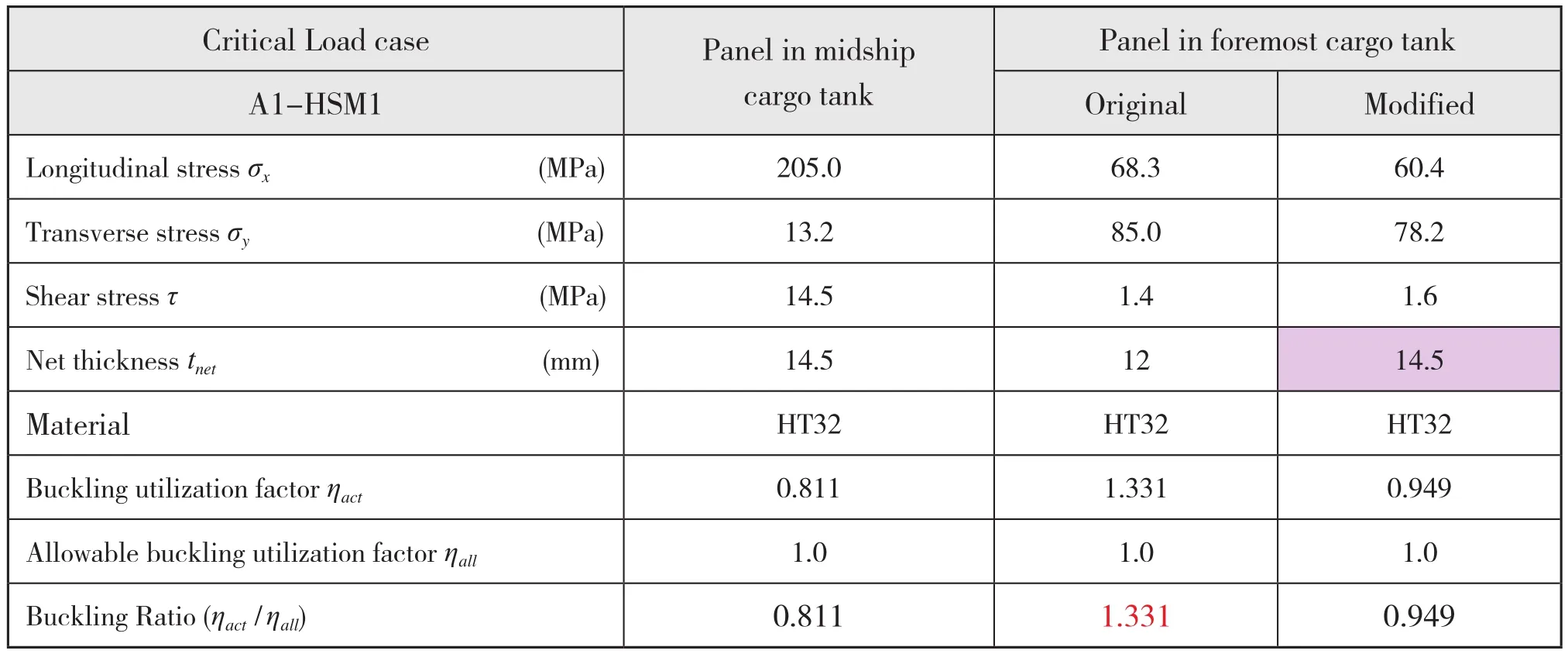

The strength analysis of a foremost cargo region of a typical 320k VLCC is carried out. It is found that FE buckling is a big problem for upper deck plating, inner hull longitudinal bulkhead plating and collision bulkhead plating as shown in Figure 4 to Figure 7.

Table 9 Comparison for the allowable criteria for FE analysis between CSR-H and CSR-OT

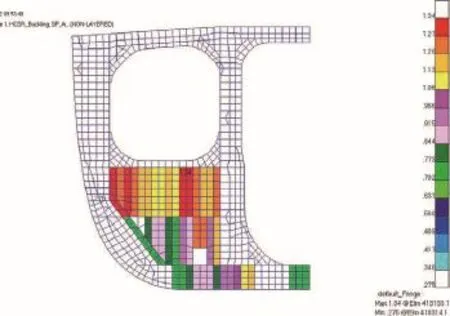

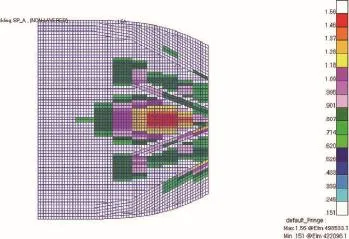

Fig. 4 Buckling utilization factor for the collision BHD

Fig. 5 Buckling utilization factor for the Swash BHD in foremost COT

Fig. 6 Buckling utilization factor for upper deck

Fig. 7 Buckling utilization factor for Longi. BHD

Table 10 Comparison for buckling results for foremost cargo tank and midship cargo tank

It could be found that for the plate panels with same transverse and vertical location for upper deck, the value of sy(transverse stress) in foremost cargo region is increased much more than that in midship cargo region due to the increased green sea load. For modification, it could meet the buckling criteria by CSR-H when the plate thickness in foremost cargo area is to be same as that in midship cargo area or lots of buckling stiffeners are to be arranged. For other areas in foremost or aftmost cargo region, the same phenomena would occur for the buckling evaluation. That is to say, the increased external or internal loads will induce buckling issues for the foremost and aftmost cargo area, which should be paid more attention to.

The results above are based on external release April 2013. There are some modifications for external loads in foremost and aftmost cargo area, and the calculation results will be updated according to the latest release of rule. However, the tendency of the phenomena will not be changed.

1.6 Issue on the ultimate buckling capacity for stiffeners

The ultimate buckling capacity for stiffeners is required considering interactive lateral and warping (torsional induced) buckling modes.

In order to obtain the actual axial stress on the stiffener due to effective width of attached plate, the following formula is introduced with an increasing factor for nominal axial stress: σa=Fσx

where:

σx: Nominal axial stress, in N/mm2.

s: Spacing of stiffeners, in mm.

2017年5月—2018年5月,共搜集50例病例,均为我院临床诊断为ITN患者,其中男23例,女27例,年龄28~78岁,平均(55.8±10.6)岁。症状均为单侧,右侧30例,左侧20例。将有症状侧设为患侧组,无症状侧设为健侧组,各50侧。所有患者均符合国际头痛协会(IHS)制定的ITN诊断标准[2],检查前所有受试者均签署知情同意书。

tp: Net thickness of plate panel, in mm.

As: Net sectional area of the stiffener without attached plating, in mm2.

beff1: Effective width of the attached plating of stiffener, in mm, without the shear lag effect.

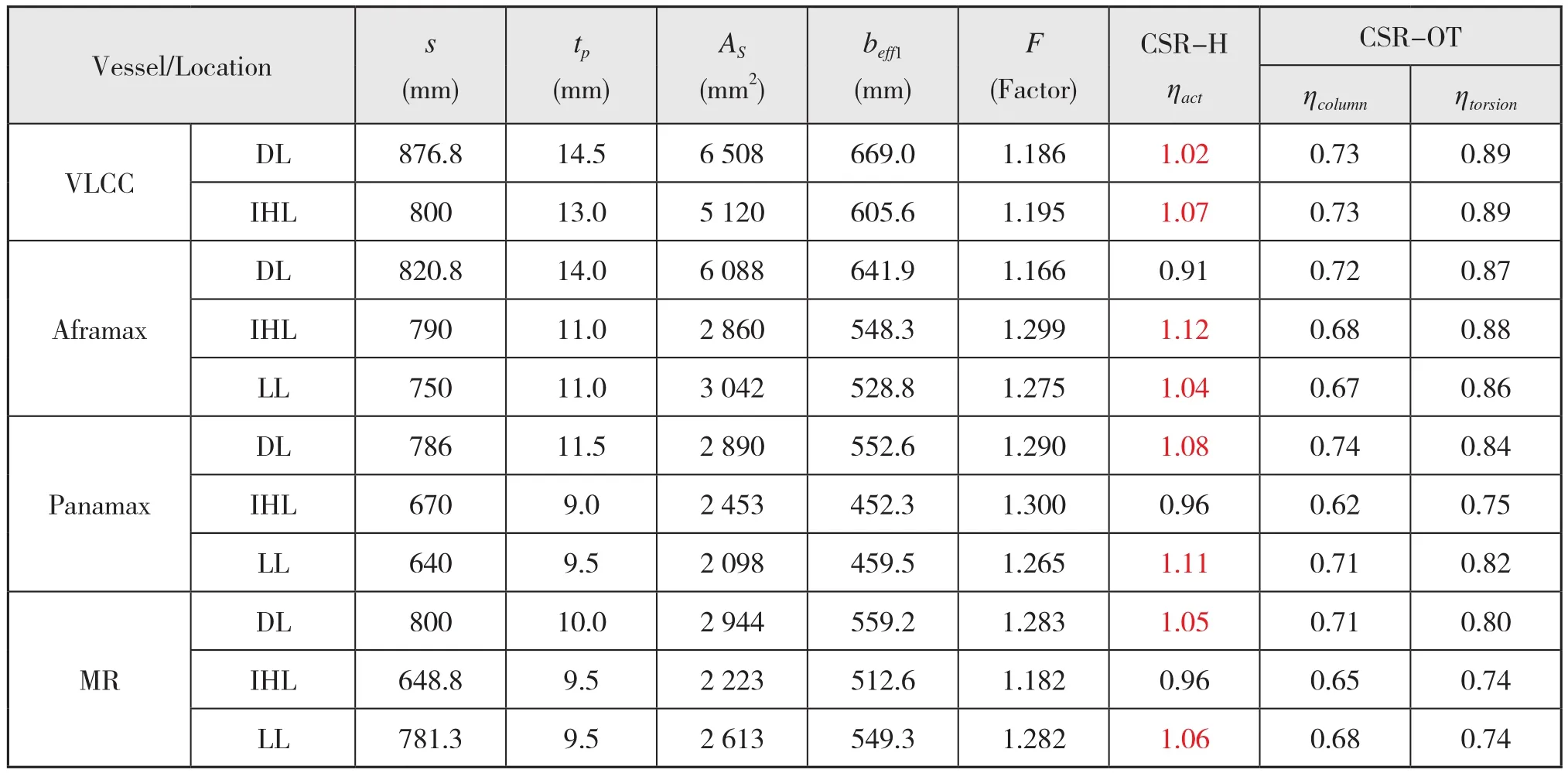

But as CSR required, σa=σx, no considering foran increasing factor. By the statistics for series of oil tankers, it is found that the increase for the effective axial stress is a bit larger (15%~30%) due to such factor as shown in Table 11.

The increase of axial stress has negative effect on the longitudinals with little margin for the buckling utilization factor, which will lead to the fact that the prescriptive buckling results cannot meet the CSR-H requirement for the longitudinals in the main deck and 0.1D below for most tankers, shown in figure 3 for 320k_VLCC as a example.

Table 11 Increasing factor for nominal axial stress to effective axial stress

2 Estimation of design period

It could be found that the design, verification and approval period of CSR-H will be a big increase compared to the current CSR due to the following requirement:

For coarse mesh FE analysis, it is required to cover the whole cargo area by CSR-H, not only for midship cargo area same as that required by CSR, but also for the foremost and aftmost cargo area.

For fine mesh FE analysis, the mandatory structural details is added by CSR-H, especially for the bulk carriers, and the screening areas are increased by CSR-H, especially for the outside midship cargo hold regions.

For fatigue analysis, list of details for mandatory very fine mesh analysis is increased, and additional design requirements by design standard are added: if not compliance with such standards, very fine mesh analysis is required. And fatigue screening procedures of less critical details are introduced.

Not only for prescriptive requirement but also for FE and fatigue analysis, loading patterns by CSR-H are increased.

By conservative estimation for the modeling and FE analysis for the foremost and aftmost cargo areas, at least 1.5 times more than that for the midship cargo area is required, respectively. If no efficient FEmodeling tools, more time will be possible. Therefore, the design, verification and approval period will be estimated about 3~5 times more than that for CSR.

3 Conclusion

CSR-H has been reviewed by industry for 2 periods. Some requirements or contents have been revised based on the comments from industry. But so far, there are still some issues, some of them are listed in this paper, which are to be discussed and considered by IACS.

By our consequence assessment for a serial of CSR tankers, the impact of CSR-H on tankers can be summarized as following:

(1) The increase by prescriptive requirement is normally more than that by FE analysis for VLCC, Suezmax and Aframax with plane bulkhead. For Panamax and MR, the increase for corrugated bulkhead due to FE buckling is prominent.

(2) The total increase of steel weight in midship cargo area is about 1%~2%.

(3) The design, verification and approval period will be about 3~5 times more than that for CSR.

[1] Common Structural Rules for Double Hull Oil Tankers[S]. 2012, 7.

[2] Common Structural Rules for Bulk Carriers[S]. 2012, 7.

[3] Common Structural Rules for Bulk Carriers and Oil Tankers[S]. Technical Committee Release, 2013, 11.

[4] Common Structural Rules for Bulk Carriers and Oil Tankers Technical Background Rule Reference[S]. Technical Committee Release, 2013, 11.

[5] WU J M. Influences of common structural rules on the structural design of very large crude oil carrier[J]. Ship Engineering, 2007, 29(4):13-16.

U692.7

A

1001-9855(2014)01-0106-11

工信部十二五高技术船舶科研项目——基于目标型标准的共同结构规范关键技术研究(2012K24251)。

2014-01-03

郑文青(1986-),男,上海交通大学硕士,工程师。

吴嘉蒙(1976-),男,上海交通大学硕士,高级工程师。