The Design and Implementation of Black Tea Traceability System Based on UHF RFID

2014-04-10CaijinLINGJinxinLIUJiayaoWUQiushuangWANGShumeiLIUHaiqiangCHENChaoyiZHAO

Caijin LING,Jinxin LIU,Jiayao WU,Qiushuang WANG,Shumei LIU,Haiqiang,CHEN,Chaoyi ZHAO

Drinkable Plants Institute,Guangdong Academy of Agricultural Sciences/Guangdong Provincial Key Laboratory of Tea Plant Resources Innovation and Utilization,Guangzhou 510640,China

Since the promulgation of Operating Rules for Quality and Safety Traceability of Agricultural Products-Tea(NY/T 1763-2009)by the Ministry of Agriculture in April 2009,the operation of quality and safety traceability of the tea industry has been standardized.In recent years,some scholars have used the means of barcode+platform,geographical indications and commodity barcode for green tea,white tea,Longjing tea,Pu'er tea,etc.,to establish the traceability management system and try to popularize the traceability system,in order to provide a systematic and reliable technology system for the process from tea garden to tea cup[1-4].

In addition,there are scholars using barcode or isotopic fingerprint traceability technology,near-infrared spectroscopy,X-ray fluorescence technology and thermal analysis technology,etc.[5-12]for the traceability of tea,but due to the long production cycle of tea,scattered producing areas and other factors,it is difficult to promote,and its application in production processes is greatly restricted,becoming the largest technological bottleneck to tea production information flow.With no need of the network or online database support,the labels with storage capacity used by the radio frequency identification(RFID)technology can record the traceability information in the production chain,and it has a unique identification number(ID).

Yinghong 9 is a fine provincial variety of tea examined and determined by Guangdong Academy of Agricultural Sciences in 1988[13].After years of breeding and development,Yinghong 9 is not only a name of variety of tea,but also a name of commodity.Yingde black tea,a specialty tea in Guangdong Province,was identified as geographical indication protection product in 2007[14].

Yingde black tea is famous both at home and abroad for its shape,color,smell and taste,and Yinghong 9 as the representative of Yingde black tea stirs the consumption interest in black tea across South China and Hong Kong and Macao.

However,since Yingde black tea is very popular on the market,there is an endless stream of fake and shoddy products,seriously affecting the quality and reputation of Yingde black tea.In the context of growing consumer awareness of food safety and the formal implementation of Food Safety Law in June 2009[15],Drinkable Plants Institute of Guangdong Academy of Agricultural Sciences takes Yinghong9 black tea as the experimental sample to carry out the study of the black tea traceability system based on UHF RFID,with the purpose of improving the quality and safety management of Yingde black tea.

1 Data collection and identification for the production of Yinghong 9 black tea

The production of Yinghong 9 involves the basic conditions of water,air and soil in the cultivation base,the agricultural activities of weeding and fertilizing,and the production activities of picking,fresh leaves acceptance,processing,loading and unloading.The tracing process is also the whole process of production.

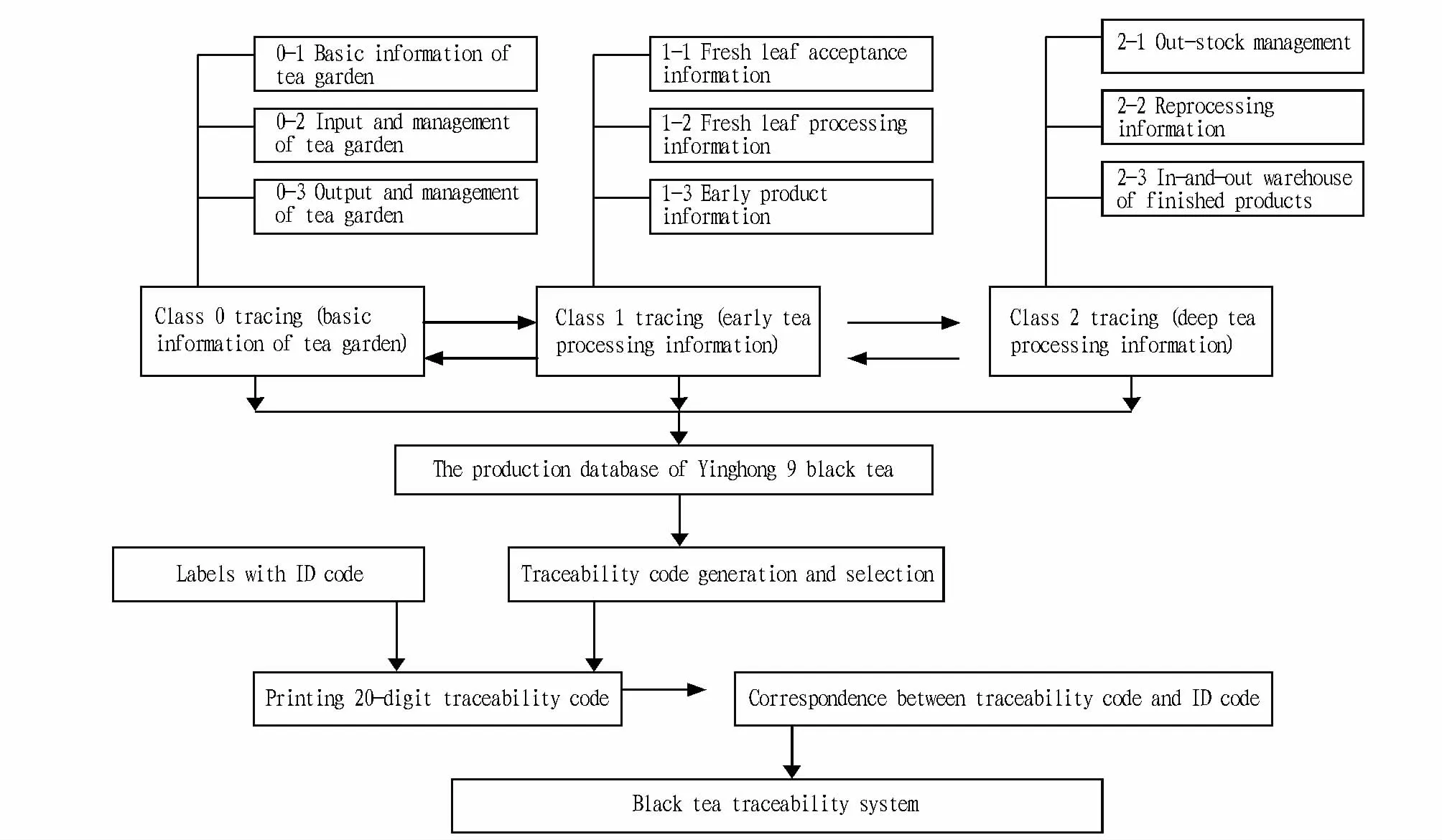

So,we design the three-class traceability system of Yinghong 9 black tea,namely Class 0,Class 1 and Class 2,respectively.The specific tracing process is as follows:

1.1 The basic content of Class 0 tracing

1.1.1 Monitoring information of tea garden.It mainly includes the basic information of location of tea garden,area of tea garden,tea varieties,soil quality of tea garden,air and water environment,water quality,altitude,and tea production period.It also includes the regular records of soil monitoring,air monitoring,and water monitoring.

1.1.2 Input to tea garden and field management information.The recorded inputs into the tea garden are divided into two categories:one is the fertility and soil improvement substance;the other is the protection product(including plant and animal sources,mineral sources,microorganism sources,other preparations,traps and isolation barriers).

The following items are recorded during every input:date,batch of input goods,use amount,use standards,use methods and use personnel.

The field management activities include pruning,weeding,scarification,irrigation and closing garden.The date,standards,specifications and results of daily field production management activities are recorded in detail.

1.1.3 Fresh leaf picking information.The date,quantity,grade,moisture content,price,responsible personnel and other information concerning the fresh tea picking are recorded.The mode of transport,transport staff,storage methods and other information are recorded.

1.2 The basic content of Class 1 tracing

1.2.1 Fresh leaves acceptance before their entrance to factory.The recorded fresh leaves acceptance information includes date,grade,quantity,weigh man and acceptance results.

1.2.2 Semifinished tea processing information.All the processes before the fresh leaves enter into the warehouses are recorded,including withering,rolling,deblocking,fermentation and drying.The information of completion time,completion status,operational staff,and the responsible person concerning each semifinished tea processing step is recorded.

1.2.3 The entry of semifinished tea into warehouses.The acceptance information of semifinished tea(early product)is recorded,such as the number,weighman,acceptance officers and acceptance results.

1.3 The basic content of Class 2 tracing

1.3.1 Out-stock management of semifinished tea.The information of out-stock management of semifinished tea(early product)is recorded,such as the number,weigh man,handlers and use.

1.3.2 Reprocessing information.The process information from the delivery of semifinished tea out of warehouses to the entry of finished product into warehouses is recorded,including separation,screening,blending,stacking and drying.The information of completion time,completion status,operational staff,and the responsible person concerning each processing step is recorded.

1.3.3 In-and-out warehouse information of finished tea.The acceptance information concerning the semifinished tea(early product)is recorded,such as quantity,grade,weighman,acceptance staff and acceptance results.

The test results of ach batch of finished tea are recorded,including sampling base,sampling number,retained samples,sampling number,shape,and end oplasm.The net content,powder and water content are recorded.

1.4 Batch of finished productsThe batch number is automatic ally generated,and the information of each batch is recorded,such as start date,end date,product name and expiration date.

1.5 The generation and identification of traceable code

According to the inputted minimum package number,the system automatically generates the same number of 20-digit traceable code.Through the traceable code,the batch number selected by the console is printed,and by entering the number to be printed,the RFID label printing documents are generated,and the traceable code is printed to the label.

The system writes the 20-digit tracing number corresponding to each label into the user data area of label,and at the same time,reads the ID code of the label chip,and returns the corresponding identification code and traceable code to the server's database.

2 The design and implementation of software system

According to the actual production and the requirements of Operating Rules for Quality and Safety Traceability of Agricultural Products-Tea(NY/T 1763-2009),the RFID technology is used to design the ultimate security mechanism for the tea products,the traceable code which cons is ts of20-digit random numbers is generated,and the query is conducted via the Internet.

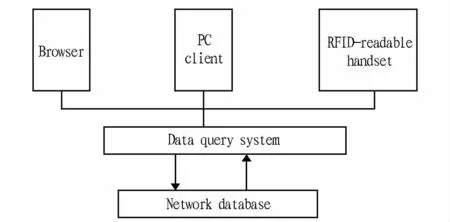

The overall design of the system is shown in Fig.1,and the structure of system end user is shown in Fig.2.

2.1 Technical featuresThe traceability system network of black tea uses.NET technology,Microsoft Visual Studio 2010+VB.NET,Microsoft SQLSERVER 2005,and T-sQL language development design,to store the collected information in the network data management center of safety traceability system.Using the technological mode of combining client/server(C/S)and browser/server(B/S),we can realize the functions of data collection,tracing,sharing and query.

When printing the traceable code label,the anti-counterfeiting function of tea products is realized by printing the traceable code onto the label,writing the traceable code into the EPC area of RFID label,reading and returning the label ID of RFID to form one-to-one correspondence to traceable code,and importing the returned traceable code-label ID into the system database.Only when the productshave both traceable code and TID label can they become non-counterfeit products.

2.2 Module com position

2.2.1 Data collection module.The information collection content includes tea garden monitoring information,tea garden input information,field management information,fresh leaf picking information,fresh leaf transport information,fresh leaf acceptance,semifinished tea processing information,finished tea processing information,finished tea testing,and finished product batch.

2.2.2 Tracking and tracing module.The tracing modules in-clude tracing part of raw material base of black tea,tracing part of tea processing and storage,tracing part of tea sales,etc.

Fig.1 The overall design structure of traceability system

Fig.2 The structure of system end-users

2.2.3 Traceability code management module.(i)The generation of traceable code.This function is to generate the same number of 20-digit traceable code for each valid batch,according to the inputted minimum package number.

(ii)The printing of tracing label.Through the traceable code,the batch number selected by the console is printed.The users can choose the printing batch,and enter the number to be printed,to generate the RFID label printing documents.

(iii)The tracing log query.Each traceable code query of the customers buying productswill be recorded and saved.

(iv)The operating module of RFID handset.Handset can be remotely connected to the system database via GPRSor WIFI,for the tea information query.

2.2.4 Traceable code query module.After the consumers buy the tea products,the purchased product information query can be completed by entering the query website on the label,and inputting 20-digit traceable code.

2.2.5 Code management module.The company,department,group,staff,land,raw materials,equipment,product category,product type and warehouses are encoded.

2.2.6 User setting module.The system provides multi-module,multi-user role design,so the requirements on access control are high.In the system,a series of access control measures are adopted.The browsing and editing authorization is set for the related menu functions concerning data collection.

The administrators of different roles have different management authorization,and they can manage different modules of the system database software,and perform the operations of viewing,adding,modifying and deleting the data of database corresponding to different modules.

If the user has no authorization on browsing and editing function module,he will not be able to run the menu functions,and even view this function module in the menu.If there is no editing authorization but browsing authorization,then it can not be modified but viewed.

2.2.7 The system management module.The system management module is divided into database backup,database recovery,access logs,help and other modules.

2.3 The implementation of systemThe system uses the design mode of combining C/S and B/S.The database and WEB program are in the server,and the traceable code query is open to the public.As to the internal relevant management and data collection,each 20-digit tracing number corresponds to the ID code of the label,and points to the corresponding batch and product type.

This system software adopts the network mode of B/S structure for the tea traceability in the tea garden,processing and packaging plant.WEB browser is the most important client software,and the printing of RFID traceable code uses the C/S structure.This three-tier structure of development makes the data and business processing concentrated in the server,simplifying the development,use and maintenance of the system,so it is easy to expand the system.

3 Data transmission

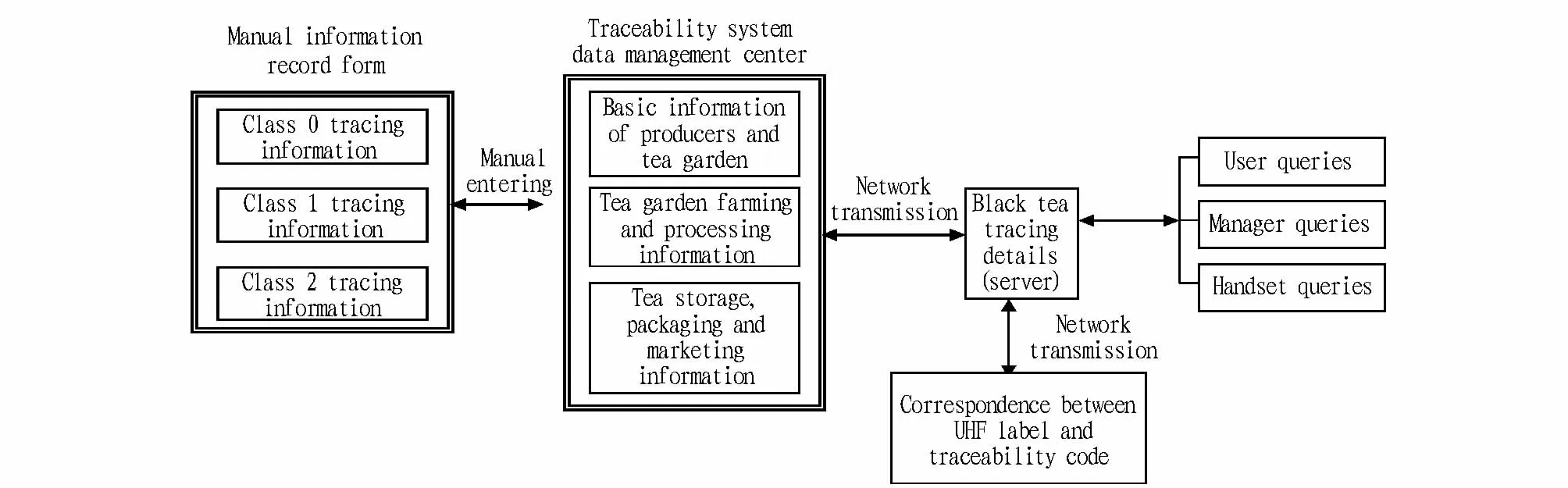

The Class0,Class 1 and Class 2 tracing information is saved in the network database of black tea tracing data center using the manual entry way.The label has ID,and at the time of printing,the system makes the ID correspond to traceable code and store them in the database.The traceable code and ID are read using RFID handset,and they are compared with the data in the database to identify the authenticity of the product.

The data transmission process is shown in Fig.3.

Fig.3 Data transmission process

4 Conclusions and discussions

The UHF RFID technology can be used to track and trace the whole process of black tea production.The research group applied this technology to the tea variety Yinghong 9 cultivated by Hongyan Tea Research and Development Center of Guangdong Academy of Agricultural Sciences,and significant economic and social benefits were obtained in the course of the demonstration and application.

(i)Based on the basic information,farming activities,fresh leaf picking,processing,quality testing,storage and other factors related to the quality and safety of black tea in Ying hong9 tea garden,the traceability system is to track and trace each production link of Yinghong 9(including various technical parameters and climatic conditions during the processing).Government regulators,consumers and producers can conduct query and tracing via the traceable code.

(ii)This system achieves the dynamic interaction among client,server and browser,the server management and query of all information regarding the production process of Yinghong 9.By hierarchical authority and management,the authenticity and timeliness of the data can be realized.

(iii)It achieves the product identification and data security.The UHF RFID label having its own ID in conjunction with the traceable code is read,and they can be compared with the data in the database,to verify the authenticity of the product.It fully uses the feature of prohibiting covering the stored data to improve the storage security of the system,and ensure that the traceability system is not affected by the follow-up supply chain[16].

(iv)It effectively improves the standard management of enterprises.The running system involves all levels of the enterprise,and assigns business authorization.It can timely and quickly reflect the connection between the links,effectively save the business cost,and achieve corporate standard management.

In 2013,the brand value of Yingde black tea reached 1.088 billion yuan,ranking 30th in China[17].The intensification degree of production of Yingde black tea is increasingly high,and the black tea traceability system will be popularized and promoted.

However,the promotion and use of this system also need the joint participation of growers,processors,distributors,government regulators and consumers.The tracing data of black tea requires the managers to timely,accurately and truthfully upload the collected information to the server to complete the adding and checking of various data.It is necessary to strengthen the publicity and promotion of consumers'right to know,so as to supervise and perfect the traceable black tea products.

[1]YAN ZY,ZHONG JY.Design and implementation of green tea production information management system based on the critical stage of quality and safety[J].Agriculture Network Information,2011(10):33-35.(in Chinese).

[2]LUAN RP,ZHANG JF.Implementation of white tea quality and safety traceability system via Internet[J].Chinese Agricultural Science Bulletin,2011,27(20):137-140.(in Chinese).

[3]QIANH,NINGW.Research progress about tea traceability technology[J].Modern Agricultural Science and Technology,2009(14):23-25.(in Chinese).

[4]WANG FZ.Application of RFID technology in the tracking and tracing of tea quality safety[J].Newsletter of Seri culture and Tea,2008(1):34-35.(in Chinese).

[5]PENG GY.Isotopic element[M].Beijing:Beijing Agricultural University Press,1994.(in Chinese).

[6]KANGHN,YANG MF,CHEN B,et al.Trace element determination in teas and discrimination analysis for teas[J].Rock and Mineral Analysis,2006,25(1):22-26.(in Chinese).

[7]GUO BL,WEIYM,PAN JR.Progress in the application of isotopic fingerprint analysis to food origin traceability[J].Transactions of the Chinese Society of Agricultural Engineering,2007,23(3):284-289.(in Chinese).

[8]ZHAO JW,CHEN QS,ZHANG HD,et al.Study on the identification of tea using near infrared reflectance spectroscopy[J].Spectroscopy and Spectral Analysis,2006,26(9):1601-1604.(in Chinese).

[9]ZHAN ML,LIY,WEIYM,et al.Study on the tracking of tea producing areas using FI-IR spectral fingerprints analysis and pattern recognition analysis[J].Acta Agriculturae Nucleatae Sinica,2008,22(6):829-850.(in Chinese).

[10]RAOXQ,YINGYB,HUANGHB,et al.Identification of tea from different regions using X-ray fluorescence[J].Spectroscopy and Spectral Analysis,2009,29(3):837-839.(in Chinese).

[11]NIE GH.Distinction for different places of origin tea by thermo analysis[J].Hubei Agricultural Sciences,2004(5):77-78.(in Chinese).

[12]ZHAN Y,LU DB,SHANG JN.Study on traceability system of Longjing tea based on geographical indication[J].Computer Knowledge and Technology,2012(8):4415-4417.(in Chinese).

[13]Institute of Botany,Guangdong Academy of Agricultural Sciences.The certificate of Yinghong 9 tea variety accreditation,1988.(in Chinese).

[14]Nongbo Network.The geographical indication of black tea of England and Germany[EB].http://county.aweb.com.cn/2007/1/4/7363576.htm.(in Chinese).

[15]HU JT.The order by the Central People's Government of the People's Republic of China(No.49)—The law of the quality safety of agricultural products by the People's Republic of China[J].National People's Congress Executive Committee Bulletin of the People's Republic of China,2006,(5):337-342.(in Chinese).

[16]ZENG LC,SHEN Y,PENG JH,et al.Study on traceability system of farm products based on UHF RFID tags[J].Journal of Anhui Agricultural Sciences,2010,38(26):14734-14735 14740.(in Chinese).

[17]Brand Value Evaluation Research Group of Chinese Tea,Center for China Agriculture Brand of Zhejiang University.Assessment report on regional public brand value of Chinese tea(2009-2013)[J].China Tea,2013(5):4-12.(in Chinese).

杂志排行

Asian Agricultural Research的其它文章

- Quantile Regression Analysis on Convergence of China's Regional Econom ic Grow th

- A Study on Antibacterial Activity and Chem ical Com position of the Petroleum Ether Extract from Aspergillu sniger Mycelia

- Current Situation of Information Demand of Farmers in Taihang Mountain Area:A Case Study of Pingshan County in Hebei Province

- Analysis of the Influencing Factors and Key Driving Force concerning the Efficiency of Green Supply Chain of Fruits and Vegetables

- Study of the Option Ordering Policy concerning Perishable Farm Produce Based on Revenue Sharing Contract

- Study on Rural Poverty Reduction Effect of Traffic Infrastructure