3D Finite Element Model of Human Knee Injuries in the Traffic Accident

2014-04-08HUANGWeihuaHUANGPingLIZhengdongZOUDonghuaSHAOYuWANGHuijunCHENYijiu

HUANG Wei-hua,HUANG Ping,LI Zheng-dong,ZOU Dong-hua,SHAO Yu,WANG Huijun,CHEN Yi-jiu

(1.Department of Forensic Medicine,School of Basic Medical Sciences,SouthernMedicalUniversity,Guangzhou 510515,China;2.Shanghai Key Laboratory of Forensic Medicine,Institute of Forensic Science,Ministry of Justice,P.R.China,Shanghai 200063,China)

Introduction

Knee injuries are likely to occur in pedestrians during traffic accidents,and the knee injury mechanism is routinely required in forensic practice.With an aim to quantize the parameters of the injury mechanism of a healthy human knee[1],abundant materials properties of ligament elasticity and numerousreconstructionmethodsofknee models have been progressed to discover the role of ligaments and meniscus involvement in the sports[2-4]or knee injury[5-7].Additionally,the animal experiment on rabbits has been conducted to study the mechanical properties of ligaments[8].

Thephysicalandanimalmodelshavebeen widely used to promote the study on knee injury,but these models have failed to indicate the real impact.As previously reported,postmortem human knee was used as an experimental material;however,the in vitro experiments were performed without patella,patellar ligament,and surrounding soft tissues[9-10].The deficiency between the real knee and the model led to a great disparity in the analytic results;therefore,the mechanism could not be objectively verified.

Although the injury patterns can be displayed after post-processing[11],it can be hard to explain the injury process.Combinations of medical radiology and 3D modeling technology for knee injury can be likely to provide a relatively reliable approach to injury reconstruction.In the current study,finite element(FE)method was established to analyze knee injuries in the traffic accident and restore the injury process.

Material and methods

CT scanning

The tomography images of the human knee were derived from a male volunteer who had no history of skeletal disorders.In total,there were 262 slices of DICOM images from CT scans by 40-Slice MSCT(Siemens Ltd.,Germany),with a resolution of 512×512 volume pixels.

Mo del reconstruction

Mimics 15.0(Materialize lnc.,Belgium)was usedtoreconstructthehumankneemodelby sketching the different components such as femur,fibula,tibia,patella,meniscus,anterior cruciate ligament(ACL),posterior cruciate ligament(PCL),patellar ligament(PL),medial collateral ligament(MCL),lateral collateral ligament(LCL)and surrounding soft tissues[12-13].The manually,masks were built up as the stacking of sketched layers generated by defaultthreshold.The meniscus was reconstructed by filling intheinterspacebetweenfemurandtibiawith multiple-slice-edit function.Each part of the knee was created from the masks,and 3D model surfaces were smoothed to eliminate the insignificant details,and exported to Standard Triangulated Language(STL)format data,which were imported to 3-matic v6.1 software(Materialize lnc.,Belgium)for model refining and ligaments building.

The ligaments were manually created with the sketcher function of the 3-matic v6.1 software along the border of the bones and relocated to match up with the location in medical images.A flying impactor was constructed with a 142 mm×45 mm×10 mm rectangle of primitive object.All constructed parts of FE model were checked by fix-wizard function of the software to fix the errors derived from translation of the STL models.

Si mulation experiment

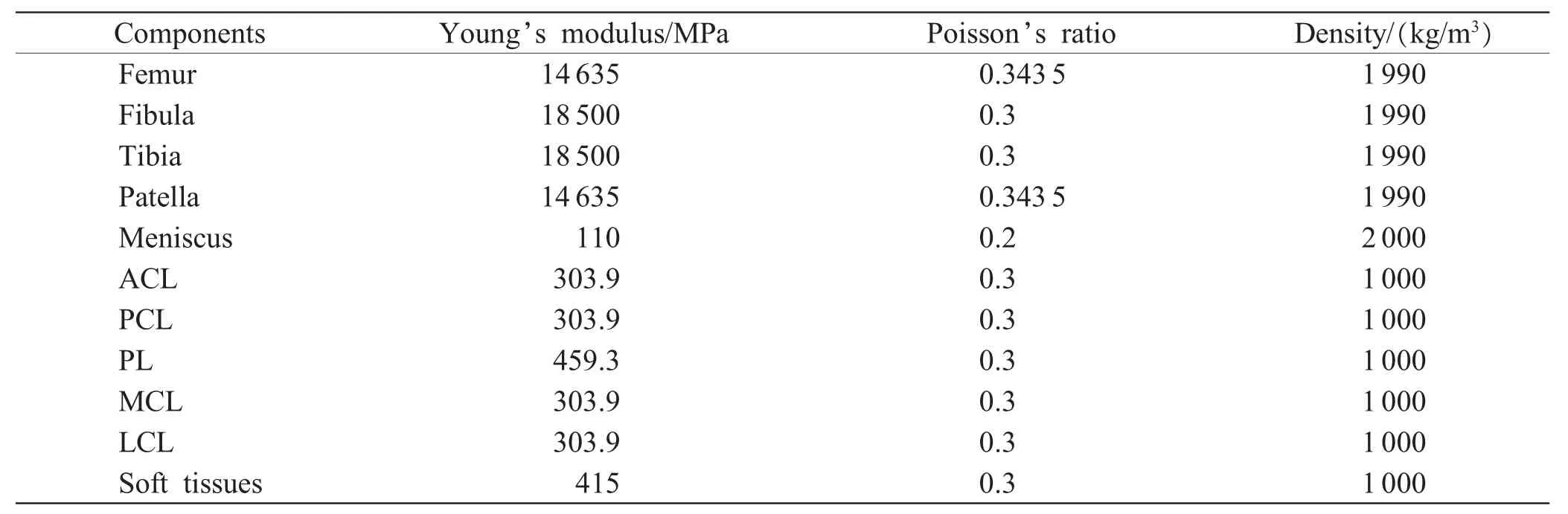

The meshed parts were assembled in ABAQUS software(SIMULIA,USA)to be an integral knee model,and the material properties of each part were defined by referring to the published literature[14](Table 1).

Table 1The material properties of FE knee model

The calculation formula of the step was selected as“Dynamic,Explicit”with an appropriated operation period[15],and the interactions among different parts included 18 contact pairs,accessible frictions and 13 attachment sites.Additionally,64 kg mass of body weight,2 kg mass of flying impactor,2 boundary conditions,gravity,and velocities were loaded,beforethemodelwaspre-calculatedfor checking and submitted to FE calculations.

The calculation were verified in different conditions,which included 10 m/s,20 m/s,and 40 m/s lateral impact[14].Further diagnostics were processed until the energy interrupt was eliminated.

Results

FE model

The sketched model of human knee was displayed in various colors(Fig.1A).Within Mimics 15.0 software,3D reconstructed model was generated with the sketched layers of slices from CT scanning(Fig.1B).

Fig.1The FE model of human knee

Me sh

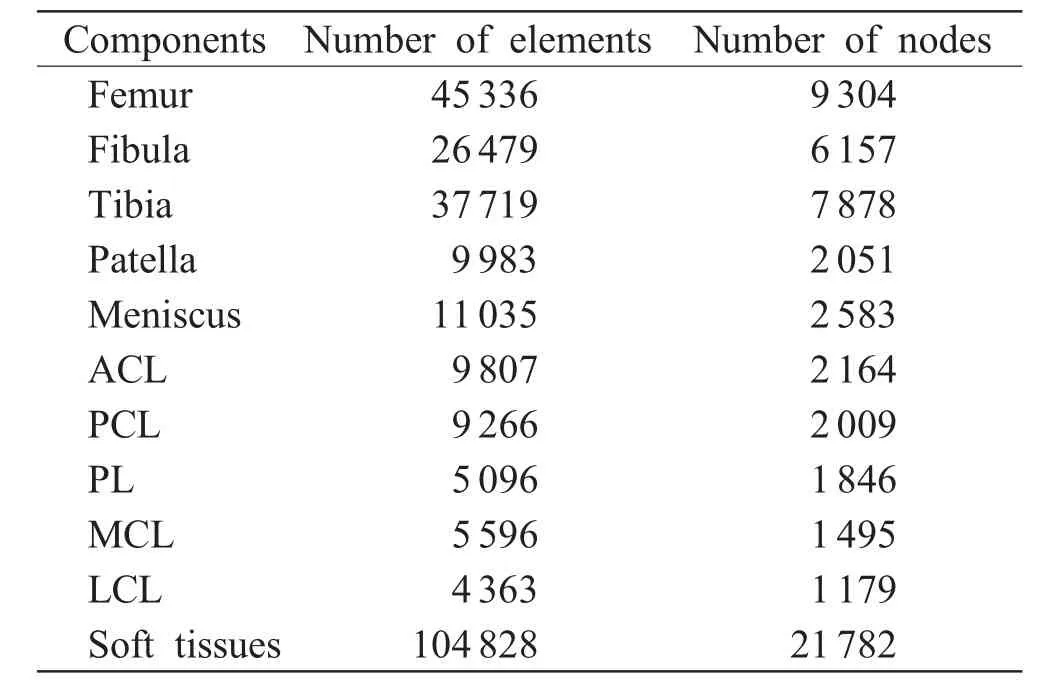

The entire model was defined as C3D4 tetrahedral solid elements in ABAQUS software.The impactor was defined as R3D4 quadrangular shell elements,because of the limited characteristic of discrete rigid body.The cultivated STL models were imported into ICEM CFD 13.0(ANSYS lnc.,USA).With the element quality of 0.45,each part of knee and the impactor were meshed with tetrahedral and quadrangle,respectively,after the topologic geometry were repaired for some petty anatomical structures withholding[16].The mesh results were checked and refined until they were stabilized(Table 2).To sum up,the human knee model consisted of 269508 tetrahedral solid elements,442 quadrangular shell elements,both translated into ABAQUS software as mesh parts.

Table 2 The mesh quality of human knee components

La teral impact of the knee

Thecommonimpactsweregeneratedunder various velocity conditions,which indicated that the ligaments of knee were tensed upon an impact,thus causing the slight deformation of PL,serious injuries of LCL and meniscus.During the simulated injury process,the LCL and the lateral meniscus were largely deformed in the collision zone(Fig.2).As indicated by the color of red in the region,furthermore,the stress was generated more than 40 MPa(Fig.2).

At the speed of 10 m/s,slight stress concentrations were discovered at both ends of ACL and PCL.At the speed of 20m/s,serious stress concentrations were distributed in the intermediate and at both ends of ACL,PCL,MCL,and LCL,while the meniscus stress was mainly distributed in the impact region.The whole knee model was seriously injured across the impact direction at 40 m/s(Fig.2).The maximum stress of inner soft tissues during collisions showed almost the same distribution trend as the maximum strain(Table 3-4).

Ti me of collision

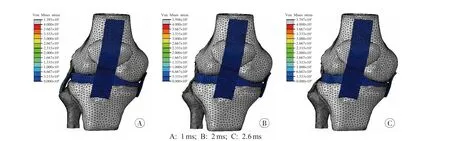

During the period of impact,the stress distribution of ligaments and meniscus showed that LCL and cruciate ligament were stretched at 1 ms.LCL was seriously deformed,and other ligaments and meniscus started deforming and displacing at 2 ms.All ligaments andmeniscus wereseriously deformed,the suffering stress reaching the highest value during the impaction at 2.6ms(Fig.3-4).

Fig.2The simulated impact result at 40m/s

Table 3The maximum stress of inner soft tissues during collisions(MPa)

Table 4The maximum strain of inner soft tissues during collisions

Fig.3The stress distribution of outer ligaments and meniscus after impact contacted at 40m/s

Fig.4The stress distribution of inner ligaments after impact contacted at 40m/s

Se lection of analytical source

With the different impact loading conditions of the knee model performed,the mostly affected area of the soft tissues across the collision zone were marked,such as the middle region of the LCL and cruciate ligaments,the lateral region of the meniscus,and the femur end of MCL,with 14 367 elements selected as the basic source for an analysis of the soft tissues injury mechanism.

Mo del validation

The purpose of model validation was to ensure its rationality and reliability,and to produce biophysical performances of biological material tissues[17].In the current study,nevertheless,the validation of ligaments was difficult to achieve in the situation of compressive force 1150N and anterior force 134N[18],for there were still few related experiments in the published literature.

In jury prediction

As a procedure to determine the injury mechanism,both stress and strain were compared between the current collision simulations and those previously reported.As the impact is most likely to be imposed on a walking pedestrian as a victim,the biological features of the soft tissues were required for the construction of the current model.Therefore,the generated stress and strain were used as reliable criteria for predicting the injury risk of soft tissues[19],as indicated by the stress more than 36.4 MPa and strain more than 0.15[20].

By comparison,the results showed the stress at 40m/s impact was much higher than that previously reported[20];the stress of LCL was 4.6 times higher under the impact condition,followed by the meniscus 1.7 times,ACL 1.6 times and PCL 0.03 times;at 20 m/s,the stress of LCL was 1.1 times higher under the impact condition.

Additionally,the results showed the strain at 40 m/s impact was much higher;the strain of LCL and meniscus were 3.4 times higher under the impact condition than that previously reported[20],followed by MCL 2.2 times;at 20 m/s,the strain of meniscus was 0.14 times higher than that previously reported[20];and at 10m/s,there was no distribution of stress or strain recorded.

Discussion

During the past decade,Wang et al.[1]shifted the injury research of the FE method from quality description to quantity analysis.This was because of the value of prediction was too wide in range,which led to a vague explanation for the injury process.Therefore,the research on different parts of body injury was performed in order to obtain a better result from injury explanation,such as the injury of head[21],torso[22],limb[15]and joint[23].In case of knee injury,different main components of a knee model has been established for further investigations,such as the injury of ACL[24],PCL[25],MCL[26]and menisci[27].

Model construction

As previously reported,the ligaments and soft tissues were presented as some exhibited straight lines or pieces of shell elements by inducing aproper thickness[16,28-29],which obviously cannot satisfy the structural appearance of a real human prototype.In the current study,the FE model was modifiedassimilarastherealanatomicalstructure,which aimed to obtain a more accurate result for injury mechanism.It consisted of the improved appearance of ligaments,the outbound soft tissues,the higher quality of mesh and element.The bigger volume of mesh could satisfy the response of energy or impact force,but not be sensitive enough to the small changes of stress or strain[30].

Since then,there has been much literature on the injury model of knee with the FE method[16,20,31-33].In the investigation on traffic injuries of the lower limbs,a flying impactor was used to simulate the knee injury under 10 m/s,20 m/s and 40 m/s speed of velocity.In reality,the current model improved both the construction and element number.

El ement type usage

For the complexity of STL format 3D model,errors could be produced during the transformation between different forms of software.Therefore,the accumulation of flaws could affect the element mesh quality and the result accuracy.Consequently,the preprocessing of the human knee model required the criteria of higher quality so as to avoid error termination during the calculation.Given the complex knee geometry,meshing efficiency and computational stability,the tetrahedron element was chosen as the main composition for the FE knee model.

In fluence of stress and strain

The surrounding soft tissues played an important role in the ligaments movement limitation and the bones protection,especially at a collision of lower speed.The reason was that the flexible soft tissues absorbed most of the kinetic energy in the impact process.

LCL could be hurt at 40 m/s.The possible mechanism was the compression between the outer soft tissues and the inner bones caused ligament sensitivities to the stretching and deforming.The lateral meniscus was wounded at the speed higher than 20 m/s,mostly caused by the direct force effect and the crushing between femur condyle and tibia plateau,with obvious stretching and deforming.It also might be caused by the weakness of flexible biological material,thereby performed poorly when compression occurred.

MCL was injured at 40m/s as a reason for the position of these ligaments paralleled to the pathway of collision,and the fixations of both ends of the bone were displaced during the process.

ACL presented with a higher risk of being injured over 20 m/s than PCL,with an probable reason that the ligament lay deep within the knee joint,which was not only protected by the meniscus,but also limited the movement from femur and tibia.As such,the ligament mainly bore the pressure from body weight,and little elongation could be observed.

PL was not injured under all impacts as there werenodirectimpactsandligamentsstretching during the process.

Di fference of collision sites

Thestressdistributionof theligamentsand meniscus were not totally coincided,for the structureoftheligamentswerenotrectangularbut cuboidshell.Duringthecollision,theligaments were irregularly deformed,thus causing the tension transmission to become unevenly distributed.In addition,the internal pressure of the knee joint led to a difference of stress distribution between core and peripheral part of the solid ligament.The combined effect could cause different maximum stress areas of ligaments.

Li mitations and suggestion

Due to the complexity of the current knee model,the elements were distorted under higher flexion degree and longer impaction period.Therefore,further investigations are needed on more injury loading conditions in order to obtain more information about the human knee flexion processes,ligament tensions,and impacts with different velocities.

The ligaments were manually sketched because of the limited distinguishing capacity of CT scanning images.Therefore,a better FE model reconstruction and fixation method was required.Moreover,both the initial stress and the nature muscles pre-tension were absent in this simulation because it was difficult to conduct tension simulation during the movement phases.

Conclusion

Apparently,the current knee FE model showed that most of the ligaments were wounded at 40 m/s of lateral impact;and that no injury occurred at 10 m/s as the protection from the surrounding soft tissues.Therefore,the model was verified to be effective in investigating the injury mechanism during lateral impaction.

Thecurrentstudywasfundedbythe12th Five-year National Plan for Science and Technology(No.2012BAK16B02),the Council of National Science Foundation of China(No.81102300,81273338),the Science and Technology Commission of Shanghai Municipality(No.13DZ2271500)and the Science Foundation of IFS(No.GY2013Z-3).

[1]Wang Q,Gabler HC.Review of correlation methods for evaluating finite element simulations of impactinjury risk[J].Biomed Sci Instrum,2008,44:268-273.

[2]Nechita F.Biomechanics in sport[J].Bulletin of the Transilvania University of Bras¸ov,2009,51(2):135-138.

[3]Valkeapää A,Kłodowski A,Rantalainen T,et al.Knee cartilage surface loading during stationary bicycling[C]//The 19th International Conference on Computer Methods in Mechanics,Poland:Warsaw,2011.

[4]Sigward S,Powers CM.The influence of experience on knee mechanics during side-step cutting in females[J].Clin Biomech(Bristol,Avon),2006,21(7):740-747.

[5]Limtrakarn W,Phakdeepinit W.Biomechanics study of knee ligament[C]//The First TSME International Conference on Mechanical Engineering,Ubon Ratchathani,2010.

[6]Lawrence RK 3rd,Kernozek TW,Miller EJ,et al.Influences of hip external rotation strength on knee mechanics during single-leg drop landings in females[J].Clin Biomech(Bristol,Avon),2008,23(6):806-813.

[7]Ramaniraka NA,Saunier P,Siegrist O,et al.Biomechanical evaluation of intra-articular and extra-articular procedures in anterior cruciate ligament reconstruction:a finite element analysis[J].Clin Biomech(Bristol,Avon),2007,22(3):336-343.

[8]Yamamoto S,Saito A,Nagasaka K,et al.The strainrate dependence of mechanical properties of rabbit knee ligaments[C]//The 18th International Technical ConferenceontheEnhancedSafetyofVehicles,Japan:Nagoya,2003.

[9]Mallesh G,Sanjay SJ.Finite element modeling and analysis of prosthetic knee joint[J].International Journal of Emerging Technology and Advanced Engineering,2012,2(8):264-269.

[10]Hao ZX,Leng HJ,Qu CY,et al.Biomechanics of the bone and the knee joint[J].Chinese Journal of Solid Mechanics,2010,31(6):603-612.

[11]Belvedere C,Ensini A,Feliciangeli A,et al.Geometrical changes of knee ligaments and patellar tendon during passive flexion[J].J Biomech,2012,45(11):1886-1892.

[12]Dong YF,Dong YH,Hu GH,et al.A method for accurate reconstruction of subject-specific anatomical finite element model of knee joint[J].Journal of Clinical Orthopaedics,2011,14(2):198-203.

[13]Kamal R,Kumar DA.Three-dimensional(3D)modeling of the knee and designing of custom made knee implant using mimics software[J].International Journal of Current Engineering and Technology,2013,3(2):327-330.

[14]Li Z,Zou D,Liu N,et al.Finite element analysis of pedestrian lower limb fractures by direct force:the result of being run over or impact?[J].Forensic Sci Int,2013,229(1-3):43-51.

[15]Homyk A,Orsi A,Wibby S,et al.Finite element analysis of the knee:development of a failure locus for the anterior cruciate ligament[C]//ASME 2010 Summer Bioengineering Conference,2010:16-19.

[16]Junior MT,Fancello EA,de Mello Roesler CR,et al.Three-dimensionalnumericalsimulationofhuman knee joint mechanics[J].Acta Ortop Bras,2009,17(2):18-23.

[17]Song Y,Debski RE,Musahl V,et al.A three-dimensional finite element model of the human anterior cruciate ligament:a computational analysis with experimental validation[J].J Biomech,2004,37(3):383-390.

[18]Kazemi M,Dabiri Y,Li LP.Recent advances in computational mechanics of the human knee joint[J].Comput Math Methods Med,2013,2013:718423.

[19]Butler DL,Goldstein SA,Guilak F.Functional tissue engineering:the role of biomechanics[J].J Biomech Eng,2000,122(6):570-575.

[20]Soni A,Chawla A,Mukherjee S.Effect of muscle contraction on knee loading for a standing pedestrian in lateral impacts[C]//Proceedings of the 20th International Technical Conference on the Enhanced Safety of Vehicles(ESV),2007.

[21]Takhounts EG,Ridella SA,Hasija V,et al.Investigation of traumatic brain injuries using the next generation of simulated injury monitor(SIMon)finite element head model[J].Stapp Car Crash J,2008,52:1-31.

[22]Shao Y,Zou D,Li Z,et al.Blunt liver injury with intact ribs under impacts on the abdomen:a biomechanical investigation[J].PLoS One,2013,8(1):52366.

[23]Tarnit¸ǎ D,Boborelu C,Popa D,et al.The three-dimensional modeling of the complex virtual human elbow joint[J].Rom J Morphol Embryol,2010,51(3):489-495.

[24]Ali N,Rouhi G,Robertson G.Approaches to non-contact anterior cruciate ligament injury studies:utility of operations research and artificial intelligence[J].Transactions of the Canadian Society for Mechanical Engineering,2011,35(2):145-159.

[25]Bowman KF Jr,Sekiya JK.Anatomy and biomechanics of the posterior cruciate ligament,medial and lateral sides of the knee[J].Sports Med Arthrosc,2010,18(4):222-229.

[26]Peck L,Billiar K,Ray M.Dynamic failure properties of the porcine medial collateral ligament-bone complex for predicting injury in automotive collisions[J].Open Biomed Eng J,2010,4:77-84.

[27]Li LP,Kazemi M.Fluid pressurization in cartilages andmenisciinthenormalandrepairedhuman knees[M]//Alexandru C.Modeling and Simulation in Engineering.InTech,2012.

[28]Beillas P,Papaioannou G,Tashman S,et al.A new method to investigate in vivo knee behavior using a finite element model of the lower limb[J].J Biomech,2004,37(7):1019-1030.

[29]Plochocki JH,Ward CV,Smith DE.Evaluation of the chondral modeling theory using fe-simulation and numeric shape optimization[J].J Anat,2009,214(5):768-777.

[30]Franz U,Gromer A,Walz M,et al.Ideas on applying very fine models in dummy model development[C]//10th International LS-DYNA®Users Conference,2008.

[31]Peña E,Calvo B,Martínez MA,et al.A three-dimensional finite element analysis of the combined behavior of ligaments and menisci in the healthy human knee joint[J].J Biomech,2006,39(9):1686-1701.

[32]Untaroiu C,Darvish K,Crandall J,et al.Characterization of the lower limb soft tissues in pedestrian finite element models[C]//The 19th International Technical Conference on the Enhanced Safety of Vehicles.USA:Washington DC,2005.

[33]Takahashi Y,Kikuchi Y.Biofidelity of test devices and validity of injury criteria for evaluating knee injuries to pedestrians[C]//The 17th International Technical Conference on the Enhanced Safety of Vehicles,Netherlands:Amsterdam,2001.