Experimental study on capacity of bubble to carry water

2013-09-21WANGYongJINLianganCHIWeiQUYi

WANG Yong,JIN Liang-an,2,CHI Wei,QU Yi,2

(1.Dept.of Navigation,Dalian Naval Academy,Dalian Liaoning 116018,China;2.Dalian Institute of Chemical Physics,Chinese Academy of Sciences,Dalian Liaoning 116023,China)

0 Introduction

Movement of rising bubble exists in the nature,such as rivers,lakes or sea.And it has been widely applied in chemical,environmental and maritime engineering or shipping fields etc[1-3].There are numerous experimental and theoretical studies focused on hydrodynamic characteristic of rising bubble in liquid,the influence of liquid characteristics on bubble behaviors,and the interaction between bubbles[4-11].But the interaction of bubble and surrounding liquid has not been studied.However,the interaction effect,especially the carrying effect of rising bubble,can directly influence on the fluid behavior and the transmittal efficiency of gas-liquid two-phase flow.So far it is a key point in design of engineering.In recent years,velocity field around rising bubble has been extensively studied by numerical simulation[12-15].However, lacking measurement method makes it hard to find experimentally measured results to validate these numerical simulations[16-17].Therefore,it is a realistic need to find an appropriate method to measure it accurately.

Rising bubble's effect of carrying surrounding water is so complicated.It will not only induce an up-flow phenomenon in vicinity,but also a down-flow in outer region.However,its capacity to induce up-flow is more considerable in most industrial applications,such as bubble floatation and ship bubble wake removing[18].In order to provide more scientific basis for engineering application,this paper took bubble in water as an example,introduced a new concept,volume of up-flow water carried by bubble,to describe bubble capacity to carry water,and tried to find a feasible technology to measure it accurately.

1 Material and method

1.1 Design of method

In bubble rising process,a range of vicinity water will move upward because of the interaction between two phases of gas and liquid,while the boundaries range is obviously difficult to determine.And the volume of upflow water carried by bubbles rising in water to a certain depth can be used to describe bubble's capacity to carry water.But this part of up-flow water was mixed with the still or down-flow water in outer region,so it is not easy to separate bubble carrying up-flow water effectively,even is difficult to measure it accurately for its small volume.In view of this,a novel method,dual-liquid separation and phase-change measurement,was put forward,its basic idea was introduced as follows.

Dual-liquid system is composed of two immiscible liquid with different densities.In the experiment,diesel fuel and water were chosen.When they were mixed,an interface would naturally appear with their density difference,the up-liquid layer was diesel fuel,and down-liquid layer was water.When bubble rising in down-liquid(water)went beyond the interface,up-flow water surrounding bubbles would be carried to the up-liquid layer(diesel fuel).Simultaneously,under the carrying effect of diesel fuel's stable revolving,up-flow water just car-ried into up-liquid layer would be taken away from the upper region of down-liquid pool,and subside to the bottom of up-liquid pool for their density difference.So bubble carrying up-flow water would be successfully separated from the other water in the vicinity of bubble.

As the volume of up-flow water is generally small,it is difficult to measure it accurately.So phase-change measurement was put forward,its basic idea was making separated up-flow water react rapidly and completely with sufficient special chemical to change the carried water from liquid-phase into gas-phase.For the volume of gas is about thousand times larger than that of water,it could be measured much more easily and precisely.And then,the volume of up-flow water carried by bubbles could be calculated accurately with measured gas volume by the ratio of gas-liquid volume in phasechange reaction.

1.2 Design of experimental apparatus

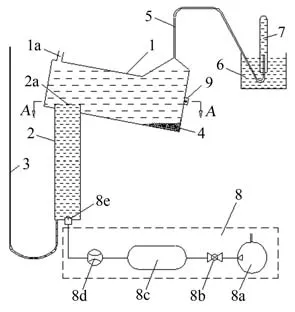

Based on the thought of dual-liquid separation and phase-change measurement,the experimental apparatus was specially designed,which includes separation device,phase-change device and basic device.

1.2.1 Separation device

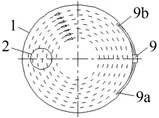

Separation device was used to separate up-flow water carried by bubble.It was composed of two joined columniform container with different radius,named upperpool(1)and down-pool(2)respectively according to relative position(Fig.1).The diameter of the down-pool was smaller than the radius of upper-pool.The upperpool was inclined at a certain angle with its bottom lower than the topmost surface of the down-pool.In order to form a perfect up-liquid flow field,the down-pool should be located in the higher part of upper-pool.Fig.2 is the section sketch of A-A line of up-pool,which illustrates the device to form up-liquid flow field.In Fig.2,special oil pump is fixed outside of the upper-pool,its inlet and outlet are located on the inner wall of an upperpool,above the topmost surface of the down-pool.

Fig.1 Experimental apparatus图1 双液分离转相精测装置

Fig.2 Device to form up-liquid flow field图2 上液流场形成装置

1.2.2 Phase-change device

Phase-change device(Fig.1)was used to make specific chemical reactions,transform seperated up-flow water from liquid-phase to gas-phase,collect the gas and measure its volume.It was composed of two parts:one was phase-change reaction zone(4),the other was produced gas collection zone(5,6,7).Phase-change reaction zone was the lowest part of the upper-pool.Specific phase-change chemical set in advance would react with the seperated water rapidly and completely.Produced gas collection zone was used to collect gas produced in phase-change reaction.This part of the apparatus consist of gas collection tube(5),liquid container(6)and gas collector(7).

1.2.3 Basic device

Basic device was composed of bubble generator and interface controller.

Bubble generator included compressed air source device(8a),check valve(8b),gas container(8c),gas flowmeter(8d)and nozzle(8e).The nozzle's diameter,shape,vertical depth and horizontal position were designed to be adjusted purposefully.

Interface controller was connected with down-pool,and used to keep the dual-liquid interface(2a)locating at the topmost surface of down-pool.

1.2.4 Device parameters

As the design showed in 1.2.1 to 1.2.3,the parameters of the device were set up as follow:the upperpool was50cm diameter and 24cm height,its inclination was 3°;down-pool was 21cm diameter and 55cm height,it was located in the highest position of the upperpool.In experiments,0.5ml air was injected to form bubbles.To control small volume process conveniently,bubble generator was simplified,it was composed of 2ml syringe,infusion tube,and 2.5mm diameter nozzle.The nozzle was located in the center of down-pool,52cm away from the dual-liquid interface.

1.3 Method

In experiments,dual-liquid was water and diesel oil.0.5ml air was injected into water to form bubbles at normal temperature(20℃)and air pressure.When the up-flow water carried by bubble went beyond the interface and into the diesel oil,it would be effectively separated to the lowest part of upper-pool with the effect of stable revolving up-liquid flow and density difference.In this condition,volume of separated water was measured respectively by two methods,phase-change measurement and direct measurement,to compare their precision.

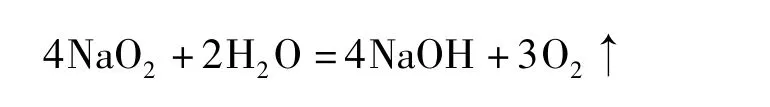

In method of phase-change measurement,adequate phase-change chemical(NaO2)was put in phase-change reaction zone in advance to react with separated up-flow water rapidly and completely.Moreover,produced gas(O2)was gathered to measure its volume(Vg)by 1000ml cylinder(Minimum scale 10ml),and the phasechange measuring volume of up-flow water(Vw1)could be calculated with gas-liquid volume ratio in phasechange chemical reaction.

In method of direct measuring,separated up-flow water was managed to move away from the up-pool,and the volume would be measured by 20ml pipette or 10ml measuring cylinder(Minimum scale 0.1ml).So the direct measuring volume of up-flow water(Vw2)was got.

In order to avoid the influence of measuring error,all of the experiments were repeated 10 times,and every repeat had 10 samples.

2 Results and discussion

2.1 Experimental results

The data were showed in Tab.1,including the volume of gas produced in phase-change reaction(Vg),phase-change measuring volume of up-flow water(Vw1)deduced by Vg,direct measuring volume of up-flow water(Vw2),and relative error((Vw2-Vw1)/Vw1).

Table 1 Volume of up-flow water carried by bubbles with different measurements(Average±Standard error)表1 气泡上升携带水量的比对测量实验结果

In Table 1,the average of phase-change measuring water volume is about 1.76311ml,its standard error is±0.0026~0.0040.While the average of direct measuring water volume is 1.743ml,its standard error is±0.043~0.130.Furthermore,the maximum relative error of each pair data is about 13.47%,the minimum is only 0.51%,and the average relative error is about 5.798%.

2.2 Analysis and discussion

Result shows that up-flow water volume carried by bubbles could be measured more accurately by dual-liquid separation and phase-change measurement.It is mainly due to enlargement measuring with phase-change by special chemical reaction,which reduces the influence of estimation error obviously.

Supposed that up-flow water volume was measured directly with 20ml pipette or 10ml graduated flask(minscale 0.1ml),the estimate error was about 0.01ml,occupying 0.57%of the average value(1.743ml).While in dual-liquid separation and phase-change measurement,water has been changed into gas,and its volume has been enlarged about 2000 times.Although the estimate error of produced gas volume was 1ml,occupying only 0.03%of the average volume(3290.9ml),it didn't have obvious effect on measuring accuracy.That is to say,the larger produced gas volume could be measured more accurately than smaller up-flow water volume.

In addition,the up-flow water volume measured by phase-change measurement would be calculated with produced gas volume.In experiments,NaO2was chosen as phase-change chemical,and the reaction equation was:

According to this equation,the molar ratio of produced gas(O2)and liquid(H2O)is 3∶2,so the gasliquid volume ratio is 1866.6∶1.That is to say,to get the up-flow water volume,produced gas volume would be reduced nearly 2000 times,so the impact of estimate error on the measuring result would be furthermore reduced,even could be negligible,and the up-flow water volume could be measured more accurately.So the feasibility of dual-liquid separation and phase-change measurement was validated.

Moreover,the choice of phase-change material would influence the gas-liquid volume ratio of phasechange chemical reaction,and directly affected the accuracy of dual-liquid separation and phase-change measurement.

In experiments,the chosen phase-change material should be stable in diesel fuel,and react with water quickly.The produced gas should be insoluble in water,and the resultant of reaction should be non-corrosive or low-corrosive.The phase-change material we can choose usually includes:active alkali metal or alkaline-earth metals,Li,Na,K,etc;alkali metals and alkalineearth metal hydride,NaH,CaH2,KH,etc;peroxide and superoxide,CaO2,CaO4,etc;metal carbides,Al4C3and so on.When different phase-change material was chosen,the volume of produced gas is about 300 to 2000 times than that of water.With the larger volume ratio of gas and liquid,the measuring error of dual-liquid separation and phase-change measurement is smaller,so its accuracy is relatively higher.

Result also shows that the superiority of dual-liquid separation and phase-change measurement is more obvious in smaller volume system.

With ascending sort the phase-change measuring volume of up-flow water carried by bubble,we can get Fig.3.

Fig.3 Compare of up-flow water volume by different measurements图3 气泡上升携带水量测量结果的比较

As Fig.3 shows,data in these two methods,direct measurement and phase-change measurement,are all in the range of 1 ~2.5ml,and the direct measuring group is generally smaller.When the volume of bubble carrying up-flow water is relatively larger,two measuring data are nearly equal,such as the sixth,seventh,eighth and tenth groups in Fig.3.However,while up-flow water volume is small,the relative error of these two measuring data will become obvious,such as the first,second,forth and fifth groups.So the feasibility of dual-liquid separation and phase-change measurement was validated.Especially when the water volume is smaller,phase-change method can accurately offer the volume of up-flow water carried by bubbles,but direct method can not for its too big inherent error.

3 Conclusions

In order to solve the problem of lacking method to separate and measure up-flow water carried by bubble,experimental apparatus was specially designed.With water and diesel oil as dual-liquid system,the volume of up-flow water carried by bubble was measured by two different methods:direct measurement and phasechange measurement.Results show that up-flow water carried by bubble can be effectively separated,and that the phase-change method of measuring dual-liquid separation is precisely higher than that of direct measurement.Phase-change method can accurately offer the volume of up-flow water carried by bubbles especially in small volume system than direct measurement method which has a big inherent error.So it was validated that dual-liquid separation and phase-change measurement is valuable to deeply experimental study of bubble's capac-ity to carry surrounding water.

Moreover,it was also observed that measuring precision of this new technology might be influenced by many factors,such as dynamic viscosity of up-liquid,environmental temperature and air pressure,bubble size and distribution,and entireness of phase-change reaction et al.These influence rules will be deeply investigated in the future.

:

[1] CHE De-fu,LI Hui-xiong.Multiphase fluid and its application[M].Xi'an:Xi'an Jiaotong University Press.2007.

[2] DENG Sheng,LI Hui-xiong,ZHAO Jian-fu,et al.Numerical simulation of the interface movement in gas-liquid two-phase flows[J].Journal of Xi'an Jiaotong University.,2004,38(11):1123-1127.

[3] ZHANG Lei,LIU Ping,LIU Chun,et al.Micro-bubbles and its application in control of environmental pollution[J].Hebei Journal of Industrial Science and Technology,2011,28(1):59-63.

[4] CLIFT R,GRACE J R,WEBER M E.Bubbles,drops,and particles[M].New York:Academic Press,1978.

[5] JIA Fu,LIU Yi-nian,CHEN Xue-wu.Turbulence characteristics of rising bubble cluster[J].Science in China,Ser.A,1991,34(5):486-493.

[6] CHEN N C,CHOU I S.Wake structure of a single bubble rising in a two dimensional column[J].Experimental Thermal and Fluid Science,1998,17(3):165-178.

[7] SMOLIANSKI A,HAARIO H,LUUKKA P.Numerical study of dynamics of single bubbles and bubble swarms[J].Applied Mathematical Modelling,2008,32(1):641-659.

[8] AMAYA-BOWER L,LEE T.Single bubble rising dynamics for moderate Reynolds number using lattice Boltzmann method[J].Computers & Fluids,2010,39(7):1191-1207.

[9] JIANG Shao-kun.Bubble behavior in non-Newtonian fluids[D].Tianjin:Tianjin University,2007.

[10] WANG Han,ZHANG Zhen-yu,YANG Yong-ming,et al.Surface tension effects on the behavior of two rising bubbles[J].Journal of Hydrodynamics,Ser.B,2011,23(2):135-144.

[11] YU Zhao,YANG Hui,FAN Liang-shi.Numerical simulation of bubble interactions using an adaptive lattice Boltzmann method[J].Chemical Engineering Science,2011,66(14):3441-3451.

[12] ELLINGSEN K,RISSO F.On the rise of an ellipsoidal bubble in water oscillatory paths and liquid-induced velocity[J].Journal of Fluid Mechanics,2001,440(1):235-268.

[13]SANADA T,WATANABE M,FUKANO T,et al.Behavior of a single coherent gas bubble chain and surrounding liquid jet flow structure[J].Chemical Engineering Science,2005,60(1):4886-4900.

[14] FAN Wen-yuan,MA You-guang,LI Xiao-lei,et al.Study on the flow field around two parallel moving bubbles and interaction between bubbles rising in CMC solutions by PIV[J].Chinese Journal of Chemical Engineering,2009,17(6):904-913.

[15]AMAYA-BOWER L,LEE T.Numerical simulation of single bubble rising in vertical and inclined square channel using lattice Boltzmann[J].Chemical Engineering Science,2011,66(5):935-952.

[16] XU Shang,WANG Yong,HAN Yun-dong,et al.Influence of air injecting rates on bubble's capacity to carry water[J].Chemical Engineering(China),2011,39(6):76-78.

[17] WANG Yong,JIN Liang-an,XU Shang,et al.Experimental research for influence of injecting depth on water volume carried by bubbles[J].Journal of Experiments in Fluid Mechanics,2011,25(6):49-53.

[18] TIAN Heng-dou.Study on control technology of ship bubble wake[D].Dalian:Dalian Naval Academy,2011.