洛神花纤维增强通用树脂复合物的力学性能及其化学镀镍金属化

2011-11-16KOTAVENKATACHALAMKARTHIKEYANNARAYANANPANDIVELAN

KOTA B, VENKATACHALAM G, KARTHIKEYAN S*, NARAYANAN S, PANDIVELAN C

洛神花纤维增强通用树脂复合物的力学性能及其化学镀镍金属化

KOTA B, VENKATACHALAM G, KARTHIKEYAN S*, NARAYANAN S, PANDIVELAN C

洛神花纤维采用5%的氢氧化钠溶液处理后用于制备纤维增强型通用树脂复合物。对含不同纤维体积分数的复合物的拉伸行为进行研究后发现,其力学性能与传统复合物类似。复合物的抗拉强度随着纤维含量的增大而提高。采用化学镀镍工艺对复合物进行金属化后,其显微硬度是原来的7倍。

洛神花;通用树脂;复合物;化学镀镍;金属化;力学

2 Experimental

2. 1 Preparation

The gongura fiber was obtained from the stem of gongura plants. In order to reduce its moisture absorption and to improve its adhesive property, the fiber was treated chemically. The fiber was dipped in the solution of 5% NaOH for 24 h and 48 h. After that it was dried to remove the presence of moisture. This chemical treatment helps to increase the surface roughness for better mechanical interlocking. Then the fiber is ready for composite making. The matrix was prepared with general purpose (GP) resin. Catalyst and accelerator were added to GP resin for improving its curing and adhesiveness with fiber. Composites with different volume contents of fiber were prepared.

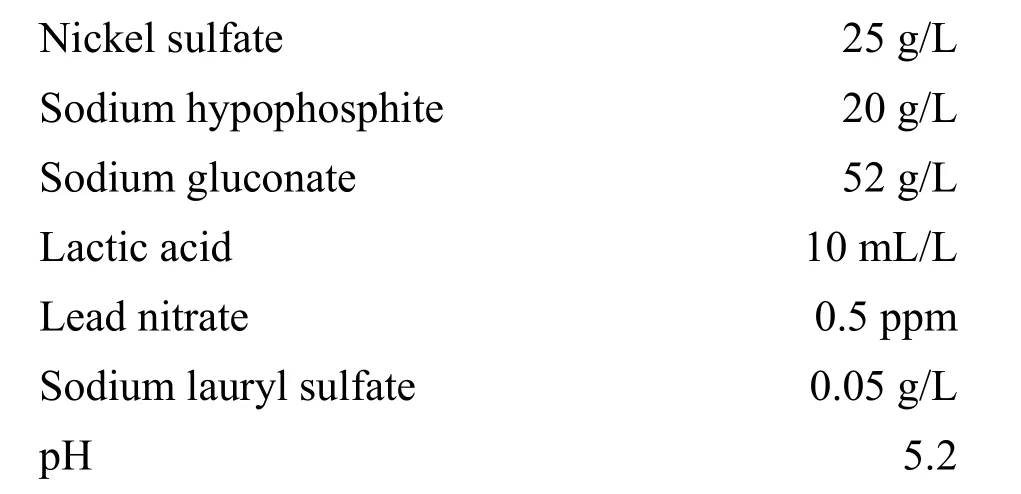

The bath used for metallization of composite had the following composition of A.R. grade chemicals:

2. 2 Testing and evaluation

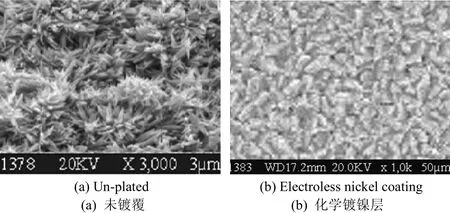

The tensile behaviors of fiber and composite were studied using an electronic tensiometer (shown in Figure 1). The specimen (shown in Figure 2) was cut and the tensile test was carried out for the fibers treated for 24 and 48 hours respectively and four composites made from these fibers with 20% and 40% volume fractions respectively. The microhardness of the as-prepared and metalized composites were measured by a Vickers hardness tester at a load of 100 g. SEM photographs were portrayed for the composite before and after metallization at a magnification of ×1 000 to ascertain the surface morphology. Analysis of Ni and P was made by X-ray analytical microscope (XGT-5000 series). The thickness of Ni–P deposit was 38 µm.

Figure 1 Tensiometer图1 拉伸测试仪

Figure 2 Gongura fiber-reinforced composite图2 洛神花纤维增强复合物

3 Results and discussion

3. 1 Stress-strain behavior studies

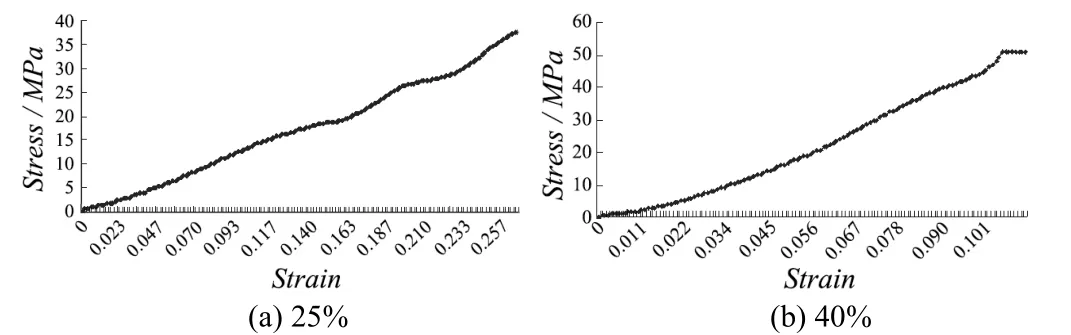

The stress-strain behaviors of the fibers treated for 24 hours and 48 hours respectively are shown in Figure 3a and 3b. The maximum stress developed is 78 MPa for the first 24 hours-treated fiber and 52 MPa for the 48 hourstreated one. The reason for this is because at longer duration of treatment, excess delignification of natural fiber occurs resulting in a weaker or damaged fiber. The stress-strain behaviors of the polymer matrix composites with 25% and 40% gongura fiber treated for 24 hours are given in Figure 4a and 4b, respectively. The maximum stresses developed in both types are 38 MPa and 51 MPa. It is evident that the increase in the volume of fibers in composite increases its strength. The Figure 5a and 5b show the stress-strain behavior of the composites obtained with 25% and 40% fibers treated for 48 hours. The maximum stresses developed in both types are 37 MPa and 49 MPa, respectively.

3. 2 Microhardness measurements

The Vickers hardness measurements showed that the metalized composite has an enhanced microhardness value of 550 VHN which is 7 times greater than that of pure composite (77 VHN). These results are in good agreement with those reported earlier for electroless nickel coatings[6-11].

Figure 3 Stress-strain curves for the fibers treated for different time图3 处理不同时间的纤维的应力–应变曲线

Figure 4 Stress-strain curves of the composite with different volume fractions of 24 h-treated fibers图4 由不同体积分数的纤维(经24 h处理)制备的复合物的应力–应变曲线

Figure 5 Stress-strain curves of the composite with different volume fractions of 48 h-treated fibers图5 由不同体积分数的纤维(经48 h处理)制备的复合物的应力–应变曲线

3. 3 Surface morphology and elemental composition The Figure 6a gives a SEM photograph indicating the apperance of needle-like structure due to the formation of crystaline composite. For the metalized composite (Figure 6b), it is seen that the structure is amorphous due to incorporation of Ni–P in the composite. The analysis of deposit by X-ray gives the contents of 86% Ni and 4% P in the metalized composite. Similar observation has been reported earlier[12-14].

Figure 6 SEM images of un-plated composite and the electroless nickel coating on it图6 未镀覆的复合物及其上化学镀镍层的扫描电镜照片

4 Conclusion

A gongura (Hibiscus sabdariffa) fiber reinforced GP resin composite (green composite) was prepared. The tensile strength inferred that it can be used to make chairs, automotive components and other light weight applications. The metalized composite were prepared by electroless route as a trial method to enhance the mechanical properties of the composite.

[1] AGRAWAL R, SAXENA N S, SHARMA K B, et al. Activation energy and crystallization kinetics of untreated and treated oil palm fibre reinforced phenol formaldehyde composites [J]. Materials Science and Engineering A, 2000, 277 (1/2): 77-82.

[2] MISHRA S, MOHANTY A K, DRZAL L T, et al. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites [J]. Composites Science and Technology, 2003, 63 (10): 1377-1385.

[3] GU H. Tensile behaviours of the coir fibre and related composites after NaOH treatment [J]. Materials and Design, 2009, 30 (9): 3931-3934.

[4] NISHINO T, HIRAO K, KOTERA M, et al. Kenaf reinforced biodegradable composite [J]. Composites Science and Technology, 2003, 63 (9): 1281-1286.

[5] VALADEZ-GONZALEZ A, CERVANTES-UC J M, OLAYO R, et al. Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites [J]. Composites Part B: Engineering, 1999, 30 (3): 309-320.

[6] LI X, TABIL L G, PANIGRAHI S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review [J]. Journal of Polymers and the Environment, 2007, 15 (1): 25-33.

[7] YANG M C. Preparation of WC–Co based nanocomposite powders and alloy [D]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2004.

[8] MALLORY G O, HAJDU J B. Electroless Plating: Fundamentals and Applications [M]. Norwich: American Electroplaters and Surface Finishers Society, 1996.

[9] RUDNIK E, KOKOSZKA K, ŁAPSA J. Comparative studies on the electroless deposition of Ni–P, Co–P and their composites with SiC particles [J]. Surface and Coatings Technology, 2008, 202 (12): 2584-2590.

[10] LIU Y Y, YU J, HUANG H, et al. Synthesis and tribological behavior of electroless Ni–P–WC nanocomposite coatings [J]. Surface and Coatings Technology, 2007, 201 (16/17): 7246-7251.

[11] SARRET M, MÜLLER C, AMELL A. Electroless NiP micro- and nanocomposite coatings [J]. Surface and Coatings Technology, 2006, 201 (1/2): 389-395.

[12] WANG L Y, TU J P, CHEN W X, et al. Friction and wear behavior of electroless Ni-based CNT composite coatings [J]. Wear, 2003, 254 (12): 1289-1293.

[13] KARTHIKEYAN S, SRINIVASAN K N, VASUDEVAN T, et al. Studies on electroless Ni–P–SiO2and Ni–P–Cr2O3composite coatings [J]. Electroplating and Finishing, 2007, 26 (1): 1-7.

[14] KARTHIKEYAN, S, VENKATACHALAM G, SRINIVASAN K N, et al. Development of electroless Ni–P–BaSO4composite coatings [J]. Electroplating and Finishing, 2011, 30, (3): 31-34.

Mechanical properties of gongura fiber-reinforced general purpose resin composite and its metallization by electroless nickel plating process

Bharath Kota1, G. Venkatachalam1, S. Karthikeyan2,*, S. Narayanan3, C. Pandivelan3

( 1. Design Division, School of Mechanical and Building Sciences, VIT university, Vellore-632 014, India; 2. Materials Chemistry Division, School of Advanced Sciences, VIT university, Vellore-632 014, India; 3. Manufacturing Division, School of Mechanical and Building Sciences, VIT university, Vellore-632 014, India )

The gongura fiber was treated with 5% NaOH solution and then used to make a fiber-reinforced general purpose resin composite. The tensile behaviors of the composites prepared with different volume fractions of treated fibers were studied, indicating they have similar mechanical properties with traditional composites. The tensile strength of composite is increased with the increasing of fiber content. The microhardness of the composite metalized by electroless nickel plating process is 7 times greater than that of the pure composite.

gongura; general purpose resin; composite; electroless nickel plating; metallization; mechanics

TQ153.12

A

1004 – 227X (2011) 12 – 0029 – 03

1 Introduction

The dynamic climate change prevailing in someparts of southern Asia has reduced the seasonal crop agricultural activities and hence the farmers are forced to cultivate non-seasonal plants such as gongura (Hibiscus sabdariffa). The availability and mechanical properties of fiber made from this plant catch the attention of authors to focus on the processing and characterization of fiberreinforced composites made from gongura. Alkaline treatment is one of the most used chemical treatments for natural fibers and used to reinforce thermosets and thermoplastics. The important modification in this treatment is disruption of hydrogen bonding in the structure, causing the increase in surface roughness. Addition of aqueous sodium hydroxide (NaOH) to natural fiber promotes the ionization of hydroxyl group to alkoxide[1-2]. Moisture absorption and lack of adhesiveness with polymers are the major drawbacks with natural fiber. So fibers are undergone chemical treatment to overcome the above problems. The concentration of chemicals used for treatment also plays a role. Mishra et al[2]reported that 5% NaOH treated sisal fiber-reinforced polyester composite had better tensile strength than that prepared with 10% NaOH treated ones. This is because at higher alkali concentration, excess delignification of natural fiber occurs, resulting in a weaker or damaged fiber. The tensile strength of the composite decreased drastically after certain optimal NaOH concentration. There are many natural fiber reinforced composites reported in the literature. Their various properties like physical, thermal, mechanical etc. are studied under different fiber volumes. Huang[3]studied the tensile behavior of coir fiber made composite by treating the fiber with NaOH. Nishino et al[4]analyzed the tensile strength of kenaf fiber reinforced composites. It is reported that alkaline treatment has two effects on the fiber: (1) it increases surface roughness resulting in better mechanical interlocking; and (2) it increases the amount of cellulose exposed on the fiber surface, thus increasing the number of possible reaction sites[5]. In this paper, the gongura reinforced composite is subjected to electroless nickel coating to obtain metalized composite. The deposits were characterized by Vickers hardness measurement and SEM.

date:2011–05–08 Revised date: 2011–07–13

S. Karthikeyan, (E-mail) drskarthikeyanphd@gmail.com, skarthikeyanphd@yahoo.co.in.

Biography:Bharath Kota, male, 23 years old, a graduate engineer in M.Tech (CAD/CAM) from the School of Mechanical and Building Sciences (SMBS), VIT University, Vellore, Tamilnadu, India. He has presented numerous research papers in the field of finite element analysis, electroless plating, and composites in international conferences. His research interest includes preparation of nanocomposites and electroless deposition of metals.

[ 编辑:温靖邦 ]