Simulation of 1,3-Butadiene Production Process by Dimethylfomamide Extractive Distillation

2009-05-14YANGXiaojian杨小健YINXuan殷绚andOUYANGPingkai欧阳平凯

YANG Xiaojian (杨小健)*, YIN Xuan (殷绚) and OUYANG Pingkai (欧阳平凯)

Simulation of 1,3-Butadiene Production Process by Dimethylfomamide Extractive Distillation

YANG Xiaojian (杨小健)1,*, YIN Xuan (殷绚)1and OUYANG Pingkai (欧阳平凯)2

1Controlling Engineering Center, Nanjing University of Technology, Nanjing 210009, China2College of Life Science and Pharmaceutical Engineering, Nanjing University of Technology, Nanjing 210009, China

Nowadays, extractive distillation is the main technique to produce 1,3-butadiene. This study simulated the 1,3-butadiene production process with DMF extractive distillation by Aspen Plus. The solvent ratio is the most important parameter to the extractive distillation process. The article has given out the proper solvent ratios, reflux ratios, distillate ratios, and bottom product ratios of the columns. It also discusses the thermal loads of several columns. The results of simulation are consequently compared with the plant data, which shows good accordance with each other.

simulation, 1,3-butadiene, dimethylfomamide, extractive distillation

1 Introduction

Extractive distillation is the main technique to produce 1,3-butadiene, which is easy and cost-efficient. The extractive distillation methods can be separated into 3 kinds according to the extraction solvents, and they are acetonitrile (ACN) method, dimethylfomamide (DMF) method (also called GPB method), and-methyl-pyrrolidone (NMP) method [1]. The disadvantage of ACN method is the complexity to recover the solvent [2]. Furthermore, ACN is toxic to the environment [3], so its application is limited now. Dimethylfomamide is hypo-toxic, miscible with C4at any proportion, and it does not become azeotropic with any component in C4. The shortage is that an inhibitor should be added to prevent polymerization. Some materials might be hydrolyzed into formic acid and dimethylamine when there is water. And the hydrolysates are corrosive to carbon steel [4-7]. NMP has good selectivity and solubility, high boiling point, and low vapor pressure. The solvent is avirulent and biodegradable. The solvent loss is very low [8-10]. About 70% of the processes in China use DMF methods [3, 11]. Other newly developed methods for the production of butadiene are Houdry technology, oxydehydrogenation of-butylene, catalytic reaction of ethanol, and so on [12].

The demand for 1,3-butadiene in Asia increased by 3% in 2005, which came to 3.9 million tons. Between 2005-2010, the growth rate of 1,3-butadiene consumption in Asia will reach 4.1% per year [13]. The capacity and efficiency of 1,3-butadiene production in China is still much lower than that of other countries. The aim of this work is to study the DMF method by simulation, to improve production efficiency, and to optimize the operation conditions.

This simulation incorporates fundamental chemical engineering principles and advanced software tools for the DMF process. It includes mass and energy balances, thermodynamic parameters, phase equilibrium, and distillation modeling. Aspen Plus is used to simulate the processes [14, 15]. The thermodynamic method chosen is NRTL-RK. The rigorous multistage separation (RADFRAC) model has been used to calculate the distillation columns. All the calculations are based on mass. According to the characteristics of the real process, the process is separated into four sections.

2 DMF Process

The process uses GPB technology (industrialized in 1965 by Geon Company, Japan) to extract 1,3-butadiene from C4materials. The process contains two extractive distillation sections, one ordinary distillation section, and one solvent purification section, as shown in Fig. 1. In the first extractive distillation section, substances that have higher relative volatility compared with 1,3-butadiene in DMF are removed. In the secondary extractive distillation section, substances of lower relative volatility are removed. Only the substances whose boiling points differ far from 1,3-butandiene can be removed in the third section. The solvent purification section is used to purify and recover the solvent.

3 Process Data

This set of equipment is designed to treat 1.08×108kg·a-1C4material, and the production of 1,3-butadiene is 6.0×107kg·a-1. The equipment commonly runs under 50% of the design capacity. The running time is 7800 h·a-1. The C4feed to the plant is (14.0-18.0)×103kg·h-1. In the simulation, it is set to the average value of 16.0×103kg·h-1. There are four feeds to the whole process, one of C4, two of DMF, and one of--butylcatechol (TBC). The following are the conditions of the feeds under the typical operation condition.

Figure 1 DMF (GPB) process to produce 1,3-butadiene

3.1 C4 feed

Raw C4material includes butylenes, butanes, and some other impurities (C3, C5). The water content in C4material must be<500 mg·kg-1to prevent hydrolysis of DMF. 1,3-Butadiene content of C4material is generally between 45.0%-52.0% (by mass). Three typical compositions of the C4material are shown in Table 1.

Table 1 Main components of C4 material①

① Data source: Yangzi Petro-Chemical Plant, Sinopec.

3.2 Solvent (DMF) feed

The solvent contains 4.0% (by mass) tar and 96.0% (by mass) DMF. In the first extractive distillation column T1, the flow of solvent (DMF) is approximately 7-8 times than that of C4. Another solvent stream feeds the secondary extractive distillation column (T3), and the amount of solvent is 0.8-1.2 times that of C4feed in T1.

3.3 Polymerization inhibitor (TBC) feed

In order to prevent 1,3-butadiene polymerization, TBC is added in column T6 as the polymerization inhibitor [16]. The dosage is 0.003% (by mass) of the total feed in T6.

4 Thermodynamic Method and equations

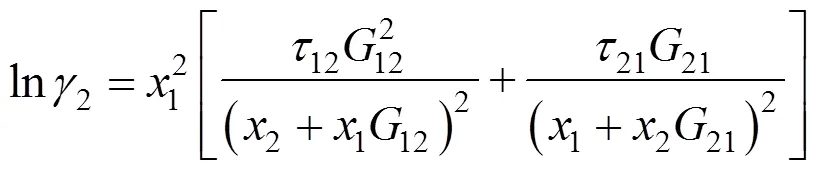

The thermodynamic method used in the simulation is NRTL-RK. Non-Random Two Liquids (NRTL) equations are suitable to describe the hydrocarbons and water. The NRTL activity coefficient equations for binary systems are:

Table 2 Parameter a12 in some binary systems

5 Simulation results

The simulations for different C4feeds are in good accordance with plant data. The following paragraphs choose a typical simulation to discuss the results.

5.1 First extractive distillation section

The first extraction distillation section includes two columns, T1 and T2. Because 1,3-butadiene is easy to dimerize and it is difficult to calculate the reaction during the whole process, F1 is added before T1 to calculate dimerization.

Figure 2 is the first extractive distillation section. T1 is the first extractive distillation column, including two feeds: C4and DMF. Components lighter than 1,3-butadiene are removed from the top, whereas 1,3-butadiene and heavier components are extracted by DMF at the bottom. T2 is a stripping column, the feed of which is the bottom discharge of T1. The function of T2 is to strip out hydrocarbons from DMF [18]. The hydrocarbons stripped out at T2 top are cooled to (35±5)°C by two stages of condenser, and then, sent to T3 by a compressor. The stream of hydrocarbons must be below 80°C and 0.6MPa to prevent polymerization. Streams after the compressor are recycled back in order to improve the efficiency of separation [19]. Table 3 shows the plant data, the plant demand, and the simulated results of this section.

Figure 2 Flow chart of the first extractive distillation section

Table 3 Comparison of the simulated results and the plant demand in the first section

Figure 3 Influences of solvent ratio upon the contents of several key components of T1

◆ 1,3-butadiene content in top products;□-2-butene content in bottom products; △-2-butene content in bottom products

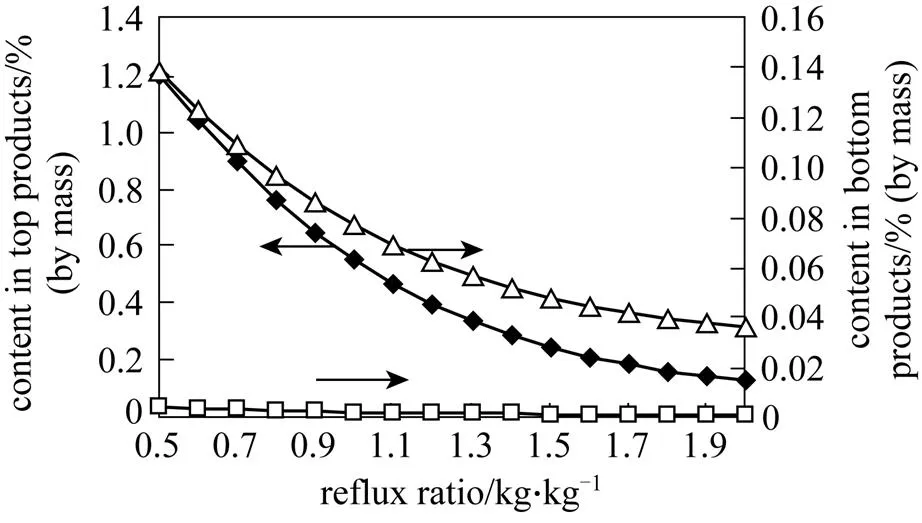

Figure 4 Influences of reflux ratio upon the contents of several key components of T1

◆ 1,3-butadiene content in top products;□-2-butene content in bottom products; △-2-butene content in bottom products

In the extractive distillation process, the solvent ratio is very important for the final results. Fig. 3 and Fig. 4 show the influences of the solvent ratio and the reflux ratio upon the performance of T1. It can be seen that larger solvent ratio and reflux ratio produce better separation results, while more energy will be consumed. So, there exists a minimal solvent ratio and a minimal reflux ratio to reach the plant demand [20]. From the simulation results, the minimal solvent ratio and the minimal reflux ratio of T1 are 7.5 kg·kg-1and 1.4 kg·kg-1, respectively.

Figure 5 Influences of feed plate upon the contents of several key components of T1

◆ 1,3-butadiene content in top products;□-2-butene content in bottom products; △-2-butene content in bottom products

Figure 6 Influence of distillate ratio upon the performances of T2

□ bottom temperature; △ 8th plate temperature; ◇ top temperature;■ heat duty of condenser

Figure 5 determines the best feed plate of T1. Dimethylfomamide is fed in the first plate. The best feed plate of C4is in the middle of the column, which is on the 39th theoretical plate. Fig. 6 shows the influence of distillate ratio on the top temperature, the bottom temperature, and the condenser heat duty of T2. T2 is a stripping column, which consumes large amount of heat. So proper operation conditions can help save a lot of energy. When the distillate ratio of T2 is more than 0.14 kg·kg-1, the temperatures of the column can meet the plant demand, but the condenser heat duty increases with the increase of the distillate ratio. Hence, the minimal distillate ratio is 0.14 kg·kg-1. The calculated bottom temperature is 161.75°C, which matched the measured temperature 161.76°C well.

5.2 Secondary extractive distillation section

The secondary extractive distillation section includes three columns, the extractive distillation column T3, the 1,3-butadiene recovery column T4, and the stripping column T5, as shown in Fig. 7. T3 has two feeds, the stripped top discharge of T2 and DMF. The feed of T3 contained 1,3-butadienen, vinylacetylene, 1-butyne, 1,2-butadiene, methyl-acetylene, and C5. The relative volatility of methyl-acetylene in DMF is close to 1,3-butadiene, which can not be removed in this section. The top discharge of T3 is mainly 1,3-butadiene with small amount of impurities, which is purified in the next section. The T3 bottom discharge DMF still contains much 1,3-butadiene. The bottom discharge of T3 is sent to T4 to recover 1,3-butadiene. The top discharge of T4 is 1,3-butadiene with some other hydrocarbons, which is recycled to the first section to keep mass balance. The bottom discharge of T4 is DMF dissolving some hydrocarbons, which is sent to T5 to recover DMF. Too large amounts of vinylacetylene might cause an explosion. When the vinylacetylene content exceeds 0.5 kg·kg-1in the top product of T5, it should be diluted by butane or butylene. Table 4 compares the simulated results of this section and the plant demands.

Figure 7 Flow chart of the secondary extractive distillation section

Three parameters might influence the bottom temperature of T3. They are the solvent ratio, the reflux ratio, and the distillate ratio. The solvent ratio means solvent feed: hydrocarbons feed, the reflux ratio means reflux flow: distillate, and the distillate ratio means distillate: hydrocarbons feed. Figs. 8-10 are the influences of these three parameters on the top and bottom temperatures, and the reboiler heat duty of column T3. The importance of the parameters is the following: distillate ratio>solvent ratio>reflux ratio. The calculated vinylacetylene content is far below the plant demand. The proper values of the parameters are the following: the solvent ratio 2.0 kg·kg-1, the flux ratio 1.0 kg·kg-1, and the distillate ratio 0.845 kg·kg-1. Although the distillate ratio influences the T3 performances more than the other two parameters, the most important parameter to control here is solvent ratio. Too low a solvent ratio might cause the distillate and the bottom flow-off specification. And when the solvent ratio is too high, it might induce waste of large amount of energy.

Figure 8 Influences of solvent ratio on the performances of T3

△ bottom temperature; ◇ top temperature; ■ heat duty of reboiler

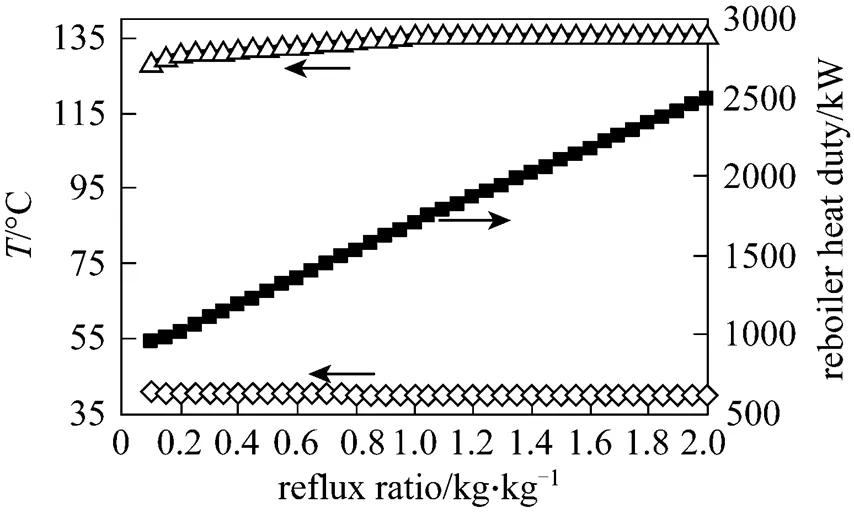

Figure 9 Influences of reflux ratio on the performances of T3

△ bottom temperature; ◇ top temperature; ■ heat duty of reboiler

Column T4 is very simple and is used to recover 1,3-butadiene from the solvent. Its top temperature is very steady. The bottom temperature increases slightly with the increase of the bottom product ratio.

Table 4 Comparison of the simulated results and the plant demand in the secondary section

Figure 10 Influences of distillate ratio on the performances of T3

△ bottom temperature; ◇ top temperature; ■ heat duty of reboiler

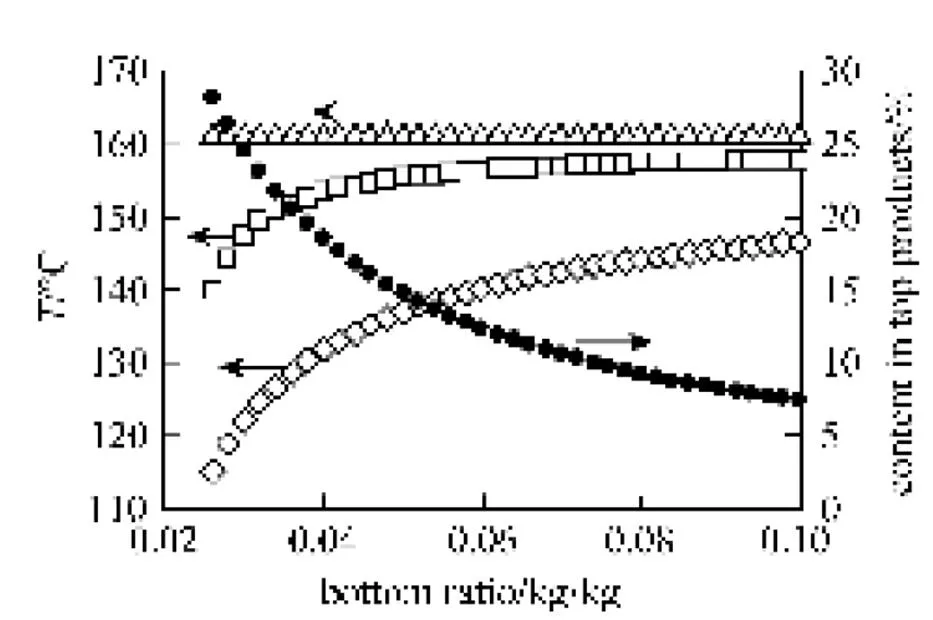

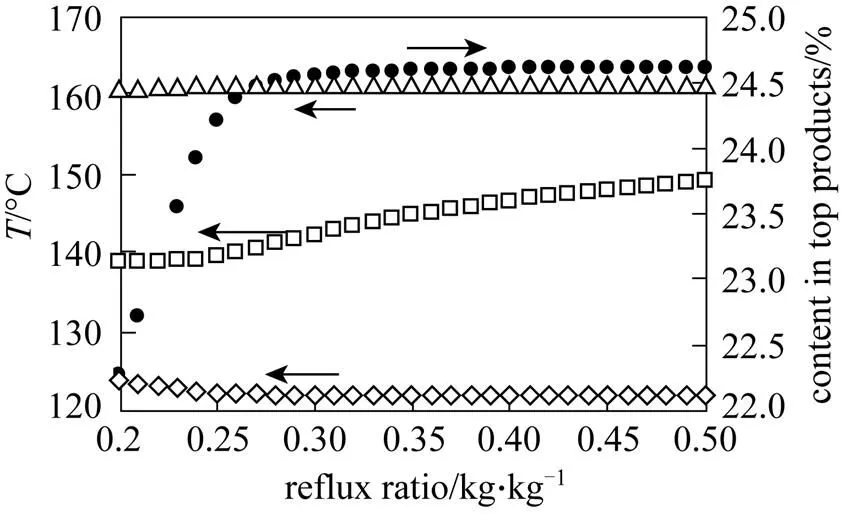

Figures 11 and 12 are the influences of the bottom product ratio, and the reflux ratio on the performances of T5. The bottom product ratio influences the bottom temperature of T5 more than the reflux ratio. In order to keep the temperature of the 12th plate above 147°C, the bottom product ratio, and the reflux ratio should be kept above 0.03 kg·kg-1and 0.42 kg·kg-1, respectively. The bottom product ratio influences the temperature of all the plates except that of the top one, and the reflux ratio can only adjust the temperature of the middle plates. The vinylacetylene content in top products decreases with the increase of the bottom product ratio and the reflux ratio. Hence, if one wants to reduce the vinylacetylene content and to control the temperature of the plates at some fixed value at the same time, the best way is to increase the bottom product ratio and to decrease the reflux ratio.

Figure 11 Influences of bottom product ratio on the performances of T5

△ bottom temperature; ◇ top temperature; □ 12th plate temperature;● vinyl acetylene content in top products

Figure 12 Influences of reflux ratio on the performances of T5

△ bottom temperature; ◇ top temperature;□ 12th plate temperature; ● vinyl acetylene content in top products

5.3 Ordinary distillation section

The ordinary distillation section is to remove the impurities, which can not be separated out in the previous sections. This is shown in Fig. 13. The methyl-acetylene and water can be removed by T6. The top pressure of T6 varies with the methyl-acetylene content and the cooling water temperature. The more the content of methyl-acetylene in the feed stream of T6, the more the loss of 1,3-butadiene in the distillate. The polymerization inhibitor TBC added in this section is to prevent the aggregation of 1,3-butadiene. The retained minor constituent of-2-butene, 1,2-butadiene 1-butyne, and C5are removed by T7. Table 5 compares the simulated results of this section and the plant demands.

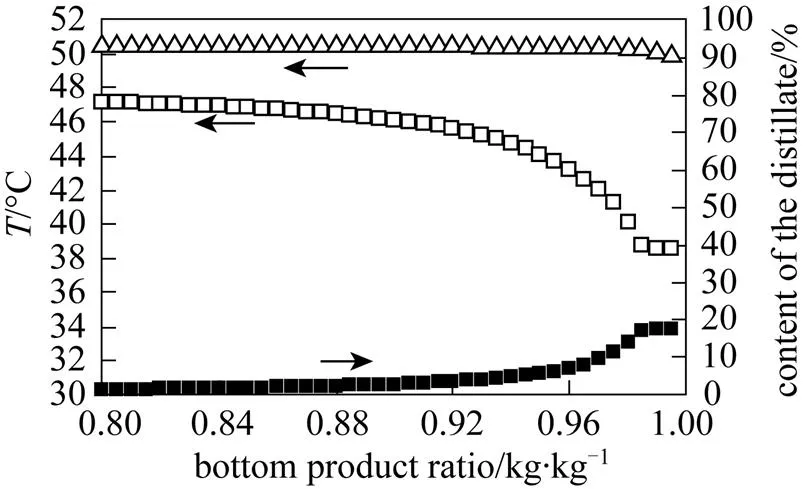

Figure 14 is the influence of bottom product ratio on the performances of T6. Fig. 15 is the influences of reflux ratio on the performances of T6. The bottom product ratio influences the performances of T6 more than other parameters. The T6 top temperature can meet the demand when the bottom product ratio is more than 0.91 kg·kg-1, but the best bottom product ratio is 0.98 kg·kg-1. The proper reflux ratio is 10 kg·kg-1. When the reflux ratio is more than 10 kg·kg-1, the 1,3-butadiene content is over the specification and the top temperature decreases only slightly. So the proper reflux ratio here is 10 kg·kg-1.

Figure 13 Flow chart of the secondary extractive distillation section

Table 5 Comparison of the simulated results and the plant demand in the secondary section

Figure 14 Influences of bottom product ratio on the performances of T6

△ bottom temperature;□ top temperature;■ methyl-acetylene content of the distillate

Figure 15 Influences of reflux ratio on the performances of T6

△ bottom temperature; □ top temperature;■ methyl-acetylene content of the distillate

Figure 16 is the influence of bottom product ratio upon the performance of T7. T7 is the secondary distillation column used to remove high boiling point materials, such as-2-butene, 1,2-butadiene, vinylacetylene, and so on. From Fig. 14, the suitable bottom product ratio is 0.026 kg·kg-1. When it is lower, the bottom temperature is too high, and the 1,3-butadiene content of the bottom product will exceed the specification.

Figure 16 Influences of bottom product ratio on the performances of T7

△ bottom temperature; ◆ 1,3-butadiene content of the distillate;■ 1,3-butadiene content of the bottom product

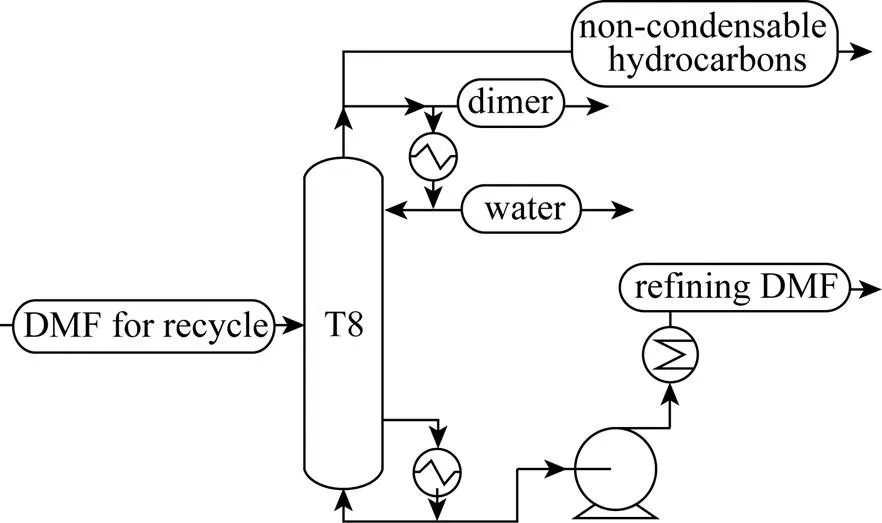

5.4 Solvent purification section

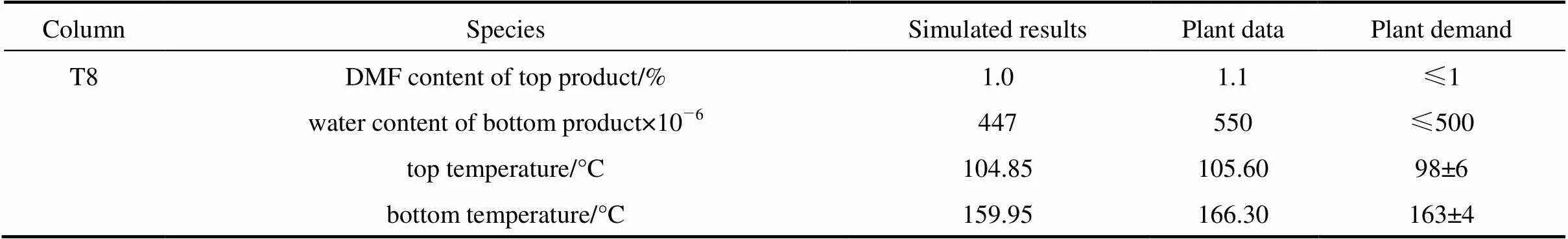

The solvent purification section is to refine and to reuse the solvent. There is only one column T8 in this section, which is to separate out such materials as water, dimer, and some hydrocarbons. The refined DMF is obtained at the bottom of T8. Table 6 compares the simulated results of this column and the plant demand.

Figure 17 Flow chart of the solvent purification section

Table 6 Comparison of the simulated results and the plant demand in the secondary section

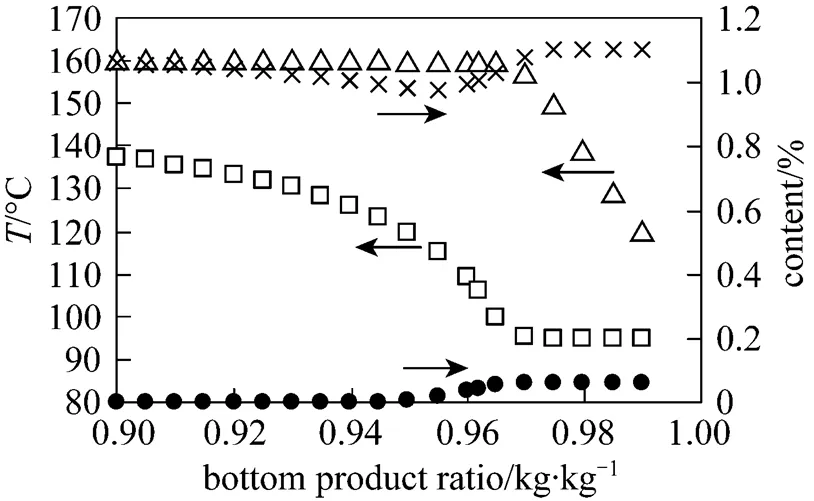

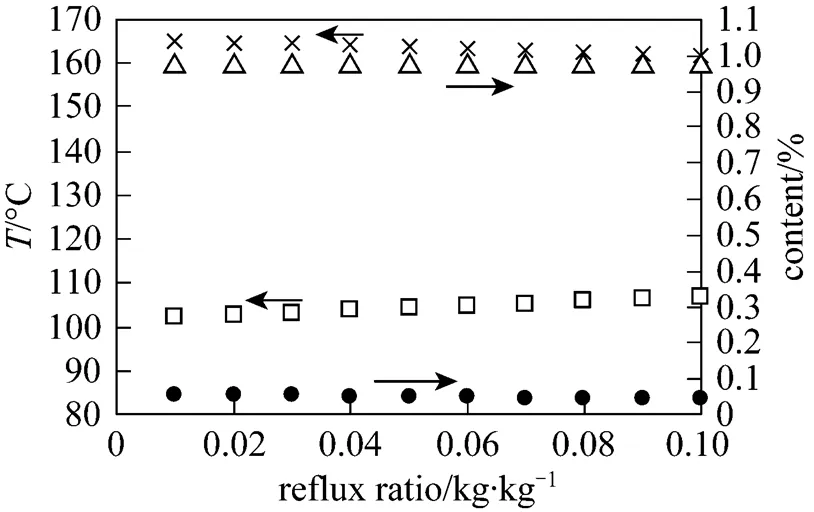

Figure 18 and Fig. 19 show the influence of reflux ratio and bottom flow ratio on the performance of T8. Fig. 18 shows that all the performances changed little by changing the reflux ratio. When the products can not meet the demand, the reflux ratio should be increased. The minimum reflux ratio here is 0.06 kg·kg-1. It can be seen from Fig. 19 that, if the DMF content of top product can be controlled above 1% (by mass), the suitable bottom product ratio should be in the range of 0.94-0.962 kg·kg-1. When the bottom product ratio is above 0.97 kg·kg-1, the top temperature and the bottom temperature decline greatly. And the separation result will be deteriorated.

Figure 18 Influences of reflux ratio on the performances of T8

△ bottom temperature;□ top temperature; × DMF content of top product;● water content of the bottom product

Figure 19 Influences of bottom product ratio on the performances of T8

△ bottom temperature;□ top temperature; × DMF content of top product;● water content of the bottom product

6 Conclusions

This study simulated the 1,3-butadiene production process with DMF extractive distillation method by Aspen Plus. The thermodynamic equations used here are NRTL equations, and the method chosen in the software is NRTL-RK. The whole process contains 8 columns, which are separated into 4 sections for simulation. The calculated results show good accordance with the plant data.

The discussion includes the influences of the operations upon the performances of the columns. The solvent ratio is the most important parameter to the extractive distillation process. The simulation studied the best solvent ratios. T1 and T3 are extractive distillation columns, and the best solvent ratios of T1 and T3 are 7.5 kg·kg-1and 2.0 kg·kg-1. T2 and T5 are stripping columns. When fixing the reflux ratio, energy consumption must be considered. The least reflux ratios of T2 and T5 are 0.14 kg·kg-1and 0.42 kg·kg-1, respectively. When something goes wrong with these two columns, increasing the reflux ratio properly will stabilize the column. T6 and T7 are distillation columns. They are used to purify the product 1,3-butadiene. The bottom product ratio of T6 should be kept above 0.91 kg·kg-1, and the best result is 0.98 kg·kg-1. The bottom product ratio of T7 should be more than 0.026 kg·kg-1. T8 is to recycle DMF. Its least reflux ratio is 0.06 kg·kg-1, and the proper bottom product ratio should be controlled within the range of 0.94-0.962 kg·kg-1.

The simulated results show that proper parameters will make productions meet the demands and save large amount of energy. The study gives us a clear understanding of the whole process and provides methods to adjust the process when it is unstable.

AcknowledgEments

,..,..

1 Li, Y.F., Wu, X.M., “Production and market of butadiene”,.. (China), 7 (6), 50-56 (2005).

2 Lei, Z.G., Wang, H.Y., Zhou, R.Q., Duan, Z.T., “Solvent improvement for separating C4with CAN”,.., 26, 1213-1221 (2002).

3 Zhao, Z.W., Yu, Q.N., “Comparison of some butadiene extraction technologies”,. (), 4, 11-19 (2005).

4 Takao, S., “DMF: newst butadiene solvent”,.., 45, 151-154 (1966).

5 Takao, S., “DMF can efficiently recover butadiene and isoprene”,, 77, 81-82 (1979).

6 Arakawa, M., Yoshioka, H., Nakazawa, K., “Process for producing 1,3-butadiene”, US Pat., 4504692 (1985).

7 Ogura, S., Soumai, M., “Process for separating highly pure butane-1 or butane-1/isobutene mixture from C4hydrocarbon fraction”, US Pat., 4555312 (1985).

8 Linder, A., Klaus, B.R., Ulrich, V.F., “Isolation of 1,3-butadiene from a C4-hydrocarbon mixture”, US Pat., 4277314 (1981).

9 Kaibel, G., Hefner, W., Keller, P., “Isolation of 1,3-butadiene”, US Pat., 4859286 (1989).

10 Klaus, Kindler, H., Hubert Puhl, L., “Method for separating a C4-hydrocarbon mixture”, US Pat., US6337429B1 (2002).

11 Lei, Z.G., Zhou, R.Q., Duan, Z.T., “Process improvement on separating C4by extractive distillation”,..., 85, 379-386 (2002).

12 Zhao, Y.Z., Zhang, L.B., Wang, J., “Development situation analysis of butadiene”,(), 14 (1), 57-61 (2004). (in Chinese)

13 Wu, J.P., “Increasing of 1,3-butadiene requirement in Asia”,... (), 6, 7-17 (2006). (in Chinese)

14 Ongiro, A., Ugursal, V.I., Taweel, A.M.A., Lajeunesse, G., “Thermodynamic simulation and evaluation of a stream chp plant using Aspen Plus”,..., 16 (3), 263-271 (1996).

15 Aotudeh-Gharebaagh, R., Legros, R., Chaouki, J., Paris, J., “Simulation of circulation fluidized bed reactors using Aspen Plus”,, 77 (4), 327-337 (1998).

16 Song, X.J., “Optimizing butadiene device to increase economic benefit”,.. (), 124 (1), 51-54 (2006). (in Chinese)

17 Renon, H., Prausnitz, J.M., “Local compositions in thermodynamic excess function for liquid mixtures”,., 14, 135 (1968).

18 Wang, W.H., Ren, W.H, Xu, W.Y., Yu, L.X., “Progress in separation of C4alkanes and alkenes by extractive rectification”,.. (), 28 (2), 20-23 (1999). (in Chinese)

19 Zhou, T., Gong, J.Z., Zhao, D.Z., “Analysis of the cause of influencing butadiene device run period”,(), 33 (12), 711-713 (2004). (in Chinese)

20 Li, S.J., Qian, F., “Operation condition optimization of butadiene extraction distillation column”,...., 32 (5), 591-595 (2006). (in Chinese)

2008-04-28,

2008-11-12.

* To whom correspondence should be addressed. E-mail: yxj_cec@126.com

猜你喜欢

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Modeling and Optimization for Scheduling of Chemical Batch Processes*

- Simulation of Droplet-gas Flow in the Effervescent Atomization Spray with an Impinging Plate*

- Numerical Investigation of Constructal Distributors with Different Configurations*

- The Kinetics of the Esterification of Free Fatty Acids in Waste Cooking Oil Using Fe2(SO4)3/C Catalyst

- Multiple Model Soft Sensor Based on Affinity Propagation, Gaussian Process and Bayesian Committee Machine*

- Measurement and Correlation of Solid-Liquid Equilibria of Phenyl Salicylate with C4 Alcohols