A Pragmatic Approach for Assessing the Economic Performance of Model Predictive Control Systems and Its Industrial Application*

2009-05-12ZHAOChao赵超SUHongye苏宏业GUYong古勇andCHUJian褚建

ZHAO Chao (赵超), SU Hongye (苏宏业), GU Yong (古勇) and CHU Jian (褚建)

A Pragmatic Approach for Assessing the Economic Performance of Model Predictive Control Systems and Its Industrial Application*

ZHAO Chao (赵超), SU Hongye (苏宏业)**, GU Yong (古勇) and CHU Jian (褚建)

State Key Laboratory of Industrial Control Technology, Institute of Cyber-Systems and Control, Zhejiang Univers ity, Hangzhou 310027, China

In this article, an approach for economic performance assessment of model predictive control (MPC) system is presented. The method builds on steady-state economic optimization techniques and uses the linear quadratic Gaussian (LQG) benchmark other than conventional minimum variance control (MVC) to estimate the potential of reduction in variance. The LQG control is a more practical performance benchmark compared to MVC for performance assessment since it considers input variance and output variance, and it thus provides a desired basis for determining the theoretical maximum economic benefit potential arising from variability reduction. Combining the LQG benchmark directly with benefit potential of MPC control system, both the economic benefit and the optimal operation condition can be obtained by solving the economic optimization problem. The proposed algorithm is illustrated by simulated example as well as application to economic performance assessment of an industrial model predictive control system.

economic performance assessment, model predictive control, linear quadratic Gaussian benchmark, steady-state model based optimization

1 INTRODUCTION

With a widespread implementation of model predictive control strategies in the chemical and petrochemical plants in the last two decades, industries have an increasing need to have a tool to reliably assessing the economic performance of model predictive control (MPC) applications [1]. A general approach for economic performance evaluation is to reduce the variance in the controlled variable, which in turn shifts the process mean closer to the operating constraint without increasing the frequency of constraint violation. This operation is referred to as the improved control operation as shown in Fig.1. Thus, the economic benefit is realized from operation at this new mean value [2]. Recently, a group of variance-based performance assessment techniques have been proposed in the literature.

The notable work has been done by Martin. [3], where a general framework for economic justification of advanced process control applications is given. Using statistical analysis, an approach for analysis of variance reduction under various improved control operations is developed in a study by Muske [4]. Considering the probability constraints for the quality process variables, Zhou and Forbes [5] proposed a structured procedure for economic benefits analysis using stochastic programming. According to steady-state model and backoff idea, an economic performance assessment of MPC control systems using a linear matrix inequality approach has been developed [6].

Decreasing the variability of the process variable is a principle way of quantifying the potential economic benefits of existing control systems due to improved control operation [2]. The achievable variance reduction in process control largely depends on the selected benchmark (or optimal control). Most of the existing performance assessment methods are concerned with variance reduction estimation with minimum variance control (MVC) as the benchmark. However, MVC is usually not a desired control strategy in most practical situations since it demands excessive control action and does not account for the constraints on the process variables [7]. Thus, MVC is no longer a suitable benchmark for performance assessment of MPC control systems, where the constraint handling and economic optimization are the main objectives [8]. Consequently, variance reduction estimation based on the MVC benchmark tends to obtain an unrealistic or overaggressive economic performance assessment for a practical MPC control system. The linear quadratic Gaussian (LQG) benchmark is an alternative benchmark, which has been proven to be a more realistic one than MVC when evaluating process control system with constraints since it considers input and output variances [9].

Figure 1 Economic improvement due to variability reduction

Making use of LQG benchmark, a new approach based on the model-based optimization scheme is presented in this study to provide a more flexible way to evaluate the economic performance for the MPC control systems. We also demonstrate practical applicability of the proposed approachsimulated example as well as through case study on an industrial MPC application.

2 LINEAR QUADRATIC GAUSSIAN BENCHMARK

MVC appears not to be appropriate for performance assessment of constraint control systems such as MPC applications since MVC does not explicitly take the control cost into account and is rarely implemented in practical situation. The LQG benchmark as an alternative benchmark has been proposed for performance assessment of control system with consideration of the control action constraints. Using LQG benchmark, the achievable performance is given by a trade-off curve as shown in Fig. 2, and this curve can be obtained by solving the LQG problem [9]. The LQG objective function is defined as follows:

The calculation of the LQG benchmark is briefly reviewed in this section following the approach of the study by Huang [10].

Figure 2 Optimal performance curve obtained through LQG benchmark

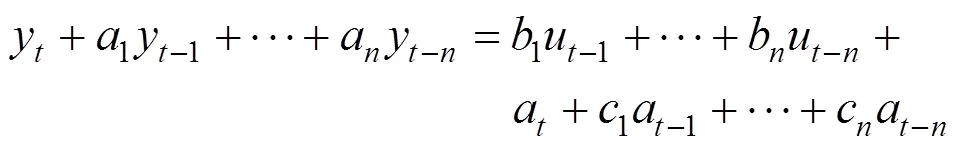

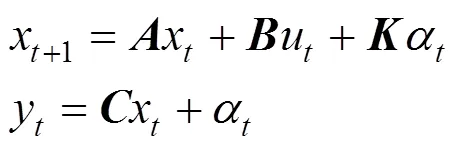

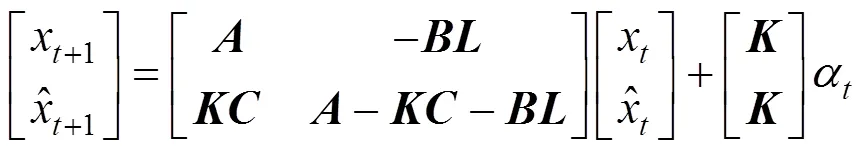

Consider that the process is framed in an autoregressive moving average model with exogenous input (ARMAX) expression:

The corresponding Kalman predictor can be written as

The optimal feedback control can be written as

whereis the optimal state feedback control gain and which can be solvedMATLAB LQ function. Combining the Kalman predictor with state feedback yields

Writing it in a compact form

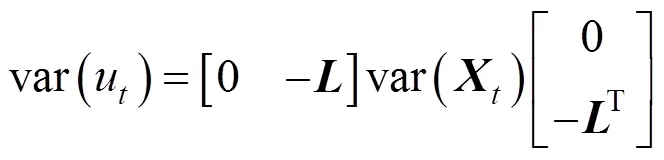

The variance of the input and output can be written as:

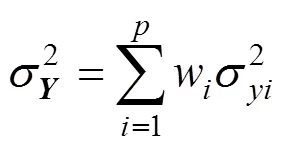

For the multi-input multi-output (MIMO) system, the objective function of LQG control is written as

3 ECONOMIC PERFORMANCE ASSESSMENT WITH MODEL-BASED OPTIMIZATION

Reduction of the variance of quality variables is identified as a key aspect in any attempt to increase benefit potential, but just reducing the variability is not always sufficient for economic benefit estimation because of the effect of the disturbance and the uncertainty parameters in the control system, which could degenerate the operation performance in most cases [5, 11-13]. Backoff approach has been proven to be an effective way to deal with disturbance and uncertainty in the control systems and has been widely used in the optimal control and design [14-18]. Model-based optimization strategy provides a very flexible way to incorporate the effect of disturbance into the computation of the optimal and feasible operation point, and economic potential may be realized from this new operation point.

Based on the idea of backoff approach and the steady-state optimization techniques in MPC solution, Zhou and Forbes [5] proposed a variance-based approach to evaluate the economic performance of existing run-time MPC application, where the steady-state performance estimation problem is posed in a constrained optimization form. Only the economic potential analysis is described here for the sake of brevity, and mathematical details can be found in the study by Xu[6].

subject to

4 ECONOMIC PERFORMANCE ASSESSMENT WITH LQG BENCHMARK

There are two important problems that should be taken into account while assessing the economic performance of process control systems. One is how to determine the relationship between economic performance and process variance reduction, and the other is the relationship between the input variance and the output variance. As remarked earlier, the model-based optimization technique can easily incorporate the backoff strategy into the optimization problem which thus provides a feasible solution to determine the relationship between economic performance and variance reduction. Based on the backoff approach and the steady-state model, the most economically attractive operating point, or the optimal operating point is determinedthe solution of a steady-state optimization problem with specified allowable constraint limit violation, and thus the economic benefit is realized from this new operation point.

The second issue can be considered an optimal control problem that determines the relationship between input variance and output variance. Xu. [6] solved this problem by using minimum energy covariance control. However, under the minimum energy covariance control, the relationship between input variance and output variance is not uniquely determined (.. an inequality relation rather than an equality relation). To this end, we consider a limit of control performance curve, represented by the LQG trade-off curve. Several possible optimal benchmark controls have been identified from the trade-off curve shown in Fig. 3, and each of them serves for a different control objective [19]. For example, the minimum energy controller is optimal in the sense that it offers minimum possible control effort and indicates the maximum variance reduction of control action (MV). Minimum variance control offers minimum possible error and the maximum variance reduction of output variable [controlled variable (CV)]. While a LQG trade-off controller has performance between the minimum variance control and minimum cost control, it offers a tradeoff between reduction of the output variance and the control action. Thus, LQG tradeoff control is a more realistic benchmark to estimate the process variance for constraint process control systems such as MPC application. In this study, the LQG benchmark is combined directly with benefit potential, which therefore leads to an achievable optimal benefit potential for MPC control system.

Figure 3 Performance assessment benchmark with different control objectives

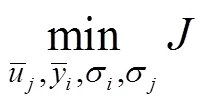

Given a process control system, the purpose of economic performance assessment can be now viewed as identifying the possibility of moving its operating point as close as possible to its optimal operating point consider likely disturbance and uncertainty. Given sufficient operating data, the base case operation can be described as its current mean values and standard deviations. The optimal operation condition can be obtained by solving the economic steady-state optimization problem with respect to the current constraint limit settings and the input and output variability relation described by the LQG tradeoff curve. Generally, a reasonable percentage of constraint limit violation of controlled variables (CVs), say 5%, is allowed such that 95% of operation falls within the range of±2 times standard deviation [3]. Since manipulated variables usually represent the valve position of actuator or the rotation speed of a motor, constraint violation is not allowed in practice. Therefore, a more conservative backoff strategy is implemented on MVs than on CVs, and ±3 times standard deviation is used for the analysis. Economic benefit potential can be determined by comparing optimal operation with base case operation. Based on the preceding analysis, the problem formulation of optimal operation is described as follows.

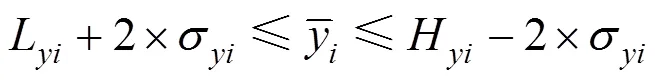

Considering the allowable percentage of violation of constraints, the following inequalities must be satisfied:

Based on above analysis, the economic optimization problem for the benefit potential assessment of MPC control system under different scenarios can be transferred to the following form:

Comparing the proposed assessing method with that presented in the study by Xu. [6], the major difference is that the established optimizer could simultaneously solve the optimal operation point and the corresponding variability changes for process variables since the LQG trade-off curve as the equality constraints are directly introduced into the economic performance determination problems. Further, the proposed procedure avoids the difficulty in determining the standard deviations of manipulated variables by solution of the optimal control problem, which thus requires less computational load. As a result, presented approach could provide a more simple and flexible way to evaluate the achievable economic performance of the MPC control systems.

5 CASE STUDY

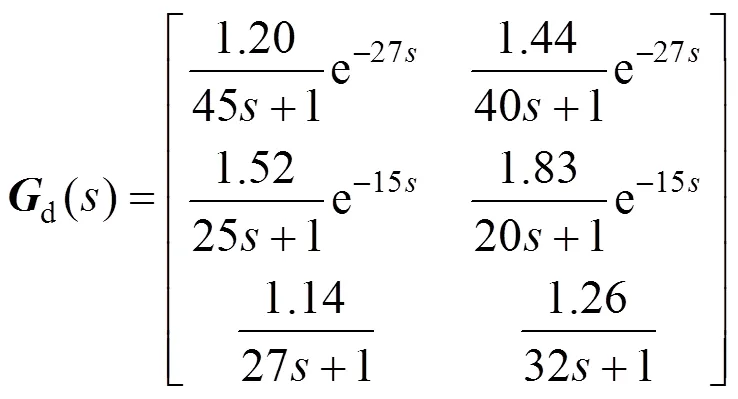

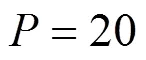

In this section, a simulation example is performed to demonstrate the effectiveness of the proposed approach in assessing the economic performance of MPC control system. The heavy oil fractionator of the Shell standard control problem as a benchmark process has been studied by many researchers [6, 20, 21]. The schematic diagram is shown in Fig. 4, and the transfer functions are displayed in Eqs. (29) and (30). The process has three controlled variables, three manipulated variables, and two disturbance variables. The manipulated variables are top draw (1), side draw (2), and bottom reflux (3); the controlled variables are top end point (1), side end point (2), and bottom reflux temperature (3); two disturbance variables are upper reflux (1) and lower reflux (2).

subject to

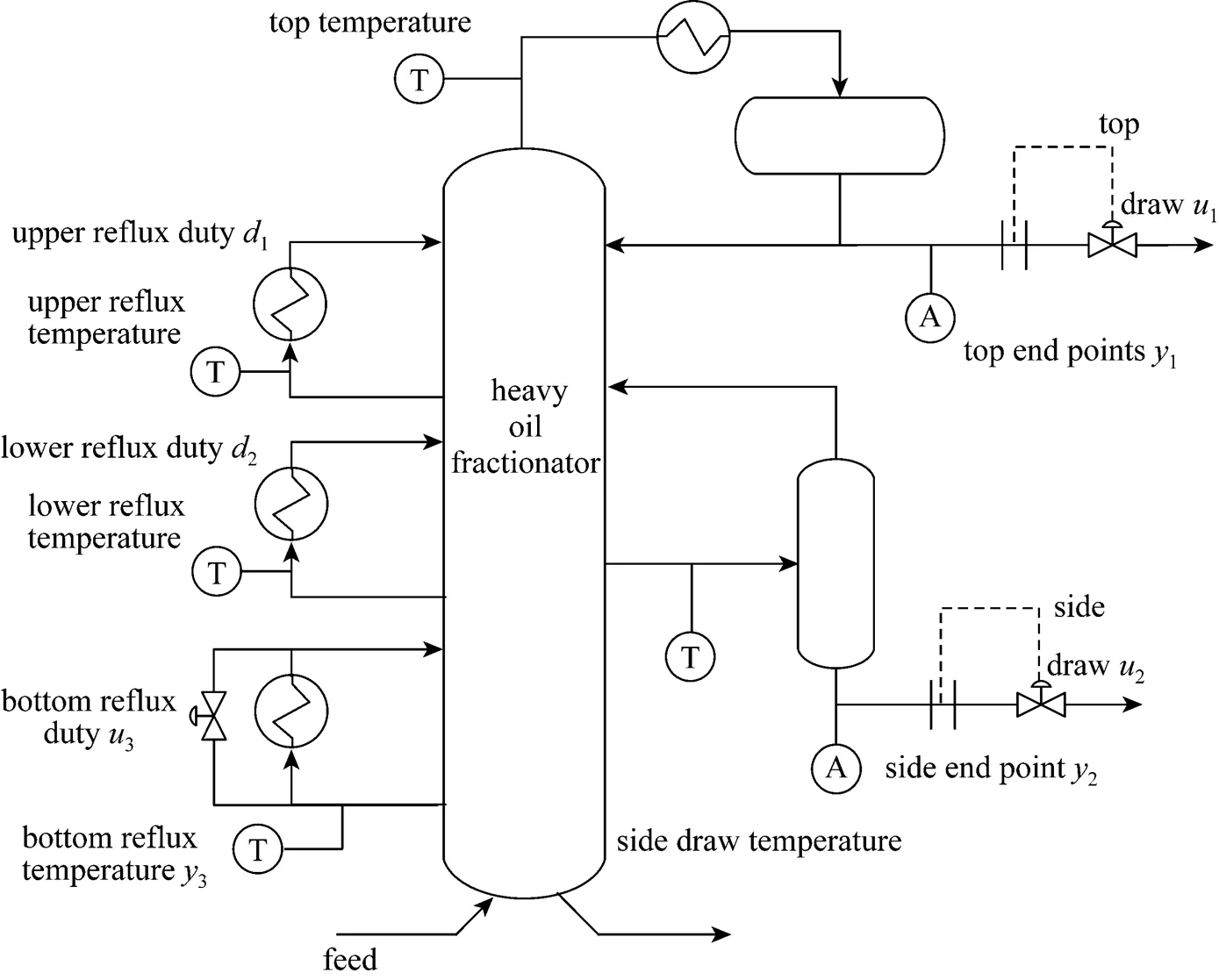

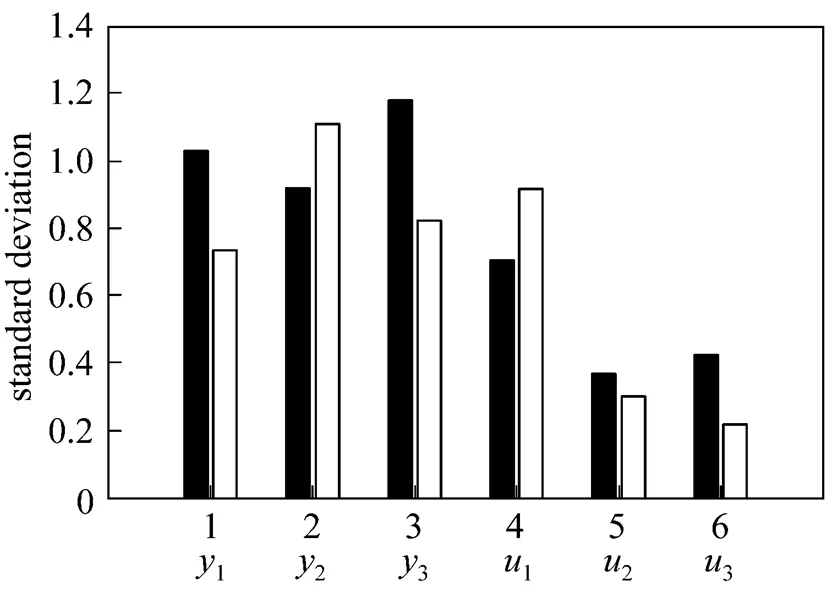

By simulation on this MPC application, a set of 3000 samples are extracted from the base case operation with given constraints limits is shown in Fig. 5. It should be noted that, there is no systematic method to effectively and quickly determine the MPC controller parameters such as prediction and control horizon, while ensuring good performance for MIMO systems. Consequently, selecting appropriate parameters is a very time-consuming part of an MPC design, and comprehensive knowledge of the process is required [23].

Figure 4 Process flow sheet of the heavy oil fractionation

The calculated benefit potentials can be verified by setting the optimal operating point obtained in different cases as the set point for corresponding low-level regulatory control loop with appropriate control upgrading. The realized benefit potentials are also listed in Table 1. For the existing variability scenario, the verified potential is approximately 84.4% of calculated one. This indicates that the calculated existing benefit potential is indeed achieved in practice. The achieved benefit potential is verified as 0.223 by reducing the variability of process variables by adjusting the weight coefficient matrices in MPC, and it is also close to that of calculated one. Fig. 7 presents a typical simulation result for output1under the base case and the variability reduction case operation. With the variance reduction of the1by increasing the corresponding elements in the matrix, the mean operating value is shift closer to its upper constraint limit, and thus give rises to increased economic benefit. Previous analysis and results once again show that realized economic potentials agree with the calculated ones, which demonstrates the feasibility of the proposed approach for economic performance assessment of MPC control systems.

Figure 5 Base case operation of simulated control process

Table 1 Results of heavy oil fractionation

Figure 6 Standard deviation of the base and optimal operation conditions

Figure 7 Simulation result under the base and optimal operation conditions

Figure 8 Process flow sheet of the xylenes distillation unit

DV1—feed flow (from bottom product in benzene column); DV2—feed temperature (for feed from exchanger in-xylene section); DV3—feed temperature (for feed from bottom product in benzene column)

6 INDUSTRIAL APPLICATION

Xylenes fractionation unit operation is important to ensure the proper functioning of PX unit with good operation performance. To achieve operational efficiency in terms of product costs, stable and reduced variance product composition, a multivariable MPC controller was designed and implemented on the xylenes fractionation unit at a petrochemical plant in China. The fractionation unit mainly consists of xylenes column, reflux drum, and heat furnace, where raw material is separated into the main product, xylene and other by-products. A schematic of the process flow sheet is shown in Fig. 8. The bottom products from upstream benzene column and the recycled stream, which all composed of heavier aromatic hydrocarbon (more than C7), are fed to the middle section of xylenes column. In the xylene column, the light components (mainly xylene) are distillated in the overhead, part of top products as the reflux are fed to reflux drum, and the reminder are back to raw buffer tank for feeding PX section. The bottom product, as heavier components (more than C9), are fed to OX column for further separation. The product specification for product is that the concentration of the xylene in the top product has to be kept above 97.5%.

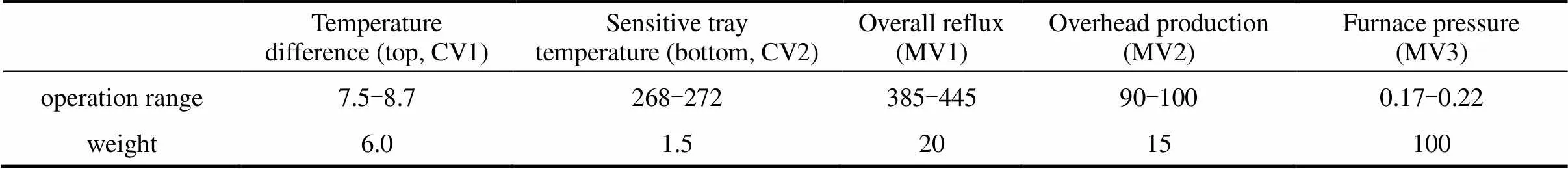

The product purity is of main concern in the normal operation of this distillation unit, and the temperature can be used as a qualitative index in control scheme to ensure product quality, since the distillate and bottoms streams compositions can be inferred by measuring the temperatures of trays near each end of the column [22]. Thus, the temperature difference (top) and the sensitive tray temperature (bottom) are used as controlled variables, and the furnace fuel pressure, overall reflux, and overhead production as manipulated variables are adjusted to keep the above controlled variables satisfying their operation constraints. The feeding fluctuation and feed temperatures are the main disturbances to this unit, and they constantly force column operation to take high reflux ratio to keep quality variable (top product) within specification limits, which thus results in decrease in the top product. The process model() and disturbance model() are identified through identification experiment and are given in Eqs. (32) and (33) in the form of continuous transfer matrices, respectively. The implementation MPC structure is shown in Fig. 9, and a list of controlled, manipulated and disturbance variables and the corresponding engineering constraints with weights are given in Table 2.

The operating data for the two controlled variables and three manipulated variables with the existing MPC controller under normal operation condition is shown in Fig. 9. These data consist of 30s samples over one 56-h operating period. Now the proposed approach is used to evaluate the economic potential resulted from the improved control in this unit.

Figure 9 Base operation data for xylenes distillation unit

Table 2 MVs, CVs and their engineering range, weights in MPC

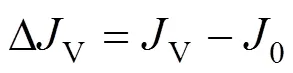

Figure 10 Economic performance under different operation conditions

1—ideal (0.753); 2—existing (0.091); 3—reducing (0.351)

Figure 11 Performance indices of distillation process

1—existing performance index; 2—maximum attainable performance index

As previous remark, the product specification is the main concern and distillation process takes “precise” control strategy, so given engineering range of CVs and MVs are rather narrow. For the existing variability scenario, only small move is permitted for operating point adjusting, otherwise which may result in MV saturation or CV violation of their constraint limits, and thus off-specification product would be distillated. The best economic performance index indicates that the capacity or room for benefit improvement increased significantly while actual variability decreased within the engineering range. This gives the guideline for carrying out the further regulatory task. Therefore, the proposed approach should promote more extensive industrial applications of economic performance assessment technology.

7 CONCLUSIONS

An economic performance assessment algorithm based on the LQG benchmark is developed to assess the economic potentials of MPC control system in this study. LQG benchmark offers a more realistic trade-off between the variability reduction on the output and the input variables. Based on the LQG benchmark as well as backoff strategy, the economic performance assessment problems under different scenarios are described in the form of constrained optimization problems. The proposed approach provides a simple way to estimate the economic potential as well as the optimal operation condition by directly solving a quadratic optimization problem, and the resultant optimal operating point can be sent to regular control system as the optimal target point for realization of benefit improvement. The utility of the proposed method in the economic performance assessment of MPC control system is demonstrated through the case study as well as an industrial MPC application.

NOMENCLATURE

a,aquadratic coefficient of theth output and theth input variable.

b,blinear coefficient of theth output and theth input variable

H,Hhigh limit of theth output and theth input variable

the steady-state process gain

L,Llower limit of theth output and theth input variable

(),() the nominal process model and the disturbance model

r,rthe user-defined percentage of relaxation in the limit forth output andth input variable

di,djtarget value of theth output and theth input variable

hoi,hojthe variable moves of theth output and theth input variable

σ,σstandard deviation of theth output and theth input variable

1 Bauer, M., Craig, I.K., “Economic assessment of advanced process control—A survey and framework”,., 18, 2-18 (2008).

2 Edgar, T.F., “Control and operations: When does controllability equal profitability?”,..., 29, 41-49 (2004).

3 Martin, G.D., Turpin, L.E., Cline, R.P., “Estimating control function benefits”,., 69, 68-73 (1991).

4 Muske, K.B., “Estimation the economic benefit from improved process control”,...., 42, 4535-4544 (2003).

5 Zhou, Y., Forbes, J.F., “Determining controller benefitsprobabilistic optimization”,...., 17, 553-568 (2003).

6 Xu, F., Huang, B., Akande, S., “Performance assessment of model predictive control for variability and constraint tuning”,...., 46, 1208-1219 (2007).

7 Huang, B., Edgar, C.T., “Model validation for industrial model predictive control systems”,..., 55, 2315-2327 (2000).

8 Ko, B.S., Edgar, T.F., “Performance assessment of constrained model predictive control systems”,., 47 (6), 1363-1371 (2001).

9 Boyd, S., Barratt, C., Linear Control Design, Prentice Hall, New Jersey (1991).

10 Huang, B., Shah, S.L., Performance Assessment of Control Loops: Theory and Applications, Springer, New York (1999).

11 Cutler, C.R., Perry, R.T., “Real time optimization with multivariable control is required to maximize profits”,..., 7, 663-667 (1983).

12 Contreras, J.L., Marlin, T.E., “Control design for increased profit”,..., 24, 267-272 (2000).

13 Loeblein, C., Perkins, J.D., “Structural design for on-line process optimization (1) Dynamic economics of MPC”,., 45 (4), 1018-1029 (1999).

14 Babri, P.A., Bandoni, J.A., Barton, G.W., Romagnoli, J.A., “Back-off calculations in optimizing control: A dynamic approach”,..., 19, 699-708 (1995).

15 Figueroa, J.L., Babri, P.A., Bandoni, J.A., Romagnoli, J.A., “Economic impact of disturbance and uncertainty parameters in chemical process—A dynamic back-off analysis”,..., 20, 453-461 (1996).

16 Narraway, L.T., Perkins, J.D., Barton, G.W., “Interaction between process design and process control: Economic analysis of process dynamic”,.., 1, 243-250 (1991).

17 Young, J.C.C., Swartz, C.L.E., Ross, R., “On the effects of constraints, economics and uncertain disturbances on dynamicoperability assessment”,..., 20, 667-682 (1996).

18 Loeblein, C., Perkins, J.D., “Economic analysis of different structures of on-line process optimization systems”,..., 22, 1257-1269 (1998).

19 Huang, B., “Pragmatic approach towards assessment of control loop performance”,...., 17, 589-608 (2003).

20 Kassmann, D.E., Badgwell, T.A., “Robust steady state target calculation for model predictive control”,., 46 (5), 1007-1024 (2000).

21 Ying, C.M., Joseph, B., “Performance and stability analysis of LP-MPC and QP-MPC cascade control system”,., 45 (7), 1521-1534, (1999).

22 Bequette, W.B., Process Control: Modeling, Design and Simulation, Prentice Hall, New Jersy (2003).

23 Rossiter, J.A., Model-based Predictive Control: A Practical Approach, CRC Press, USA (2003).

2008-01-07,

2008-12-24.

the National Creative Research Groups Science Foundation of China (60421002) and National Basic Research Program of China (2007CB714000).

** To whom correspondence should be addressed. E-mail: hysu@iipc.zju.edu.cn

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Design and Performance Analysis of Micro Proton Exchange Membrane Fuel Cells*

- Isolation of Cordyceps ophioglossoides L2 from Fruit Body and Optimization of Fermentation Conditions for Its Mycelial Growth*

- Efficient and Comprehensive Utilization of Hemicellulose in the Corn Stover*

- Simulating Surface Aeration Systems at Different Scale of Mixing Time*

- Kinetics of Reaction-Crystallization of Struvite in the Continuous Draft Tube Magma Type Crystallizers—Influence of Different Internal Hydrodynamics

- Preparation and Characterization of Tungsten-substituted Molybdophosphoric Acids and Catalytic Cyclodehydration of 1,4-Butanediol to Tetrahydrofuran*