Trajectory Optimization and Motion Simulation of a Flexible Polishing Industrial Robot for Watchcases

2021-06-22YANGJingjing杨晶晶JINXiaoyi金晓怡XIETengxiao谢腾骁XIYing

YANG Jingjing(杨晶晶), JIN Xiaoyi(金晓怡)*, XIE Tengxiao(谢腾骁), XI Ying(奚 鹰)

1 School of Mechanical and Automotive Engineering, Shanghai University of Engineering Science, Shanghai 201620, China

2 College of Mechanical Engineering, Tongji University, Shanghai 201802, China

Abstract: To optimize the working time of the flexible polishing industrial robot for watchcases, the polishing efficiency should be improved. Based on the quintic B-spline fitting curve trajectory planning method associated with the optimal time interval and the trajectory point angle, the trajectory route of the flexible polishing industrial robot for case parts was optimized by the Matlab software. The operation time of the flexible polishing industrial robot could reach the optimal level. The joints of the robot can be cooperated with each other to ensure that the motion track of the end-effector of the robot arm is closer to the expected motion track. Based on the Adams software, the obtained trajectory curve of multi-objective optimization was simulated, which verified the trajectory fitted after multi-objective optimization. The angular acceleration and angular plus acceleration curves were improved. Theoretical guidance was carried out for the subsequent experiment by Matlab and Adams simulation analysis.

Key words: trajectory optimization; multi-objective optimization; Matlab software; Adams software; industrial robot

Introduction

When industrial robots work, they are generally expected to have shorter working time and more stable operating process to reduce production costs, increase product output, and improve product quality[1]. In this regard, shortening the working time of industrial robots is the goal pursued by enterprises. The movement time of industrial robots reflects the production efficiency of enterprises. A short time reflects the high utilization rate and high work efficiency of industrial robots[2]. A smooth movement of industrial robots can improve the accuracy of robot running trajectory, guarantee the real-time tracking function of robots, and maximize the advantages of robots[3].

When trajectory planning is carried out for industrial robots in the joint space[4], quintic B-spline fitting curves are selected to obtain and optimize the trajectory by the Matlab software. After the trajectory is determined, the optimal time interval needs to be found for the trajectory so that angular velocity curves, angular acceleration and angular plus acceleration kinematics curves of the trajectory could meet various technical indices in robot design[5]. A long-time interval means inefficiency while a too short-time interval will lead to an increase of the movement speed and driving moment of each joint of the industrial robot[6], enhancing the impact vibration of each joint and reducing the service life of the industrial robot.

After the time interval is determined[7], kinematic constraints of each joint of the robot need to be considered. Mathematical ideas can be introduced to transform the optimization problem into a mathematical problem and establish an optimization objective function. The nondominated sorting genetic algorithm (NSGA) is proposed and NSGA-II algorithm that is developed from the NSGA algorithm[8]is adopted as the multi-objective optimization algorithm. This paper establishes a multi-objective optimization model, determines the optimized objective function, and obtains the optimized trajectory route. Based on the Adams software, a three-dimensional (3D) model is established to simulate the trajectory curve of multi-objective optimization and verify the trajectory. Angular acceleration and angular plus acceleration curve fitted after multi-objective optimization.

The polishing wheel used by the polishing machine is made of cotton and linen, which belongs to the category of flexible polishing. This work carries out multi-objective trajectory optimization considering the shortest running time and the minimum running impact as the target. By comparing the simulation analysis of the Matlab software and the Adams software, the theoretical discussion is carried out for the subsequent experiments, which is also instructive for the specific experiments.

1 Polishing Objects of Flexible Polishing Industrial Robots

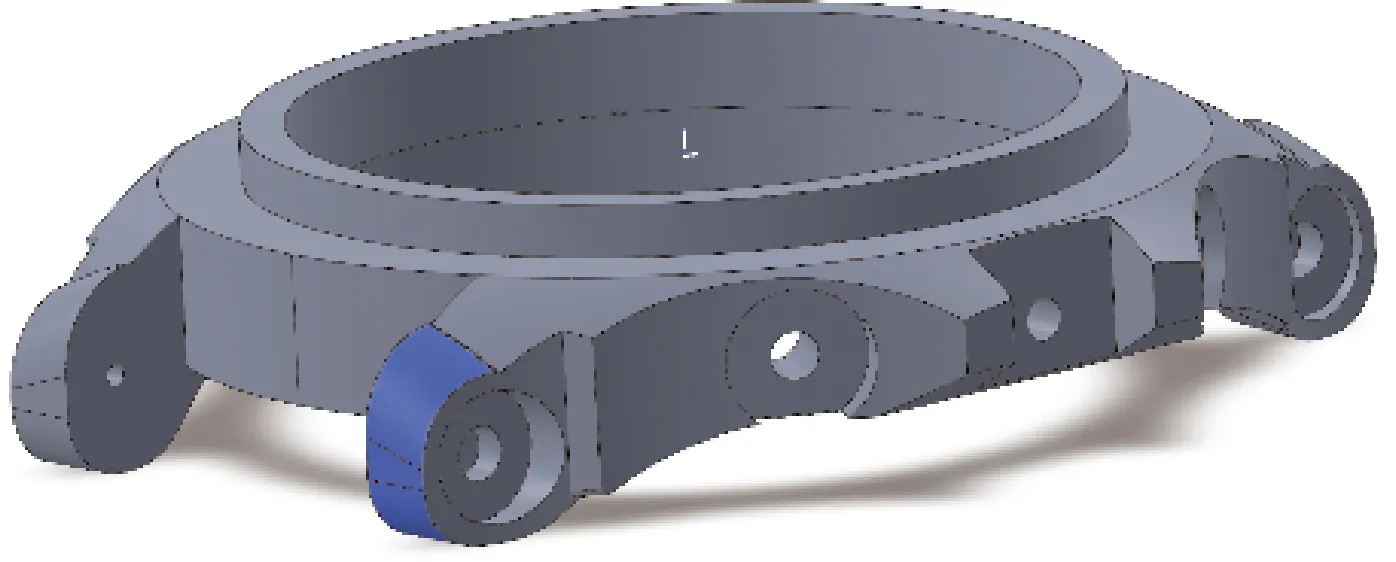

The polishing object of the flexible polishing industrial robot prototype developed in this paper is the outer case of a watch, as shown in Fig. 1. The outer case was produced by a company in Jiangxi Province, China. It is a single round case and its polishing surface belongs to a complex surface. The flexible polishing industrial robot was grasping the case for polishing in Fig. 2.

Fig. 1 Physical appearance of single round case

Fig. 2 Case polishing process

The research object of this paper is the external case of a single circular case. The 3D model is shown in Fig. 3. In this paper, the trajectory optimization is mainly carried out for the polishing track of the complex outer curved surface of the watchcase. The polished surface is the blue part shown in Fig. 4.

Fig. 3 3D model of single round case

Fig. 4 Watchcase table ear part to be polished

2 Establishment of Objective Optimization Model

The trajectory planning of the joint space for polishing industrial robots is based on the given path points and relative response time nodes. When quintic B-spline curve which is derived from the Bezier curve interpolation is applied to generate the trajectory, the constraints of the polishing industrial robot prototype are not introduced.

The B-spline curve is derived from the Bezier curve, which inherits all the advantages of the Bezier curve and complements the local controllability that the Bezier curve lacks at the same time. The B-spline curve which is derived from the Bezier curve improves the replicability of a trajectory planning algorithm and shortens the research and development cycle of the algorithm. In the trajectory planning of robots, the replicability of the B-spline curve improves the adaptability of industrial robots in dynamic environments. Compared with the joint trajectory kinematics curve planned by cubic and quintic polynomial interpolations, the joint trajectory kinematics curve fitted by the quintic B-spline fitting curve runs more smoothly. Therefore, the quintic B-spline curve is selected to study the joint trajectory curve in this paper.

In the practical work of the developed prototype, in order to improve the operation efficiency and stability, the operation trajectory curve with the shortest running time and the minimum joint impact is taken as the key research direction.

2.1 NAGA-II algorithm

Compared with the NSGA algorithm, the NSGA-II algorithm adds the elite strategy mechanism. This algorithm introduces the idea of fast non-dominant sorting, which reduces the complexity of the NSGA algorithm. It has the advantages of fast running speed and good convergence of the solution set, and has become the benchmark for the performance of other multi-objective optimization algorithms.

2.2 Optimization objective function

The objectives of trajectory optimization are the shortest time and the smallest impact in this paper.

2.2.1Constructionoftimeobjectivefunction

Based on the spatial position relationship between the three-jaw chuck clamping method at the end of the robotic arm and the curved surface to be polished, the target trajectory of the gripper at the end of the robotic arm (the center of the case dial) is determined by the shape of the curved surface to be polished.

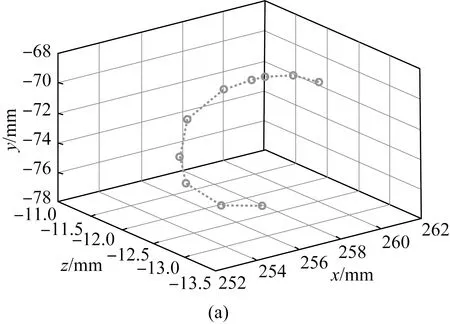

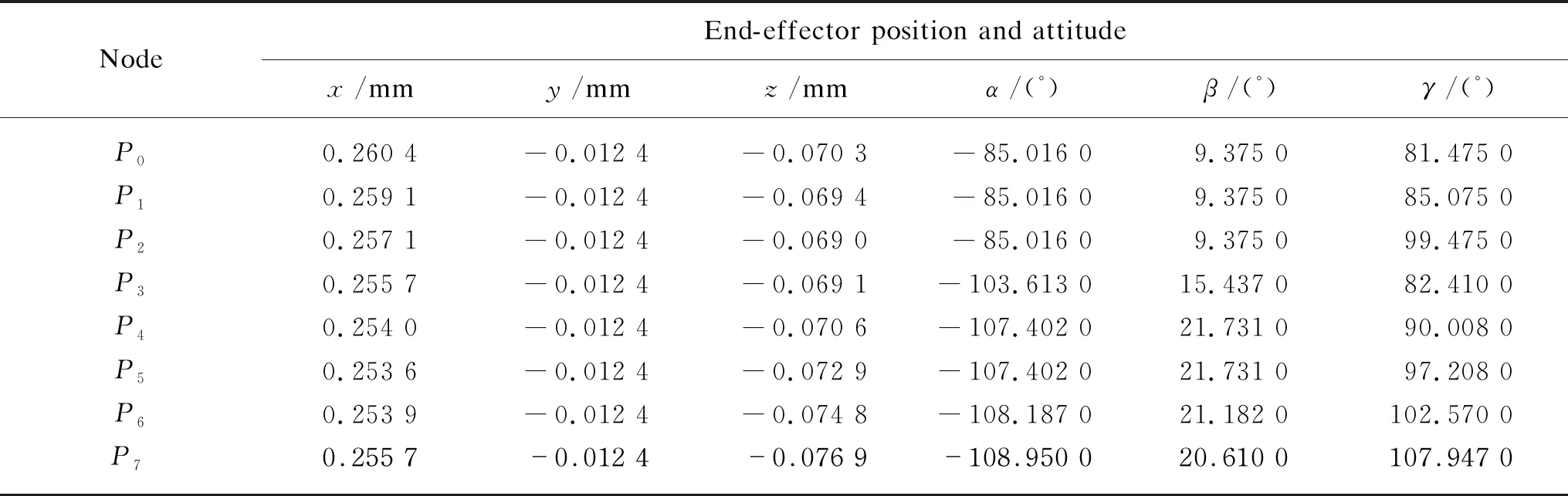

Several key points at the center of the width of the surface to be polished are selected as interpolation points, as shown in Fig. 5. It depicts the image of the value points by the Matlab software. The polishing track of the polishing industrial robot prototype is shown in Table 1.

Fig. 5 Selection of polishing key type value points on curve: (a) 3D; (b) 2D

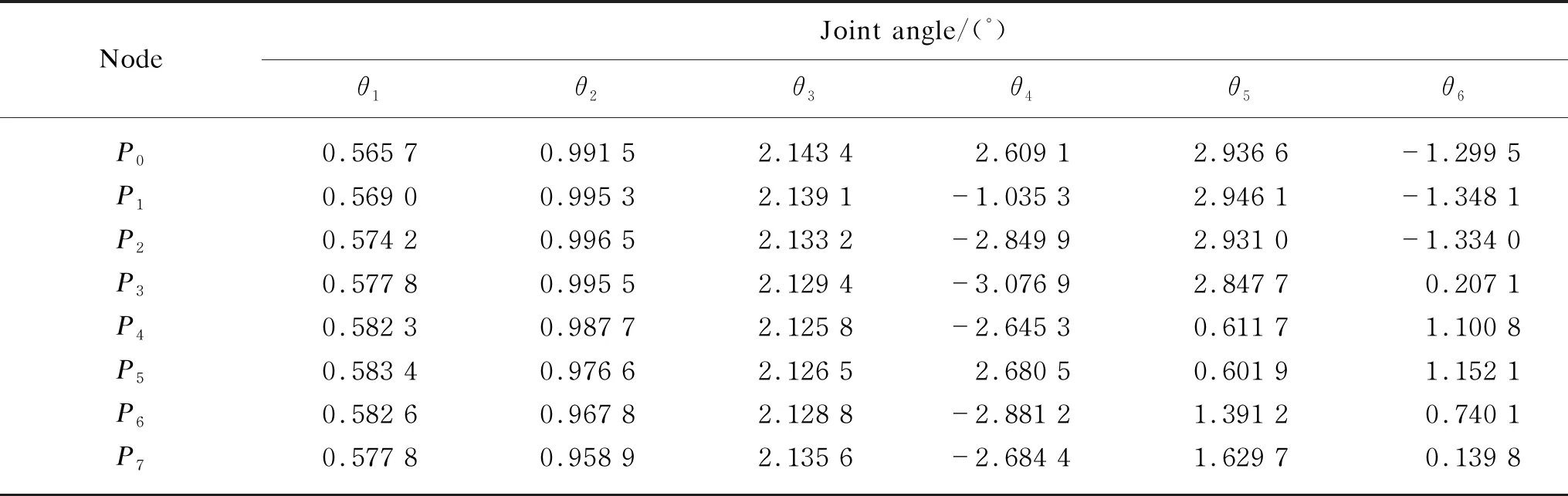

x,yandzrepresent the coordinates of the type value points.α,βandγrepresent the terminal attitudes of the manipulator. There are altogether eight polishing track points, namelyP0,P1, …,P7. The joint node values of six joints can be obtained by solving the inverse kinematics and the angle values of each joint are shown in Table 2.

Table 1 Key type value points data selected on the polishing track

Table 2 Joint angle values of key points in polished trajectories

Suppose that the time interval between two adjacent polishing locus points is Δti(i=1, 2, …, 7).The total running time of the polishing track of the prototype can be obtained by

(1)

2.2.2Impactobjectivefunction

The angular acceleration curve can show the variation rule of angular acceleration of each joint of industrial robots, which is closely related to the force exerted on each joint. The angular acceleration of each joint of the prototype changes too fast, which would make the force on the joint fluctuate greatly. In order to improve the tracking accuracy of the polishing track and reduce the impact of the developed prototype and the wear of each joint, it is particularly important to reasonably plan the polishing track with a small angular acceleration value[11-12].

The trajectory curve of a joint of the robotic arm is expressed by a fifth-order polynomial curve expression. The number of boundary conditions is six, and the beginning conditions are the angle constraint points, the angular velocity constraint, and the angular acceleration constraint.

Generally, the angular velocity of starting and ending points are assumed to be zero for the convenience of calculation. Then the angle and the angular velocity of the two points are

(2)

wheret0is the starting time andtfis the ending time. Similarly, the angular acceleration at starting and ending points are assumed to be zero:

(3)

The fifth-order polynomial curve expression is set to

θ(t)=a0+a1t+a2t2+a3t3+a4t4+a5t5,

(4)

wherea0,a1,a2,a3,a4anda5are coefficients. The first derivative and the second derivative of Eq.(4) are

(5)

Substitute Eq.(2)and Eq.(3)into Eq.(5):

(6)

Sort Eq.(6):

(7)

Substitute the angular velocity and angular acceleration constraint conditions of starting and ending points into the Eq.(7):

(8)

So the joint angle, angular velocity, angular acceleration trajectory functions are

(9)

For thejth joint, the impact magnitude is expressed by the integral of the absolute value of the third derivative of the angle curve to the polishing running time.

(10)

whereJjmeans the impact of joint andjmeans the number of joints.

2.2.3Globalobjectivefunction

There are two optimization objectives in this paper: the shortest time and the smallest impact. When dealing with the multi-objective function, the weighted sum of two objective functions is taken as the overall objective function:

F(x)=λ1Ft(x)+λ2Fj(x),

(11)

whereF(x) represents the overall objective function,Ft(x) represents the time objective function, andFj(x) represents the impact objective function.λ1andλ2are the weights of the two sub-objective functions. The object studied in this paper has a high requirement on polishing quality. It is determined asλ1=0.4 andλ2=0.6.

2.3 Constraint function

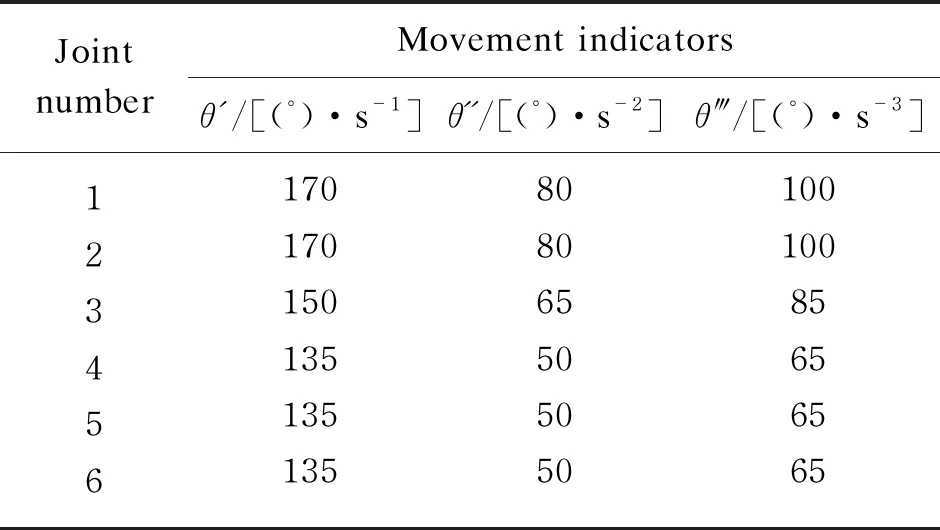

In practice, in addition to the constraints of physical positions and driving physical performance, the bearing capacity of each joint of polishing industrial robots should be fully considered, otherwise robots would be damaged irreversibly. The speed and the acceleration of all joints of the polishing industrial robot studied in this paper as well as the constraints of acceleration are determined by the performance parameters of the driving device itself. The constraints are shown in Table 3.

Table 3 Robotic joint motion constraints

The constraints of the jointjin the motion process of the polishing industrial robot prototype are mainly as

(12)

According to the quintic B-spline curve fitting method, the trajectory of each joint of the developed prototypeθj(t) is a function of timet.Based on analytical expressions of the angle value function, the angular velocity value function and angular acceleration value function of each joint of the polishing industrial robot, the maximum value should be less than the constraint value to find the absolute value of each function. For any jointj,

(13)

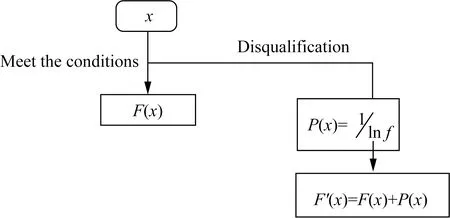

Among them, Eq. (3) is a nonlinear constraint. In the optimization process, the nonlinear constraint conditions usually need to be considered. In this paper, the penalty function method is used to deal with the nonlinear constraint conditions.

The principle of the penalty function method is to add a penalty operator function. It reduces the fitness of the members of the parent generation and the members would be eliminated in the sorting. Specific working steps are shown in Fig. 6, whereF(x) is a fitness function andP(x) is the penalty operator function.

Fig. 6 Principle of the penalty function method

(14)

Through the processing of Eq. (6), the fitness function value of parent individuals who do not meet the constraints is infinitively small. Those parent individuals are sorted to the end of the sequence, thus being eliminated. This method can shorten the operation time of the algorithm.

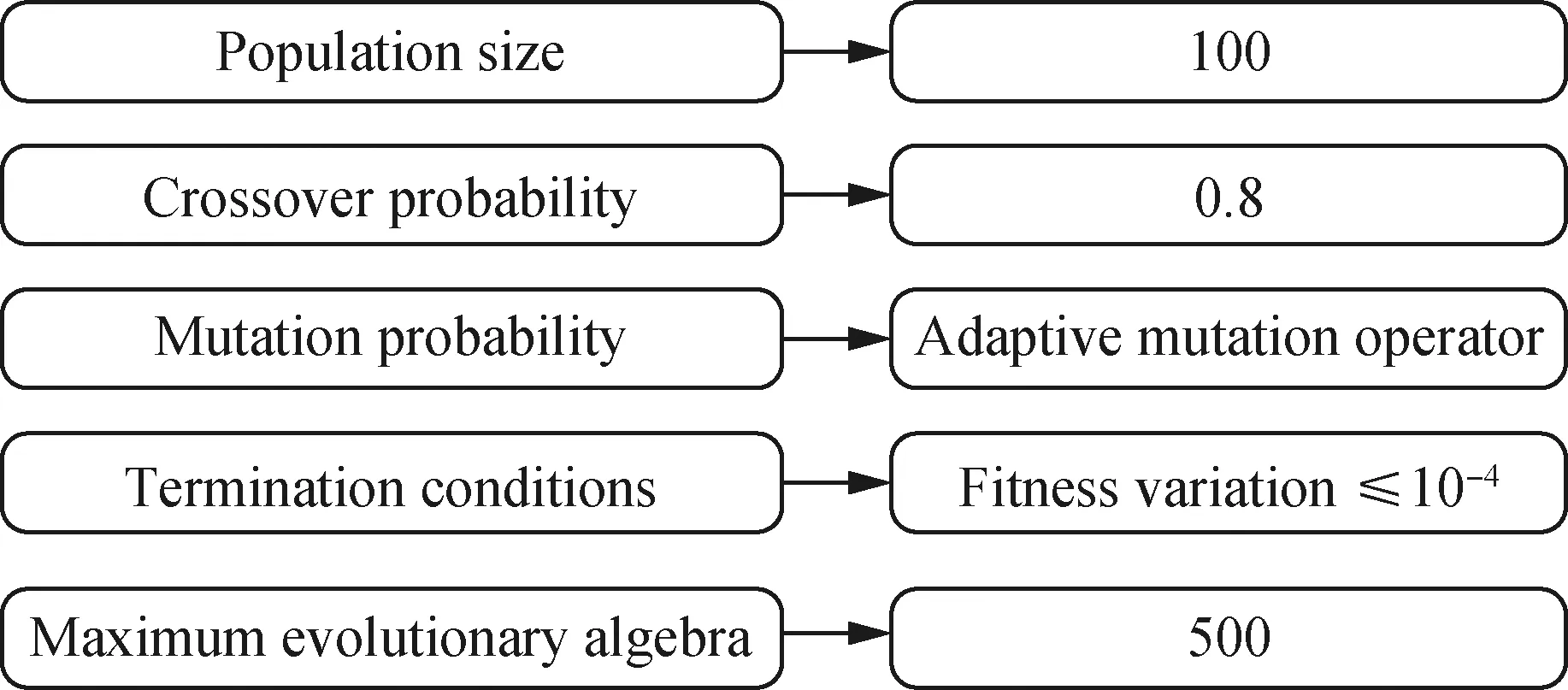

2.4 Setting of the NSGA-II algorithm parameters

The set values of parameters required by the NSGA-II algorithm are shown in Fig. 7.

In Fig. 7, the working principle of the adaptive mutation operator is to match the corresponding mutation probability for individuals with different fitness values. In the calculation of the algorithm in this paper, the individual with a small fitness value matches a large probability of variation, while the individual with a large fitness value matches a small probability of variation.

Fig. 7 Schematic diagram of NSGA-II algorithm parameter setting

2.5 Optimization results and analyses

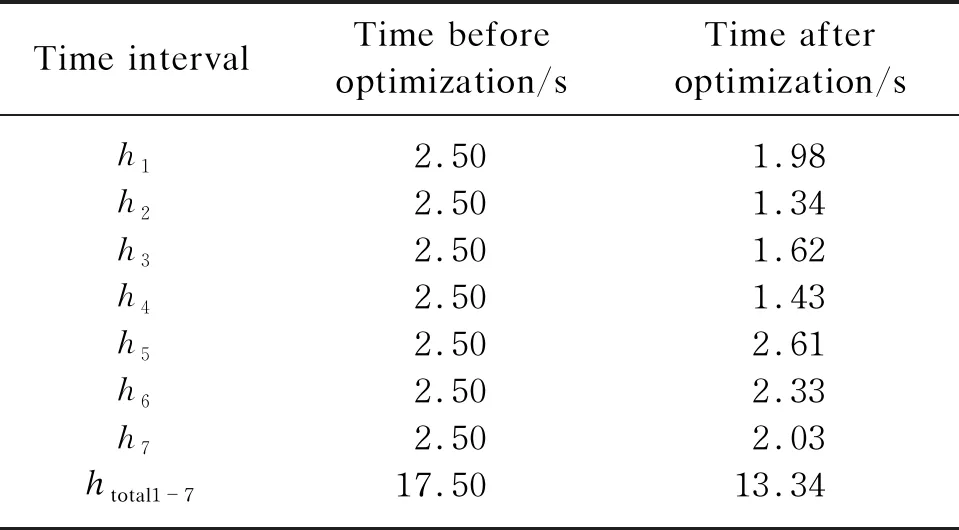

After setting the parameters of the NSGA-II algorithm, the polishing trajectory of industrial robots is optimized for multiple targets. Two objective functions,i.e., time and impact, are set. The comparison between the time series before and after the NSGA-II algorithm optimization is shown in Table 4.

Table 4 Comparison of time series before and after the NSGA-II algorithm optimization

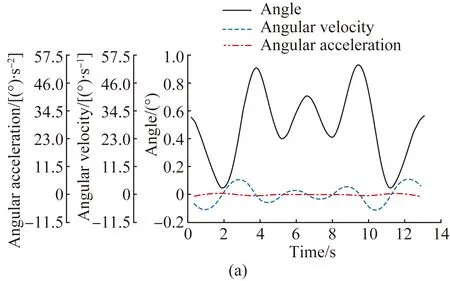

After multi-objective optimization, the kinematic trajectory curves of the six joints after quintic B-spline curve fitting are shown in Fig. 8, which is simulated by the Matlab software.

Fig. 8 Quintic B-spline kinematics trajectory curve of six joints after multi-objective optimization:(a) joint 1; (b) joint 2; (c) joint 3; (d) joint 4; (e) joint 5; (f) joint 6

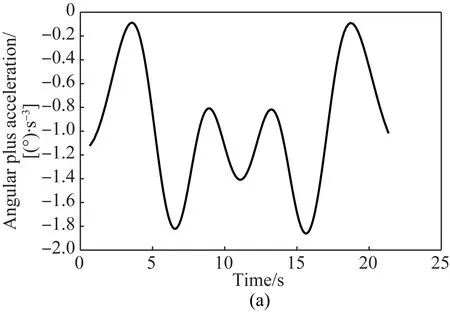

As can be seen from Fig. 8, it shows the trajectory curves of angle, angular velocity and angular acceleration of the six joints at the same time by the Matlab software. After the NSGA-II algorithm optimizes the polishing track, the time is reduced by 4.16 s, which proves the feasibility of the algorithm. The angular plus acceleration curves of the six joints before and after optimization are shown in Fig. 9 and Fig. 10, respectively.

Fig. 9 Trajectory curve fitted by quintic B-spline curve: (a) joint 1; (b) joint 2;(c) joint 3; (d) joint 4; (e) joint 5; (f) joint 6

Fig. 10 Kinematic curve of six joints after multi-objective trajectory optimization: (a) joint 1; (b) joint 2;(c) joint 3; (d) joint 4; (e) joint 5; (f) joint 6

As can be seen from Fig. 9 and Fig. 10, the angular plus acceleration trajectory curves obtained by the quintic B-spline fitting method after multi-objective optimization are more stable by the Matlab software. The impact force is greatly reduced, which proves the effectiveness of the NSGA-II algorithm.

Based on the working principle of the NSGA-II algorithm, the time optimization objective function and the energy optimization objective function of polishing industrial robots are established with time optimization and impact minimization as the optimization objectives. By constructing the total objective function with weighted summation, the constraint conditions of the complex curved surface of the flexible polishing industrial robot prototype are introduced and the kinematic constraint conditions of the robot joints are dealt with by the penalty function method. According to the specific polishing track, the Matlab software is used to solve the optimal time interval. The results show that the impact track curve of each joint has been significantly improved compared with that before the optimization.

3 Motion Simulation of Flexible Polishing Industrial Robot Prototype

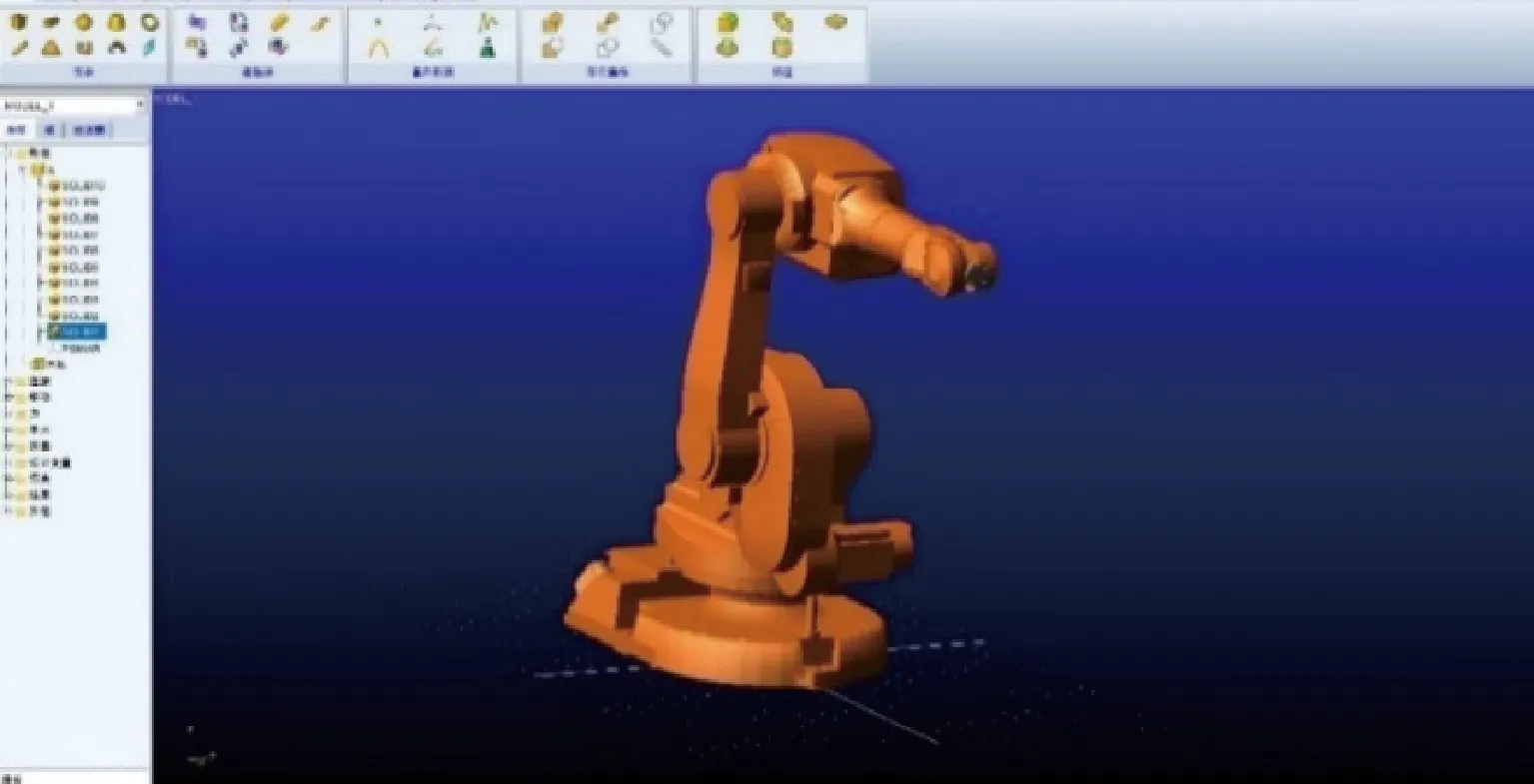

By comparing the quintic B-spline trajectory curve after and before multi-objective optimization, it is verified that the fitted trajectory after multi-objective optimization, the curve of angular acceleration, and angular plus acceleration are improved. The polishing industrial robot prototype developed in this paper has a complex mechanical structure consisting of many parts. Given the weak ability of the Adams software creating 3D models[13-14], the SolidWorks software is used to build 3D models of the developed prototype. It is imported into the Adams software for further simulation research.

3.1 Establishment of Adams simulation model

In the Adams software, importing 3D models requires the same file extension format, which is built by SolidWorks software. After importing the polishing industrial robot prototype into Adams software, the imported prototype model would be displayed as shown in Fig. 11.

Fig. 11 Model of polishing industrial robot prototype in Adams

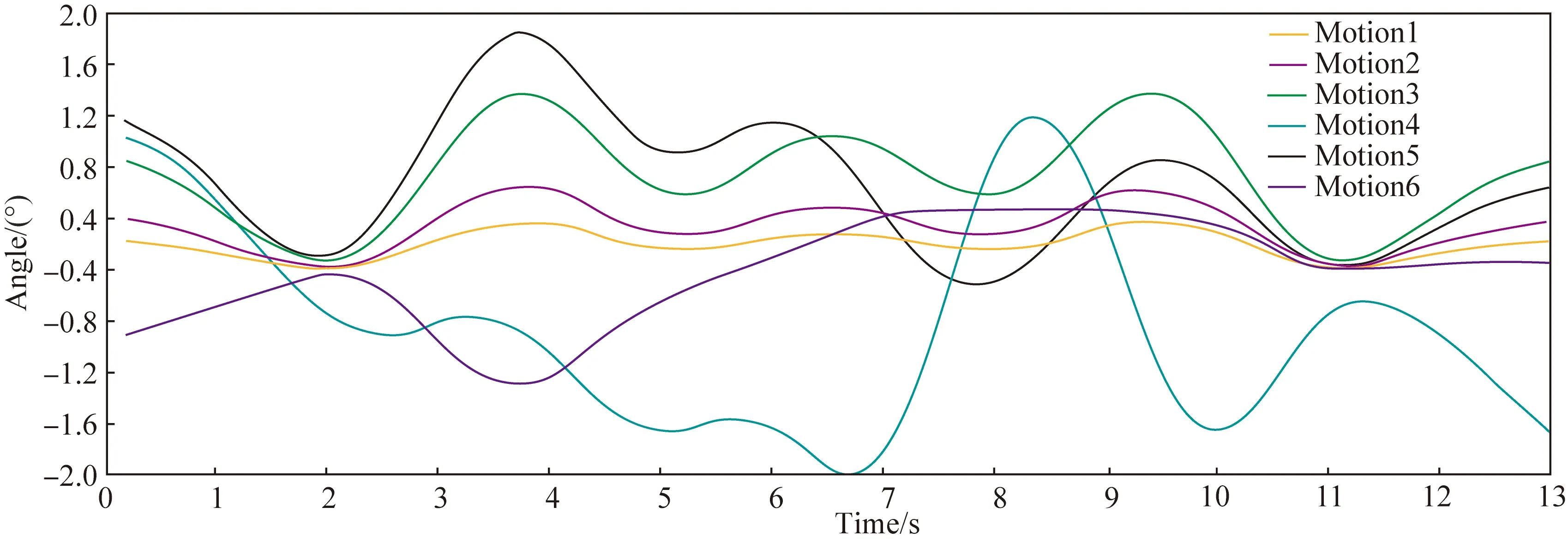

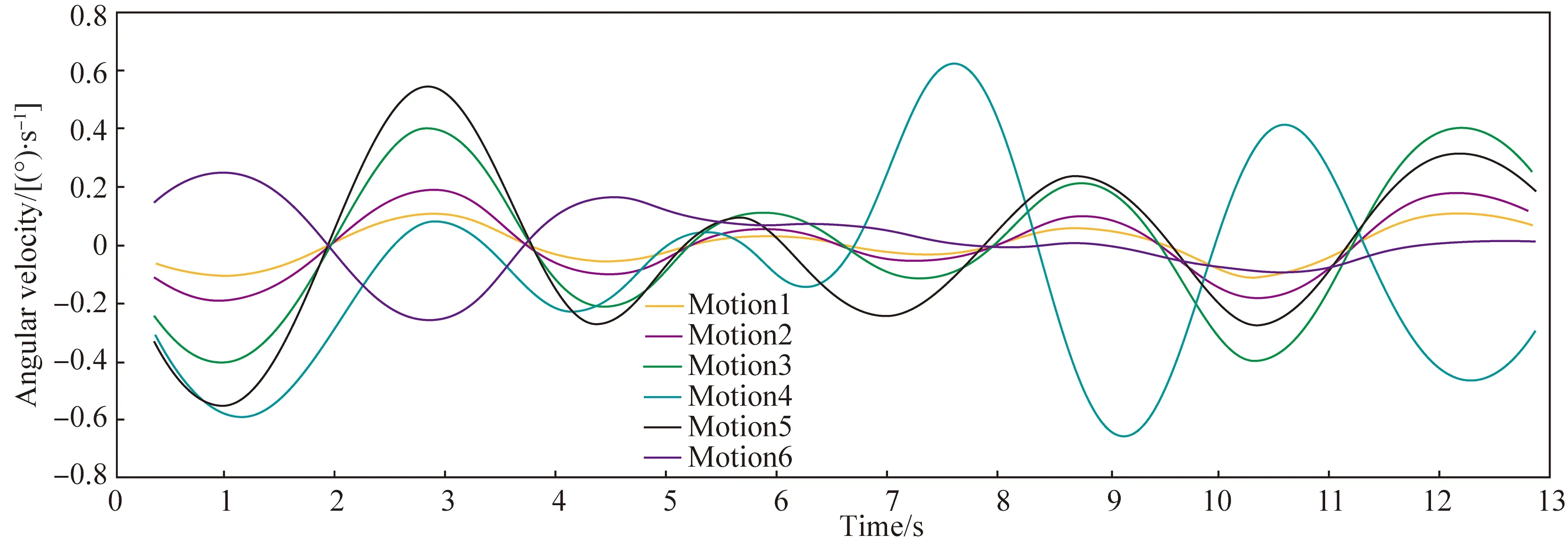

Fig. 12 Angle constraint curve of each joint after multi-objective optimization

Fig. 13 Angular velocity constraint curve of each joint after multi-objective optimization

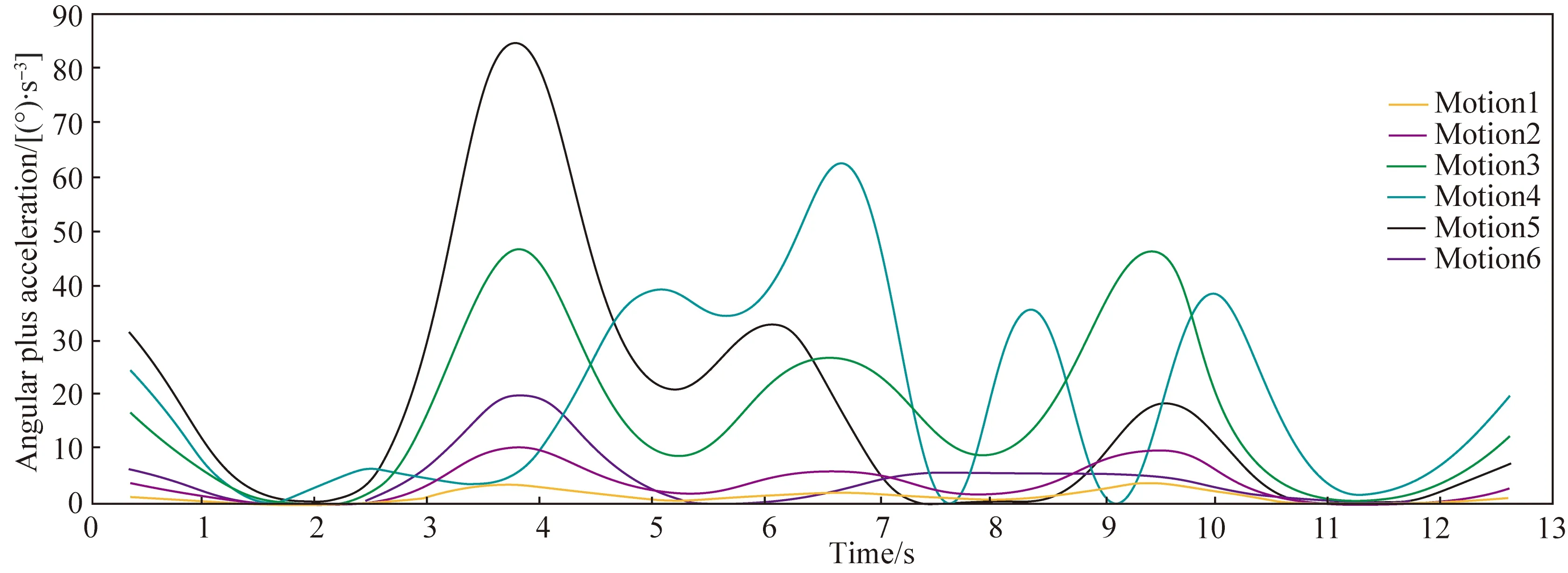

Fig. 14 Angular acceleration constraint curve of each joint after multi-objective optimization

3.2 Simulation verification of optimized trajectory

To begin with, a connection relationship is established for the polishing industrial robot prototype model. The six joints of the research object in this paper are all rotary joints. Then the driver is built. The six joint axes in the developed prototype model are then selected. Rotation drivers are defined for six joint axes in turn. Each driver established is found in the model tree and the multi-objective optimized spline curve is input into the joint drive.

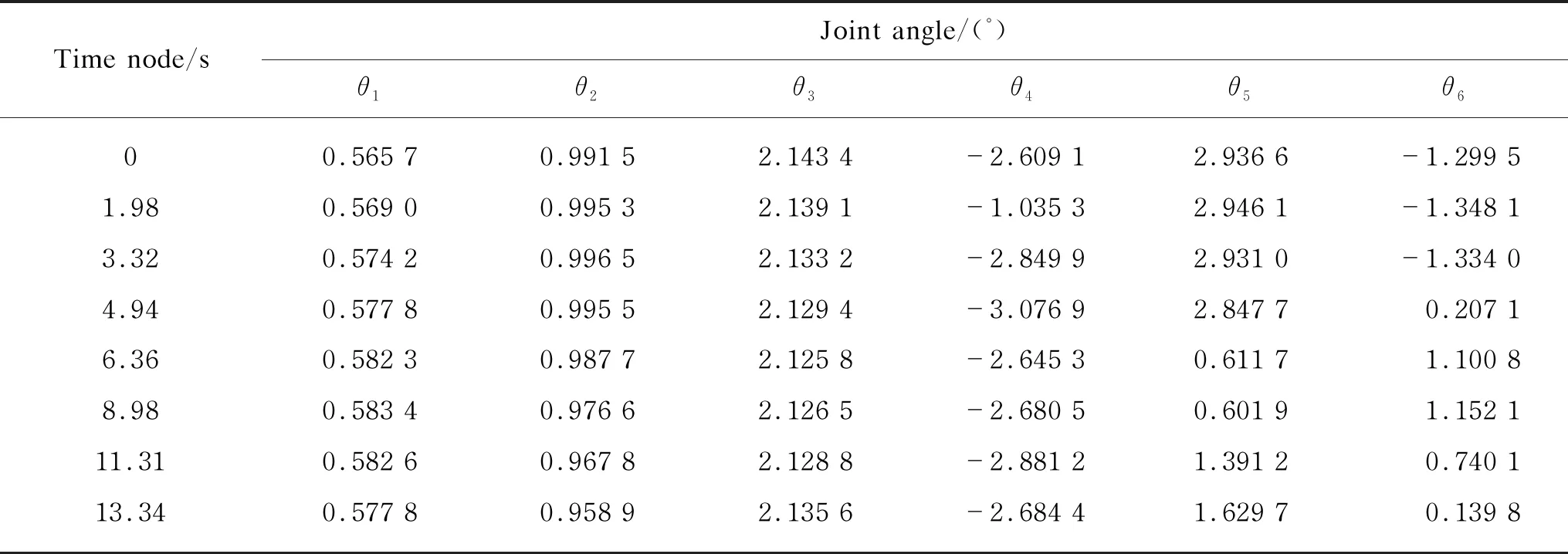

The optimal time interval result obtained by the optimization of the NSGA-II algorithm is shown in Table 3. According to the time interval, the time series of the polishing trajectory points of each joint is shown in Table 5.

Table 5 NSGA-II multi-objective optimized polishing trajectory point time series

Set the simulation time as 13.34 s and set the number of steps as 500 during the Adams kinematic simulation. Taking the origin of the base directly below joint 1z-axis as a reference point, thez-axis direction is set. The kinematic change curves of angle, angular velocity, and angular acceleration of the six joints of the developed prototype are obtained. Taking the derivative of the diagonal acceleration curve, the angular plus acceleration curve for the six joints are attained.

3.3 Multi-objective optimization of polishing trajectory analysis verification

3.3.1Prototypeconstraintverification

The constraints of the prototype are motion angle, angular velocity, and angular acceleration of the joint. The kinematic curves of each joint after multi-objective optimization are post-processed by the Adams software, as shown in Figs. 12-14, respectively. The Matlab software and the Adams simulation analysis adopt the same kinematic parameters of joints. By comparing the technical indices of the prototype developed in Table 1, it can be seen that after the NSGA-II algorithm performs multi-objective optimization on specific polishing trajectory, the kinematic trajectory curves of each joint obtained meet the constraint line set in the optimization, which can prove the effectiveness and the feasibility of the penalty function selected in this paper. Moreover, the trajectory of joint operation by the Adams software is also consistent with the trajectory simulated by the Matlab software. The angular velocity curve is smooth and the change of angular acceleration is stable. Motion means trajectories of the six joints.

3.3.2Verificationofoptimizationobjectiveswiththeshortesttimeandminimumimpact

As can be seen from Table 4, the running time of the trajectory planned by multi-target optimization by the Adams software is 13.34 s, which is 4.16 s shorter than that before optimization, proving the effectiveness of this algorithm for the time-optimal target. By taking the absolute value of the angular acceleration curve of each joint of the developed prototype measured in the Adams software and derivative, the impact curve of the developed prototype is obtained as shown in Fig. 15. The impact curve of each joint by the Adams simulation has also been reduced. By comparing with the simulation results by the Matlab software, it illustrates the impact curve of each joint after multi-objective optimization in Fig. 15, which is more comprehensive than single joint impact curve by the Matlab software.

Fig. 15 Impact curve of each joint after multi-objective optimization

Based on the verification of the above two optimization objectives, the Adams simulation analysis has important guiding significance for the theoretical support of the subsequent experiments.

4 Conclusions

In this paper, the NSGA-II algorithm is used to optimize the multi-target trajectory, which can realize the multi-target optimization of the polishing trajectory of the developed prototype under the condition of satisfying the constraints of the polishing industrial robot prototype. It can also greatly improve the precision polishing quality of the prototype, maximize the advantages of the robot, and be applied to the polishing industrial robot’s trajectory planning for complex surfaces.

The constraints of the industrial robot prototype with complex surface flexible polishing are introduced and the kinematic constraints of robot joints are dealt with by the penalty function method. According to the specific polishing track, the Matlab software is used to solve the optimal time interval. The results show that the impact track curve of each joint has been significantly improved compared with that before the optimization, which improves the precision polishing quality of the prototype.

By establishing a 3D model of the polishing industrial robot prototype, the trajectory obtained after multi-objective optimization and the quintic B-spline fitting is simulated and verified by the Adams software, which proves that the optimized trajectory meets the constraint conditions of joint and the optimization effect of multi-objective is good. In summary, the above two kinds of simulation analysis provide important guidance for the subsequent experiments.

猜你喜欢

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Electrochemical Performance of Core-Sheath Dip-Coated Lignin Derived Carbon/Wet-Spun Graphene Electrodes for Fiber-Shaped Supercapacitors

- Preparation and Properties of Polyurethane/Nickel Nanofiber with Core-Shell Structure Using Coaxial Electrospinning Method

- Effect of Supported Bearing Clearance on Load-Sharing Characteristics of a Double-Row Planetary Gear System

- Meta-Analysis on the associations between Prenatal Perfluoroalkyl Substances Exposure and Adverse Birth Outcomes

- Numerical Simulation of Space Fractional Order Schnakenberg Model

- Symmetry Classification of Partial Differential Equations Based on Wu’s Method