可控液体输运制备取向聚合物薄膜:面向性能增强的发光二极管

2021-04-17孟利利陈琳琳张小亮解令海

孟利利,陈琳琳,张小亮,解令海,刘 欢

(1.北京航空航天大学化学学院,仿生智能界面科学与技术教育部重点实验室,北京100191;2.南京邮电大学先进材料研究所,南京210023)

1 Introduction

It is of great significance to prepare oriented organic thin films for efficient charge transfer. Conjugated polymers have been widely used in various optoelectronic devices including thin-film field effect transistors(FETs),light-emitting diodes(LEDs),and photovoltaic cells(PVCs)[1—6]. As the active layer,the polymers film plays an important role in determining the performance of optoelectronic devices. Generally,a polymer film with orientation structure is always preferred for efficient charge transfer across the film[7—9]. Thus,developing a simple and efficient method to fabricate the oriented polymer thin film is in demand.

To date,two categories of strategies have been reported aiming at improving charge carrier mobility and in turn device performance by controlling alignment and morphology of the polymer thin-films.(i)Adjusting intra- and inter-molecular interactions in combination with molecular design principle[10—12].(ii)Various processing techniques where the polymers were aligned under the external forces,including solvent vapor annealing[13],interface modification[14],thermal annealing[15],dip coating[16],spin-coating[17],bar coating[18],slot die coating[19],directional drying[20],and solution-shearing[21,22]. However,these approaches still suffer from the limitations of uncontrollable liquid transfer and low film quality. In general,the essence of fabricating a high quality polymer film is to coat polymer solution onto a substrate that is confined within certain micro-scale area. Therefore,trying to control the wetting and dewetting of the polymer solution on the substrate is rather important. Recently,conjugated polymers were aligned with microstructures either on the substrate or the coating tools by micromachining technology,based on which the way of dewetting can be modified by the microstructures[23,24]. Nevertheless,it involves the complicated fabrication of the microstructures,making the approach difficult in large scale and high cost. Very recently,we demonstrated that the conical fibers array(CFA)enables fine controlling the receding of the tri-phase contact line during the film formation process,by which highly oriented polymer thin films and Ag nanowires film were successfully prepared[25—27]. It suggests that the CFA enables directional wetting and dewetting.

Herein,we proposed a facile CFA-guided liquid transfer approach to oriented bulky polydiarylfluorene(PODPF),followed by a thermal annealing process atca.240 ℃. During this approach,PODPF changed from the amorphous-phase to compactπ-πstackingβ-phase,leading to a PODPF film with higher orientations and larger crystallized sizes. The CFA plays an important role in finely controlling the wetting and dewetting processes under directional stress,which guide the disorganized polymer transform into orientation. Based on the as-prepared PODPF films,a polymer light-emitting diode(PLEDs)device was developed,which exhibited higher current efficiency of 1.53 cd/A(5.6 V)and more stable electroluminescence compared with that of the spin-coating one. We envision that the as-developed approach provides a new applicable and efficient approach in facile fabricating high-performance PLED devices.

2 Experimental

2.1 Materials

Poly[4-(octyloxy)-9,9-diphenylfluoren-2,7-diyl]-co-[5-(octyloxy)-9,9-diphenylfluoren-2,7-diyl](PODPF,Mw=67566)were purchased from Beijing Yili Fine Chemicals Co.,Ltd. Poly(3,4-ethylenedioxythiophene)-doped poly(styrene sulfonic acid)-doped poly-(styrene sulfonic acid)(PEDOT∶PSS,Mw=354.441)was purchased from Heraeus Clevios P VP Al 4083. Chlorobenzene(CB,C6H5Cl,Mw=112.56)was purchased from Beijing lanyi Chemical Products Co.,Ltd.

2.2 Preparation of the Polymer Film

The PODPF was dissolved in chlorobenzene with a total concentration of 10 mg/mL for CFA-coating(8 mg/mL for spin-coating). For the CFA-brushing process,the polymer solution was transferred onto the substrate guided by the CFA in a well-controllable manner. The brushing speed was controlled by a stepper motor,which allows the CFA to fine-tune the wetting/dewetting process at an appropriate brushing speed.Spin-coated films were fabricated at 2500 r/min for 30 s. Then,the as-prepared films at various speed were annealed at 240°C.

2.3 Film Analysis

The optical properties were measured using an ultraviolet-visible spectrophotometer(UV-2600,SHIMADZU)in the wavelength range of 300—600 nm. The surface morphology of the PODPF films was observed on an atomic force microscope in ScanAsyst under ambient conditions(FASTSCANBIO,Bruker,Germany).Film thickness was tested on a Profilometer(Dektak XT). The polymer films were characterized by means of polarized UV-Vis absorption spectroscopy. The current-voltage luminescence characteristics of the devices were measured with a Keithley source meter(model 2602)coupled with a luminance meter.

2.4 Fabrication of PLED Device

The PEDOT∶PSS solution was spin-coated onto an indium-tin oxide(ITO)glass. Then,the PODPF films were CFA-brushed on the top of the PEDOT∶PSS layer. Next,a TPBi layer was prepared by thermal evaporation in vacuum. Finally,using a shadow mask,LiF(0.8 nm)and Al(100 nm)electrodes were deposited under a high vacuum.

3 Results and Discussion

3.1 CFA-brushing Process

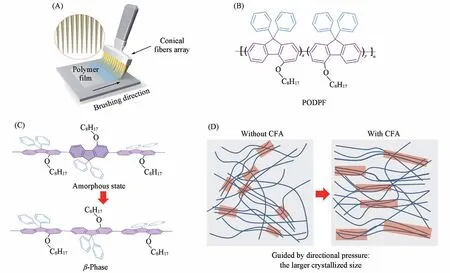

Fig.1 Schematic illustrations of CFA⁃brushing process(A) and the chemical structure of the polymer PODPF(B), schematic illustration of transformation from the amorphous state to the β⁃phase(C)and PODPF film with higher orientations and larger crystallized sizes induced by the CFA(D)

Using the CFA,the polymer solution was steadily transferred onto substrate in a well-controlled manner,as schematics illustrated in Fig.1(A). As shown in Fig.1(B),the polymer of PODPF was particularly used due to its good air-stability and high crystalline nature. As has been reported,the CFA is capable of steady holding the polymer solution under the cooperative effect of the Laplace pressure difference(FL),asymmetrical retention force(Fa),and gravity(G),without any leakage. It is proposed that the CFA enables shaping the tri-phase contact line into multiple small meniscus curves,leading to parallel directional stresses to align the conjugated backbones at certain orientation[25—27]. By such CFA-brushing process,the disorganized polymer transformed into orientation under directional stresses,where the receding of the tri-phase contact line was finely controlled during the wetting/dewetting process. As a result,the PODPF film of amorphous-phase was prepared on substrate. Then,the as-prepared PODPF film was thermal-annealed atca.240°C,by which the transition of PODPF film from amorphous-phase to compactπ-πstackingβ-phase was realized,as has been reported[Fig.1(C)][28,29]. Ultimately,a PODPF film with higher orientations and larger crystallized sizes was prepared[Fig.1(D)].

3.2 Optical Properties of the As-prepared PODPF Film

Fig.2 Optical pictures of the as⁃brushed PODPF film based on amorphous and β⁃phase PODPF at various brushing speed, and that prepared by spin⁃coating(A), UV⁃Vis spectra of PODPF films with amor⁃phous and β⁃phase PODPF(B) and the polarized UV⁃Vis absorption spectra of CFA⁃brushed and spin⁃coated PODPF films(C)

During our experiments,we found that the brushing speed plays a critical role in achieving high orientation. To assess the influence of brushing speed on the alignment of PODPF film,we prepared a series of PODPF film at various brushing speed. Optical pictures under the illumination of a 365 nm wavelength UV lamp[Fig.2(A)]shows that the brightness of both the amorphous-phase andβ-conformation films have a variation with increasing the brushing speed. Meanwhile,it clearly suggests that the amorphous conformation film emits blue light and theβ-conformation film emits yellow green light. The PODPF film prepared by CFA-brushing method is more uniform than that prepared by spin coating method. As shown in Fig.2(B),the absorption spectrum of the spin-coated PODPF amorphous-phase film from chlorobenzene solution shows a maximum at 385 nm,suggesting the amorphous state. However,dramatic differences appeared after thermal annealing. Theβ-conformation of PODPF is planar with an extended effective conjugation length,which can be probed by the characteristic shoulder in the normalized absorption spectrum at 437 nm in addition to the main peak at 413 nm[Fig.2(B)]. The spectra of CFA-brushed PODPF films are shown in Fig.S1(see the Electronic Supplementary Material of this paper),showing that the peak position of both the amorphous-phase andβ-conformation films remain unchanged while the strength of spectrum is lower than that of the spin coated films. This is due to the lower film thickness of CFA-brushed PODPF films. For the CFA-brushed films,the UV-Vis absorbance of theβ-phase films is higher than that of the amorphous films,indicating that the light transmittance of the polymer film decreases after thermal annealing. The variation magnitude of absorbance spectra of the PODPF films prepared at various speed is different,which is attributable to the change of polymer crystal thickness. To demonstrate the anisotropy of the as-prepared PODPF film,the polarized UV-Vis absorption spectra were conducted,and the difference between parallel and orthogonal polarized-light absorbance(ΔA,Aparallel-Aperpendicular)along the brushing direction were summarized[Fig.2(C)]. It clearly suggested that the CFA-brushed polymer film showed pronounced polarized UV-Vis absorption,and the absorption reached a maximal value of 2.3×10-3at brushing speed of 800 μm/s. The results directly evidenced the high alignment of polymer chains in the film. For comparison,little polarity was detected for the spin-coated film. It is suggested that the CFA enables the aligning of conjugated backbones,as we recently reported[25—27].

It is proposed that brushing speed makes an immediate impact on the area of transition region with controlling the duration time for self-assembly of polymer chains under directional stress. When the brushing speed is low,the duration time for aligning polymer chains is very short. When the brushing speed is high,duration time is long enough for the aligned polymer chains to be disassembled. Therefore,suitable brushing speed plays an important role in controlling the dewetting process under certain direction,which makes the crystallization proceed and self-assembly of conjugated backbones by fibers at good timing. Consequently,the highly oriented polymer films are realized.

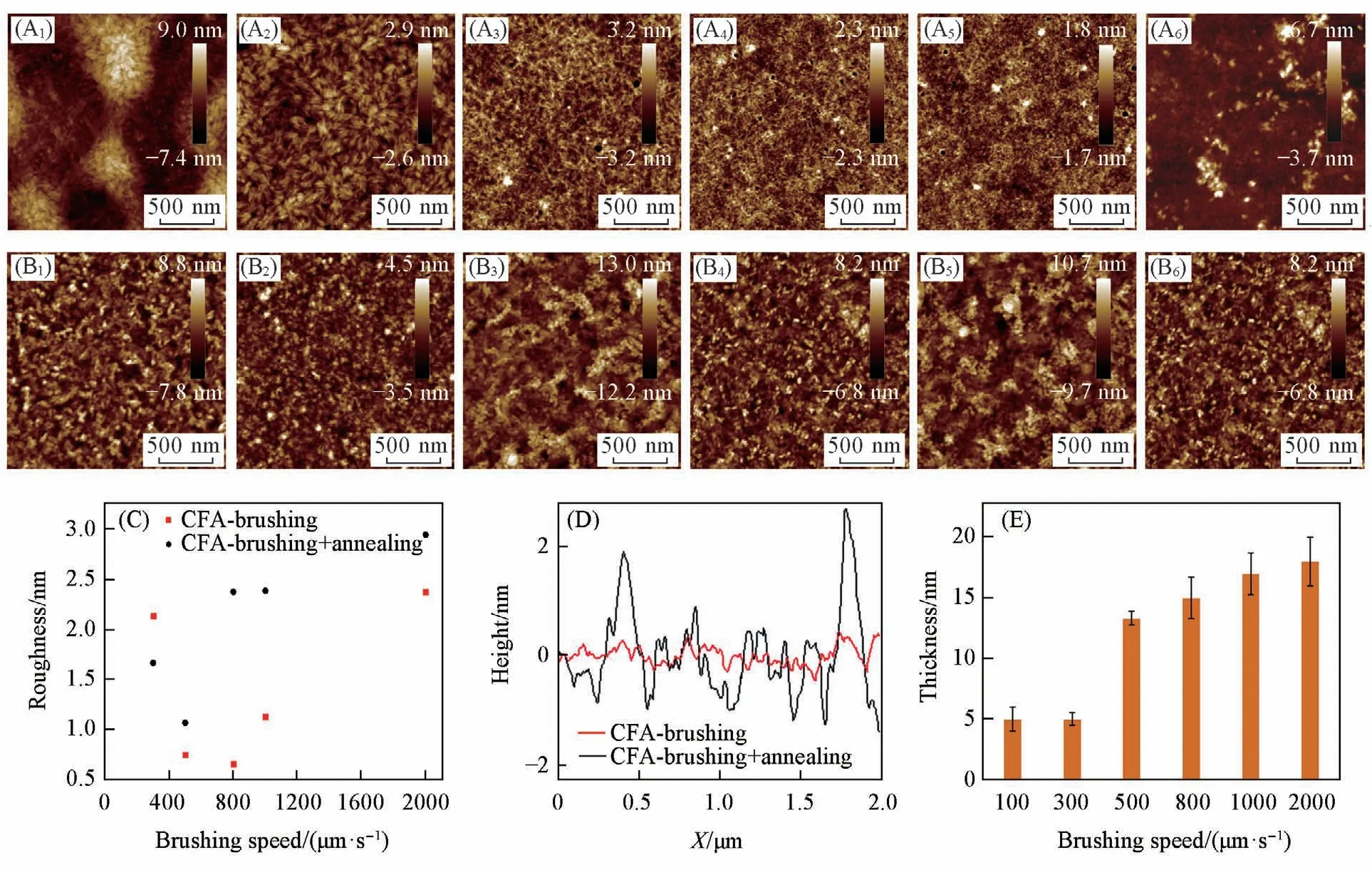

3.3 Morphology of the As-prepared PODPF Film

The as-prepared PODPF films were characterized by atomic force microscopy(AFM). Fig.3(A)and(B)show the surface morphologies of the PODPF films based on amorphous-phase andβ-conformation of PODPF at various brushing speed. As shown,the PODPFβ-conformation films clearly show the change of polymer crystal thickness,appearing larger granular structures in the film compared with the PODPF amorphous-phase films. With increasing the brushing speed from 300 μm/s to 500,800,1000 and 2000 μm/s,the PODPF amorphous-phase films show a root-mean-square(RMS)roughness of 2.14,0.75,0.66,1.13 and 2.38 nm,respectively[Fig.3(A1—A5)],and the PODPFβ-conformation films show a RMS roughness of 1.67,1.07,1.45,2.39 and 2.95 nm,respectively[Fig.3(B1—B5)]. The roughness of CFA-brushed PODPF films based on the amorphous-phase andβ-conformation of PODPF gradually decreases and then increases with the increasing of the brushing speed. For comparison,the spin-coated amorphous-phase[Fig.3(A6)]andβ-conformation[Fig.3(B6)]films show less granular structures in the film but give a higher RMS roughness of 1.75 nm(amorphous-phase),2.11 nm(β-conformation),respectively[Fig.3(C)]. The results suggest that the appropriate brushing speed lead to pronounced aggregation domains. Notably,the PODPFβ-conformation film at the brushing speed of 800 μm/s shows clear larger crystallized sizes but with smaller roughness(RMS:1.45 nm),which is preferred for efficient charge transfer. The roughness curve of both the amorphous-phase andβ-conformation films prepared at the brushing speed of 800 μm/s are shown in Fig.3(D),suggesting that the annealed film clearly shows the change of polymer crystal thickness. The thickness of the PODPF film can be tuned by changing the brushing speed. The film thickness wasca. 5 nm at brushing speed of 300 μm/s and gradually increased to(17±2.3)nm with enlarging the brushing speed to 2000 μm/s[Fig.3(E)]. Taken together,the appropriate brushing speed facilitates the formation of pronounced aggregation domains,which is beneficial for the charge transport.

Fig.3 AFM images of the CFA⁃brushed PODPF films based on amorphous(A1—A5)and β⁃phase(B1—B5)PODPF at different brushing speed,AFM images of the spin⁃coated PODPF films based on amor⁃phous(A6)and β⁃phase(B6)of PODPF,the film roughness of the CFA⁃brushed PODPF films at dif⁃ferent brushing speed(C), representative AFM height image of the CFA⁃brushed PODPF films at the brushing speed of 800 μm/s(D)and effect of brushing speed on the film thickness(E)

3.4 Performance of the As-prepared PLED

Taking advantage of the high-quality polymer film prepared by CFA-brushing,PLED devices with an architecture of ITO/PEDOT∶PSS/PODPF/TPBi/LiF/Al were fabricated[Fig.4(A)]. Here,to meet with both higher orientations and larger crystallized sizes,the brushing speed of 800 μm/s was used,which enables better aligning conjugated backbones. As shown in Fig.4(B),the brush-coated PODPFβ-conformation devices show a turn-on voltage of 4.7 V,which is 2.04 V lower than that of the amorphous one. For comparison,the spin-coated PODPF devices show a rather high turn-on voltage of 7.5 V. The luminance of as-brushed device based onβ-conformation of PODPF shows clear increase with enlarging the voltage,achieving a maximum luminescence of 2600 cd/m2at 11 V and a maximum current efficiency of 1.53 cd/A at 5.6 V[Fig.4(C)],which is larger than that of other devices. The results indicated that the CFA-brushedβ-conformation devices exhibited clearly higher performance,compared to those of the CFA-brushed amorphous-phase devices and the spin-coated one[Fig.4(D)]. This is attributable to the high orientation of conjugated backbones and the large aggregation domain size. The electroluminescence(EL)spectra of the CFA-brushed PLEDs at the brushing speed of 800 μm/s are shown in Fig.4(E)and(F). EL spectra of CFA-brushed amorphous-phase device exhibited three emission bands at 436,464,and 488 nm. For theβ-phase device,EL spectra showed four emission bands at 452,484,512,and 544 nm. Importantly,the EL peak position hold constant with increasing the driving voltage,indicating the high stability of the EL emission for the PLED devices. Therefore,we believe this CFA-brushing method can be applied for fabricating polymer films with high orientation.

Fig.4 Schematic configuration of PLED device(A),brightness⁃voltage(B)and current effciency⁃voltage(C)plots for the PODPF devices prepared by both CFA⁃brushing and spin⁃coating methods,current density characteristics of the devices based on PODPF films(D),electro⁃luminescence(EL)spectra of the CFA⁃brushed PLEDs with amorphous⁃phase PODPF(E)and β⁃conformation PODPF(F)

4 Conclusions

In conclusion,a facile CFA-guided liquid transfer approach was demonstrated to develop highly oriented polymer thin films. Using the CFA,the PODPF solution was steadily transferred onto substrate in controllable manner,yielding oriented PODPF film on substrate. Then,the PODPF changed from the amorphous-phase to compactπ-πstackingβ-phase by a thermal annealing process atca.240 °C. Consequently,PODPF films with higher orientations and larger crystallized sizes were prepared. It is proposed that the CFA enables finely controlling the wetting and dewetting processes under directional stress,guiding the disorganized polymer transform into orientation. Taking advantage of the polymer film prepared by CFA-brushing method,a PLEDs device was developed,which exhibited higher current efficiency of 1.53 cd/A(5.6 V)compared with that of the spin-coated one. The CFA-guided liquid transfer offers a new applicable and facile approach in preparing high-quality polymer films.

The Supporting Information of this paper see http://www.cjcu.jlu.edu.cn/CN/10.7503/cjcu20200478.

This paper is supported by the National Key R&D Program of China(No.2018YFA0704801)and the National Natural Science Foundation of China(No.21872002).