Design and Lamination Process of Composite Fabric for Automobile

2020-02-01GUOYan郭嫣QIANGSheng强盛CUIWeiwei崔威威SONGMinfang

GUOYan(郭嫣),QIANGSheng(强盛),CUIWeiwei(崔威威),SONGMinfang

School of Textile Science and Engineering, Xi’an Polytechnic University, Xi’an 710048, China

Abstract: The composite fabric is a new type of automobile fabric in recent years. The three-layer composite fabric was made of different materials that were linen weaving fabric, knitting fabric and warp-knitted spacer fabric. Through testing performances of three different adhesives, the thermoplastic urethanes (TPU) hot melt powder was selected to adhere every fabric. Then, the laminating process was designed and applied. The optimized process conditions were following: the temperature was 150 ℃, the pressure was 2.0 N·cm-2, the time was 80 s, and the dosage of adhesive was 20 g·m-2. This new laminated fabric has multi-functions, such as comfortability, permeability and physic mechanical properties. This lamination process will be used to be the basis for the study of functional laminated car seat fabric.

Key words: lamination; composite; car seat fabric; process; peeling strength

Introduction

With the rapid development of the automotive industry, the production capacity for automotive textiles are constantly increasing[1-2]. The application of textile materials and functional automotive textiles have a great development prospect[3-4]. As one of the automotive materials,the car seat fabric is one of the widely used materials[5]. In order to improve property of car seat fabric and compound more function together, such as decoration and preservation type[6-7], this paper mainly studies laminated technology of car seat fabric, and tries to combine fabric of different structures and functions. The optimized process will be foundation of industrial production.

1 Experiments and Design

1.1 Laminated structural design

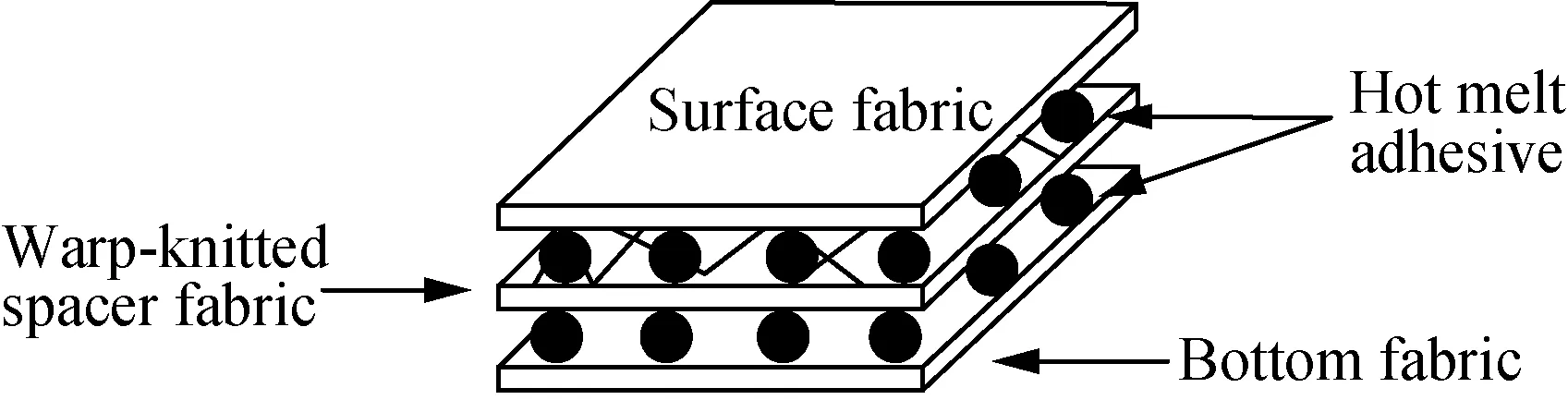

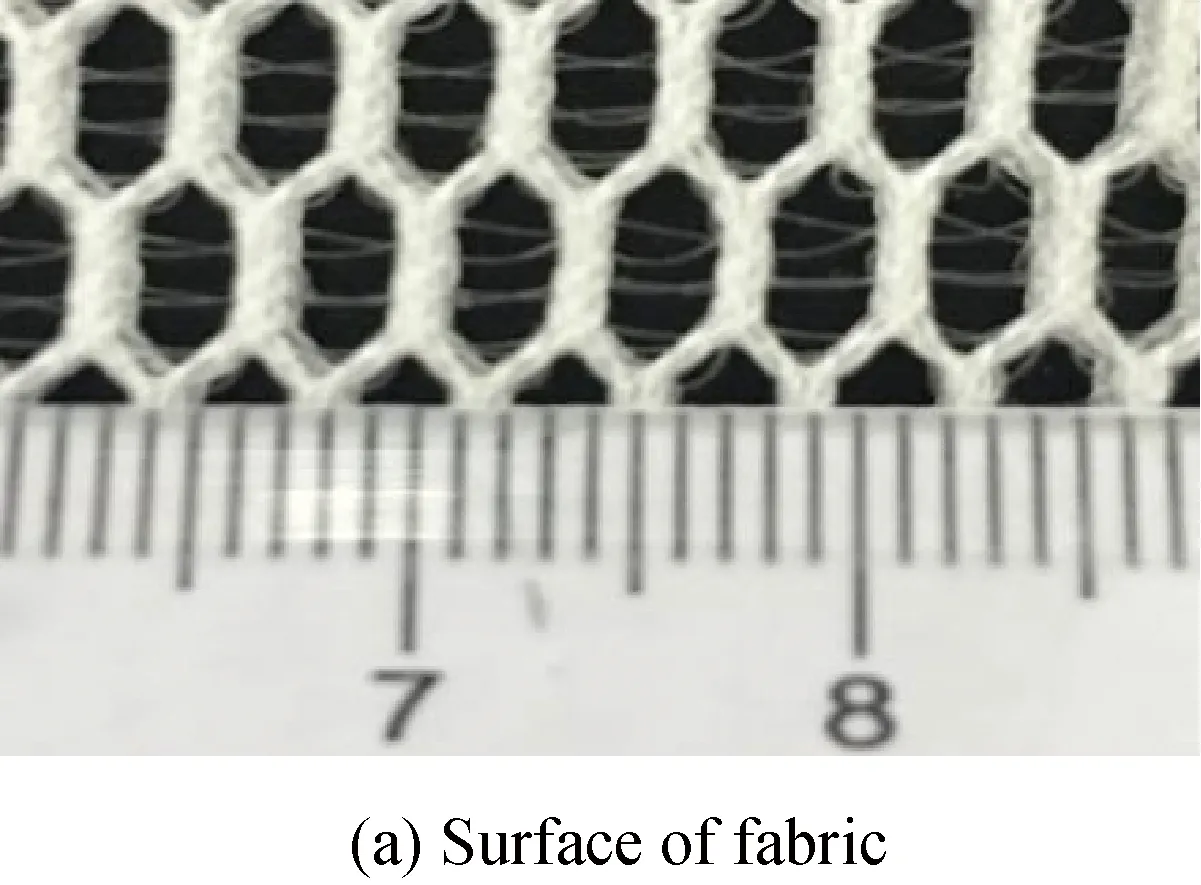

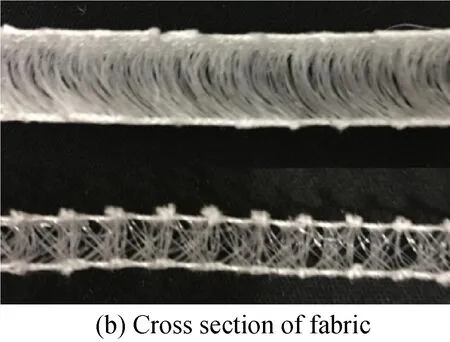

The colour of car seat fabric should be unified with the interior color of the car, which has a good decoration. At the same time, it should also have comfort, good resilience, shape-retention,etc. The requirements of environmental protection and flame retardant are also very important. Therefore, a variety of materials were composed in this laminated car seat fabrics. Surface fabric was covered in the seat and contacted with the body, so linen fabric by anti-flaming finish was the best chosen in permeability, comfortability, and micro-organism resistance. Middle layer has certain thickness, back elasticity and environmental protection,the warp-knitted spacer fabric was better than sponge, and replaced the sponge in this design[8-12]. The knitting fabric was selected to be bottom material, and its excellent extension could improve the cladding performance of the seat, and achieve the role of aesthetic preservation. Figure 1 was the diagrammatic sketch of the car seat composite fabric. Then, the three layers fabric was adhesive with hot melt powder through the composite process to become composite fabric. Figure 2 was the photoes of warp-knitted spacer fabric surface.

Fig. 1 Car seat fabric composite structure

Fig. 2 Photoes of warp-knitted spacer fabric

1.2 Materials and Methods

1.2.1Experimentalfabrics

The parameters of layer materials were shown in Table 1. No. 1 was on the surface layer of laminated fabric; No. 2 was the warp-knitted spacer fabric of the middle layer to increase elasticity of laminated fabric; No. 3 was knitting fabric of bottom layer.

1.2.2Instrumentsandmethods

(1) The instruments were used for experiments, such as the YG401C plate-type pressing machine(Nantong Hongda Experiment Instrument Co., Ltd., Nantong, China),the YG026-500 fabric strength tester(Changzhou Shuanggudunda Electromechanical Technology Co., Ltd., Changzhou, China), the YG461L type digital fabric permeability tester(Shanghai Biaozhuo Scientific Instrument Co., Ltd., Shanghai, China) and the STA449F3 synchronous heat analyzer (NETZSCH, Germany).

Table 1 Fabric technical parameters

(2) The peeling strength and permeability of laminated fabric were tested by standards FZ/T 01085—2018 Testing method for peeling strength of fusible interlinings and GB/T 5453—1997 Textiles-Determination of the permeability of fabrics to air.

(3) All of the permeability tests were measured in the way of surface fabric face up, because the laminated fabric was thicker and the opposite side of the measured breathability was different.

1.3 Laminated composite process

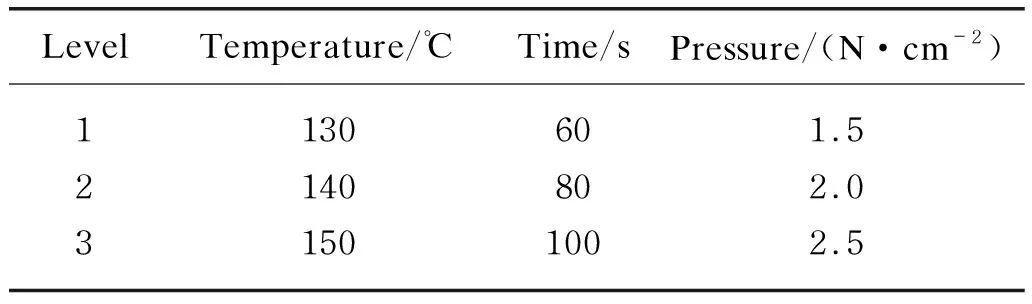

The orthogonal experimental schemes were designed and the factors were selected. When dosage of 20 g/m2hot melt adhesives was used, the selection factors of temperature, time and pressure were shown in Table 2.

Table 2 Experimental factors and levels of composite process

2 Results and Discussion

2.1 Performances of different adhesives

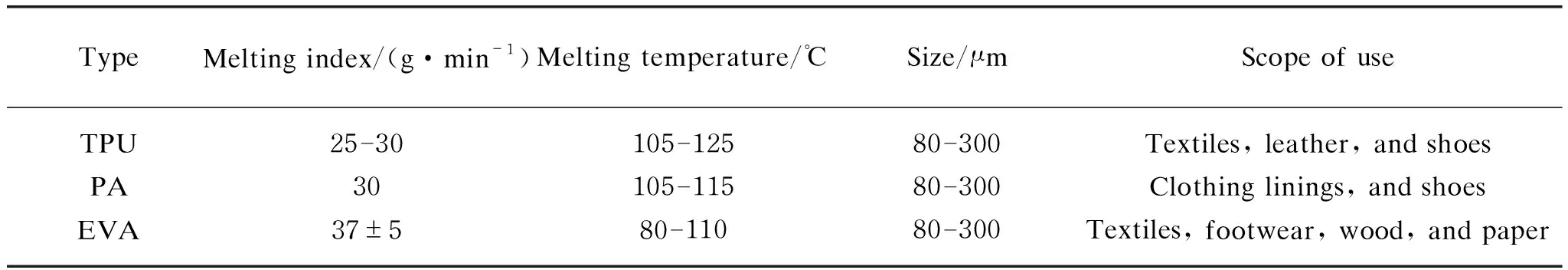

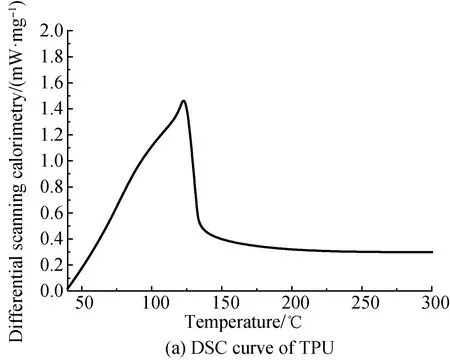

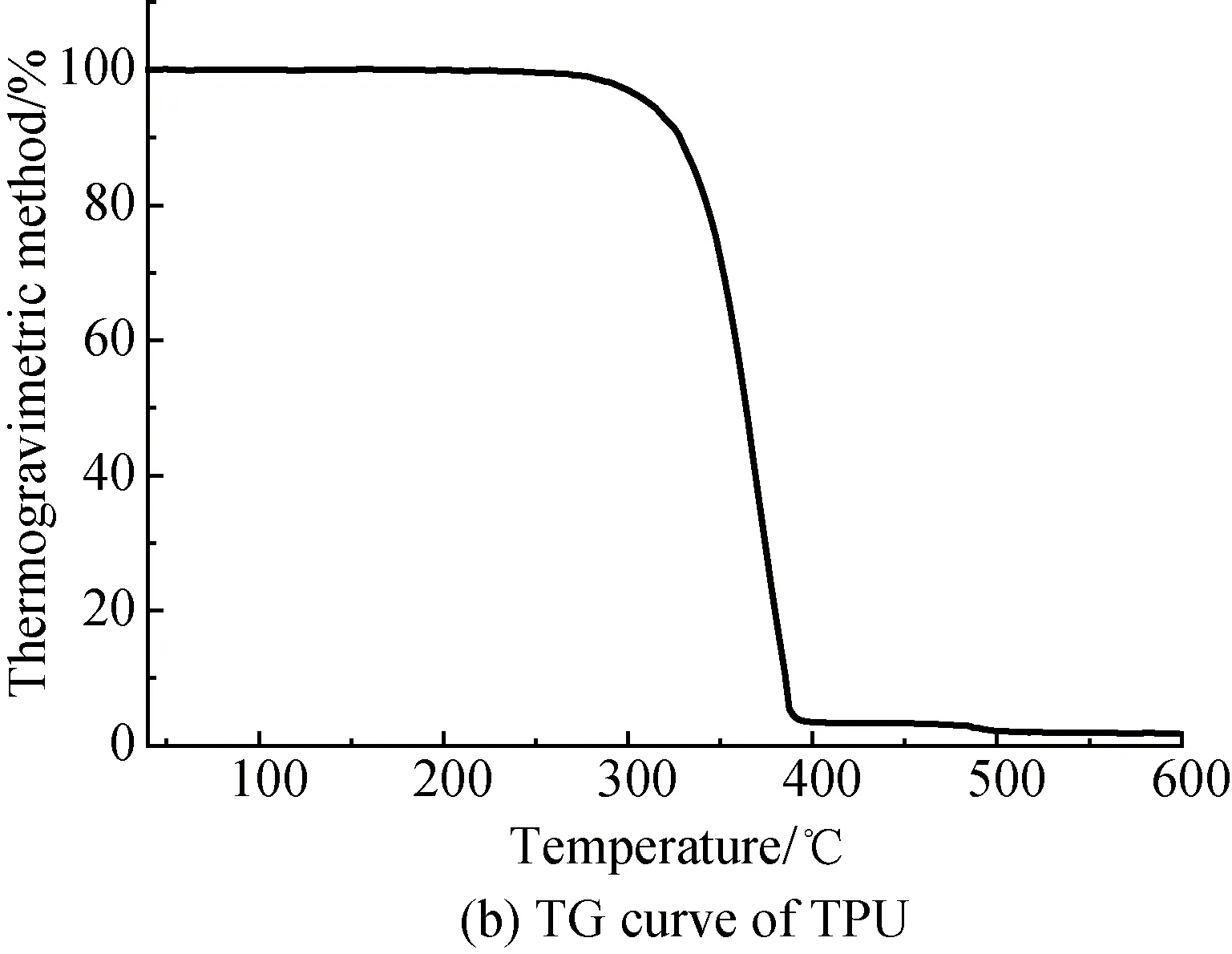

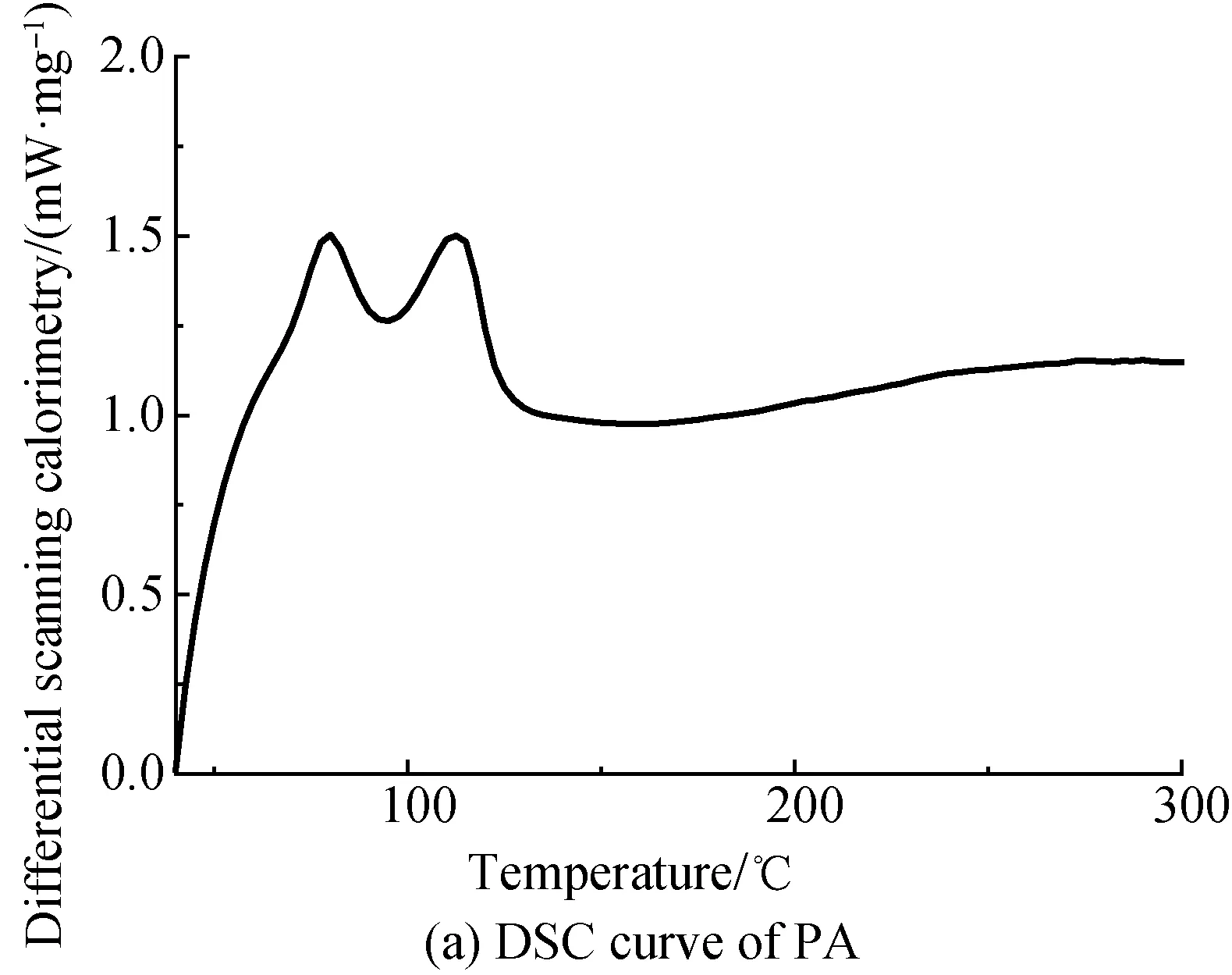

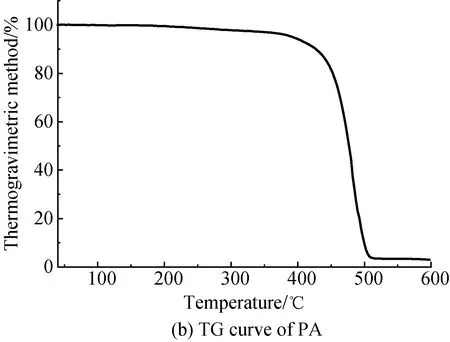

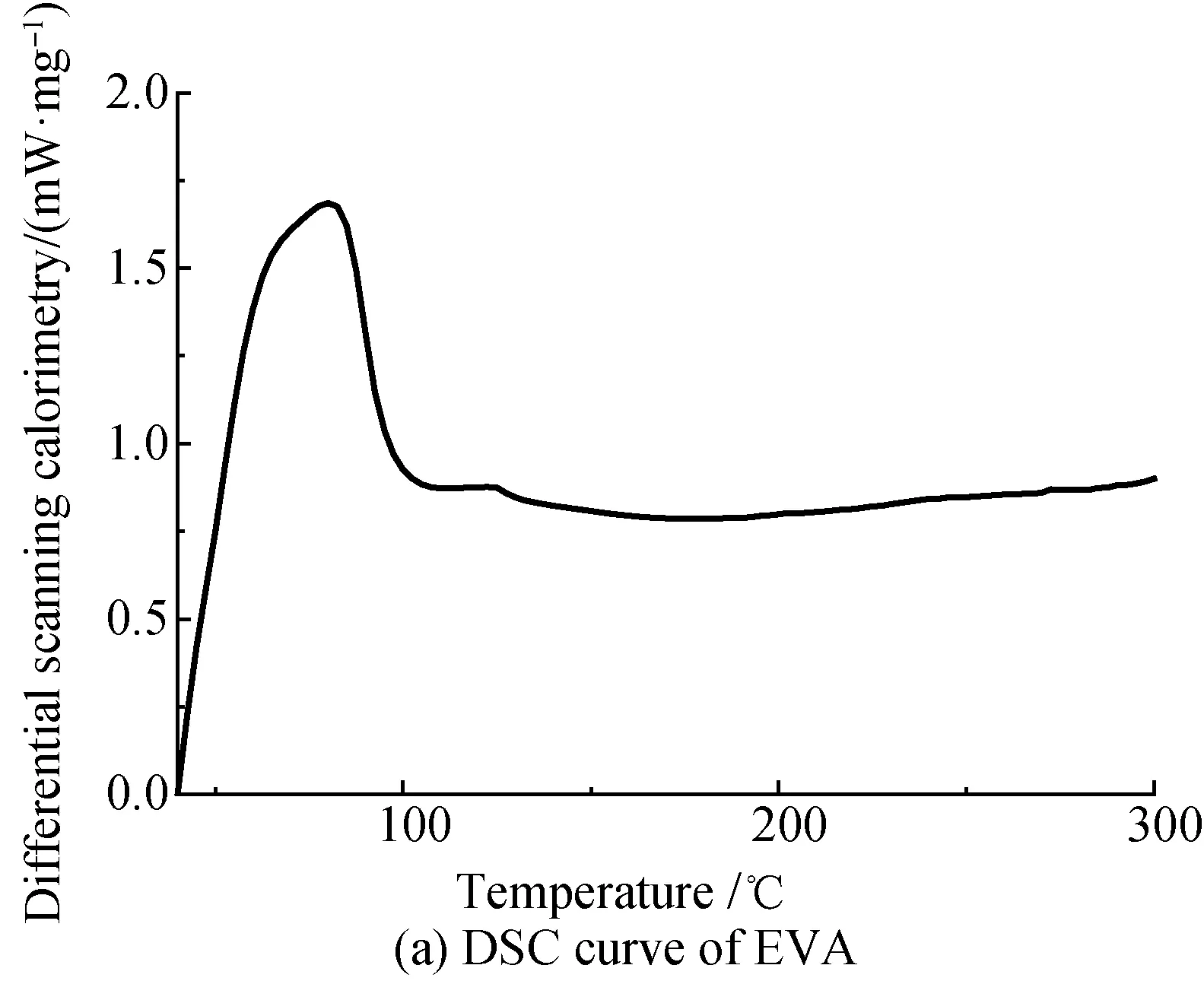

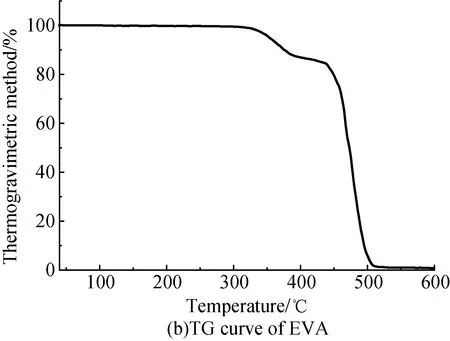

Three types of adhesives were used in this project, the properties were shown in Table 3, that were thermoplastic urethanes (TPU), polyamide (PA) and ethylene-vinyl acetate copolymer (EVA). Figures 3-5 were curves of the different adhesives in differential scanning calorimetry(DSC) and thermogravimetric method(TG ), and the melt condition was a heating rate of 10 ℃/min.

The melting temperature of TPU was 125 ℃, the DSC curve of PA had two peak value in 80 ℃ and 110 ℃, and the melting temperature of EVA was 80 ℃. From TG curves of different adhesives, TPU began to decompose at 260 ℃ and to completely decompose at 350 ℃; decomposition temperature of PA was 400 ℃ and completely decomposition temperature was 510 ℃; EVA began to decompose at 320 ℃, and to completely decompose at 510 ℃. So, TPU could be more adaptable to car conditions over 100 ℃, meanwhile, it has the characteristics of soft and elasticity. TPU has more advantages to be adhesive for polyester fabric and line fabric.

Table 3 Parameters of adhesives

Fig. 3 DSC and TG curves of TPU hot melt adhesives

Fig. 4 DSC and TG curves of PA hot melt adhesives

Fig. 5 DSC and TG curves of EVA hot melt adhesives

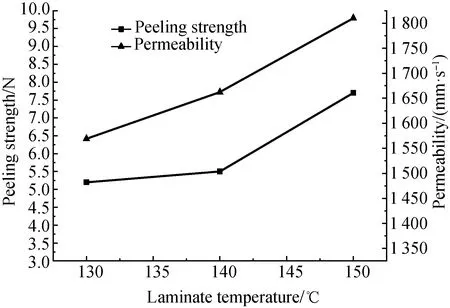

2.2 Effect of laminate temperature on peeling strength and permeability

With the increase of temperature, the peeling strength of laminated fabric increased strongly, which was due to the fact that the adhesives were fully melted and evenly immersed. At the same time, the permeability of laminated fabric also increased with the temperature increases, because the adhesive flowed into the laminated fabric and gathered less in the surface of the fabric (shown in Fig. 6).

Fig. 6 Varies of the peeling strength and permeability with temperature

2.3 Effect of laminate time on peeling strength and permeability

From Fig. 7, the peeling strength and permeability of laminated fabric were both well at 80 s, because at this time, the hot melt adhesive melted completely and covered on surface of the fabric.

Fig. 7 Varies of the peeling strength and permeability with time

2.4 Effect of laminate pressure on peeling strength and permeability

When the pressure was 2.0 N·cm-2, the peeling strength of composite fabric reached the best, but the permeability was best in 2.5 N·cm-2(shown in Fig. 8). When the pressure was over 2.0 N·cm-2, because the penetration and diffusion of adhesives were speedy, adhesives in surface of fabric were loss to make the peeling strength lower.

Fig. 8 Varies of the peeling strength and permeability with pressure

3 Comprehensive Evaluation of Laminated

Fabric

The parameters of optimization composite fabric were shown in Table 4. This composite fabric had high breaking strength, tearing strength and abrasion resistance, and also showed good physical and mechanical properties. Meanwhile, it could meet the requirements of the standard evaluation of car seat fabric, such as better air permeability, and enough peeling strength.

Table 4 Parameters of laminate fabric in optimization process

4 Conclusions

(1) Three hot melt powders, that was TPU, PA and EVA, were studied and analyzed in this paper. From curves of the DSC and TG, the melting points of the TPU, the PA, and the EVA were 125 ℃, 110 ℃ and 80 ℃, respectively. Considering the environment of automobile textile,the TPU was the best adhesive for laminated car seat fabric.

(2) When parameters of lamination were temperature 150 ℃, pressure 2.0 N·cm-2and time 80 s (in condition of dosage adhesive 20 g·m-2), laminated car seat fabric had excellent performances in permeability and physic mechanical properties.

(3) Through testing and evaluation, the parameters of laminated car seat fabric could meet requirements of automobile textiles completely.

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Physicochemical Properties of Poly (Vinyl Alcohol)/Chitosan/Soluble Starch Composite Hydrogel

- Synthesis, Structure and Properties of a Novel Copolymer with Photochromic and Photoluminescence Functions

- Dynamic Modeling of Variable Stiffness and Damping for Spatial Linkage Weft Insertion Mechanism with Clearance

- Energy-Delay Tradeoff for Online Offloading Based on Deep Reinforcement Learning in Wireless Powered Mobile-Edge Computing Networks

- Optimization Method of Bearing Support Positions in a High-Speed Flexible Rotor System

- Design and Application of Coordinator App Based on Needs Survey