进口管壁面轴向开槽消除轴流泵特性曲线驼峰

2018-08-10冯建军杨寇帆朱国俊罗兴锜李文锋

冯建军,杨寇帆,朱国俊,罗兴锜,李文锋

进口管壁面轴向开槽消除轴流泵特性曲线驼峰

冯建军,杨寇帆,朱国俊,罗兴锜,李文锋

(西安理工大学水利水电学院,西安 710048)

当轴流泵在小流量工况下运行时,由于叶轮进口的冲角增大,导致在叶轮内产生脱流等不稳定流动结构,降低泵的水力性能。该文采用计算流体动力学分析方法对轴流泵内部流场进行了研究,结果表明:该轴流泵的特性曲线存在明显的驼峰区域,在0.3到0.61倍最优流量工况区间,轴流泵的扬程和效率明显下降。在临界失速工况下(0.61倍最优流量工况),叶片吸力面前缘靠近轮缘处及叶片尾缘靠近轮毂处均出现了脱流;在深度失速工况下(0.45倍最优流量工况),脱流进一步发展,并与来流共同作用形成稳定的涡旋结构,阻塞整个流道。为了提高轴流泵在小流量工况下的水力性能,引入一种轴流泵进口管开槽技术,分析其对轴流泵内部流场的影响及驼峰的改善作用。结果表明:在小流量工况下,轴向开槽可以减小叶轮进口环量和冲角,可以减小叶片背部的脱流,轴流泵的驼峰得到明显的改善。开槽深度是改善轴流泵小流量工况下驼峰的重要因素之一,当槽深与叶轮直径比为0.02时,叶轮内的通道涡几乎完全消除,轴流泵深度失速工况点的扬程、效率分别提高了66%和32%,极大地改善了轴流泵的水力性能。沟槽数目越多,槽长越长,消除驼峰的能力越好,60个沟槽与2/3倍叶轮直径的槽长在其他参数相同的条件下消除驼峰的能力更强。该文可为避免轴流泵内部的失速流动以及消除水力性能曲线上的驼峰相关研究提供参考。

泵;计算机仿真;叶轮;计算流体动力学;轴流泵;驼峰;性能;轴向槽

0 引 言

轴流泵作为一种高比转速泵,有流量大和扬程低的特点,广泛应用在农业灌溉、防洪排涝、市政供水、水环境治理、电厂水循环以及船舶喷水推进器等领域[1-3]。轴流泵在小流量工况区域易产生驼峰,即在扬程和效率曲线上具有正斜率特性[4-10]。驼峰的出现即意味着运行工况存在严重的不稳定性,影响机组效率并造成大量能耗,更严重的会影响机组的运行安全性。

对于轴流泵驼峰的研究和改善方法,国内外学者开展了一定的研究。通过对轴流泵叶轮前后的速度场和靠近轮缘处的叶片压力分布开展研究,Toyokura[11]发现在最优工况点时叶轮内的流动较为平顺并且没有明显的回流现象,但随着流量降低,叶片发生失速时,叶轮处的径向速度突然增大,轴流泵的水力性能急剧下降。Goltz等[12]通过开展轴流泵的水力特性试验发现:临界失速工况下,在吸力面的前缘叶顶处和后缘靠近轮缘处分别捕捉到了回流结构;并且在深度失速工况下观测到流道中存在垂直叶片表面的通道涡。Fay[13]通过研究表明失速是由于叶片表面的流动分离引起的,当轴流泵的叶轮叶片数为3~4个时,失速团在叶轮通道中不发生转移,当叶轮叶片数为6片以上时,失速团会在叶轮通道中转移。仇宝云等[14]发现通过增设固定前导叶、选择适当的导水锥长度以及流道形线优化等方法,可以抑制和减弱叶片进口断面二次流,提高轴向流速均匀度,从而提高水泵运行效率和寿命。钱忠东等[15]发现冲角和尾部脱流是致使导叶部分水力损失增加的两大主要因素;可调式导叶可以通过调节角度显著地改善轴流泵导叶部分的流态,减小水力损失,提高泵的扬程和效率。此外,有学者借鉴压气机中扩大运行工况范围的“机匣”作用原理,在轴流泵进口管壁面采用轴向开槽的方法,有效消除了轴流泵扬程曲线上的驼峰[16-17]。而一些学者则在叶轮进口采用双进口喷嘴的方法,来减小轴流泵小流量工况下叶轮进口的预旋,从而抑制失速工况下叶轮叶顶附近的回流,改善叶轮入流条件进而提高水力性能[18-19]。

本文针对轴流泵小流量工况的流动特性开展研究,通过计算流体动力学分析揭示了不稳定工况下轴流泵内部失速流动的特征,并探究了轴流泵进口管内壁轴向开槽技术抑制泵内不良流动的机理,分析了泵进口管轴向开槽前后对失速流动的改善效果。同时,本文还进一步研究了不同槽的形状参数对轴流泵水力性能的影响,为避免轴流泵内部的失速流动以及消除水力性能曲线上的驼峰提供了有价值的参考。

1 数值计算方法

本文所选取的研究对象为比转速n=610的小型轴流泵。其叶轮直径1=300 mm,叶轮叶片数为6,扩压器导叶叶片数为11,设计转速=1450 r/min。该泵三维计算模型如图1所示,包含进口管、叶轮、扩压器及出口管。其中,进口锥管壁面采用轴向开槽,轴向槽的数量=60,均布角度=3°,槽长=200 mm[20]。

图1 轴流泵计算域和过流部件网格

采用ANSYS ICEM-CFD对各过流部件进行六面体网格划分。计算域网格总的单元数为706万。为了消除网格数对计算结果的影响,将计算网格加密到1 200万进行了结果对比。结果表明,当网格数从706万增加到1 200万,泵的计算扬程的相对变化仅为0.3%,效率变化约为0.4%。故认为采用网格数为706的网格可以得到网格无关解,因此采用该网格对轴流泵开展进一步的数值计算。

本文采用CFD商业软件ANSYS CFX-16来求解轴流泵内部三维湍流流场。边界条件为:在进口设置总压,出口给定质量流量,壁面边界均采用水力光滑的无滑移条件。对流项采用二阶中心差分方法进行离散,湍流模型选择壁面分离预测精度较高的SST湍流模型[21-23]。进口管与叶轮以及叶轮与扩压器交界面之间的数据传递采用Frozen-rotor交界面来实现,从而得泵内的稳态流场,从而计算泵的扬程和效率。同时,为了研究轴流泵的压力脉动,本文也对轴流泵内部的非定常流动进行了计算。在非定常计算中,轴流泵转动部件和固定部件之间的交界面采用Transient rotor-stator;时间步长设置为2.299×10-4s,对应转轮旋转2°;在每个步长内,设置收敛标准为最大残差小于10-3。

2 结果与分析

2.1 数值模拟的可靠性验证

图2为原始未开槽轴流泵模型数值模拟得到的扬程曲线和试验结果的对比。此轴流泵模型为一工业用泵,其扬程的试验数据由泵生产厂家据泵的出厂试验提供,试验数据与数值模拟结果列于表1。由图2可知,数值模拟得到的扬程与试验结果吻合较好,计算与试验得到的扬程曲线具有相同的变化规律且二者之间的偏差较小,最大偏差在3.5%以内,验证了CFD数值模拟的可靠性。

注:H为扬程;Hexp为试验所得最优工况点扬程;Q为流量;Qdes为最优工况点流量。

表1 轴流泵扬程误差分析 Table 1 Error analysis of axial pump head

2.2 进口管开槽对轴流泵水力性能的影响

为了研究泵进口管内壁面的开槽深度对驼峰的改善作用,本文对60个沟槽轴流泵模型进行了研究,应用进口管4种不同开槽深度的轴流泵进行水力性能对比。图3给出了进口管不同相对槽深的轴流泵扬程及水力效率曲线,其中相对槽深定义为槽深与叶轮直径1的比值。

由图3a可知,泵进口管未开槽即=0时,轴流泵驼峰现象十分严重[24-25],具体表现为在/des=0.61附近,扬程陡降40%,效率下降29.3%左右。采用相对槽深=0.013的轴向开槽进口管以后,轴流泵的驼峰得到明显改善,des=0.61附近的扬程陡降现象基本消失。当相对槽深增加到=0.02及=0.027时驼峰完全消除,此时轴流泵深度失速工况点的扬程、效率分别提高了约66%和32%。为了进一步分析具有沟槽特征的进口管对轴流泵能量特性的影响,对图3b中的轴流泵水力效率曲线进行分析发现,进口管内壁面开槽对最优工况附近的效率影响不大;但在小流量工况下,进口管内壁面开槽能够在一定程度上提高轴流泵的效率。随着进口管内壁面开槽深度的增加,在大流量工况下泵的效率相比于进口管未开槽的原始状态有所降低,且效率的降低幅度随着相对槽深的增大而增加。综合上述分析,选定相对槽深=0.02为本文最终方案。

注:Hdes为未开槽模型数值模拟所得最优工况点扬程。

2.3 进口管开槽改善驼峰的机理分析

开槽进口管通过对叶轮进口前的流体进行主动控制从而改善轴流泵的驼峰,为了分析进口管开槽对叶轮前来流的影响,探寻其改善驼峰的机理,在图4中分别给出了2种流量工况下进口管开槽和未开槽时叶轮进口的轴面速度分布和周向速度分布。变量Span为从轮毂到轮缘的相对叶高。由图4可知,在相同工况下,2种方案的叶轮进口轴面速度的分布规律基本相同,特别是在靠近轴流泵最优工况区,叶轮进口的轴面速度分布比较均匀,周向速度趋于0,同时,进口管开槽轴流泵叶轮进口的轴面速度明显大于未开槽的轴流泵,周向速度则正好相反。此外,通过分析不同流量工况下速度分布发现,当轴流泵运行在小流量工况下时,叶轮进口的轴面速度随半径分布不均匀,随着半径的增大,轴面速度先增大后减小至负值,导致水流在靠近管壁处出现回流,同时周向速度先减小后增大,在靠近轮缘处达到最大值[26-27]。通过上述分析可见,在小流量工况下,轴流泵的轴面速度减小,周向速度增大,根据轴流泵叶轮进口速度三角形可知进口冲角逐步增加,导致相邻两叶片间的脱流涡进一步累积、发展,最终堵塞了整个流道。

注:相对槽深为0.02,沟槽数目为60,下同。

叶轮内的能量损失和来流角有关[28],为了研究进口管开槽对轴流泵叶轮进口的液流角影响规律,分别对设计工况(des=1)、临界失速工况(des=0.61)、失速工况(des0.55)及深度失速工况(des=0.45)下轴流泵叶轮进口相对液流角进行了计算。图5列出了临界失速工况和失速工况下开槽和未开槽相对液流角变化规律。通过对比泵进口管开槽和未开槽的情况可以发现,进口管开槽使得靠近轮缘附近的相对液流角显著增加,最大增幅超过了40°,相对液流角大幅增加所带来的有益效果是减少了该处叶片进口的冲角,有效的遏制了叶片背部脱流[29],从而提高了轴流泵在小流量工况下的扬程,抑制驼峰。但在临界失速时,进口管开槽后使得叶片进口靠近轮毂处的相对液流角反而减小,说明进口管开槽能很好地抑制轮缘处的冲角,但开槽对靠近轮毂处流动状态的改善作用十分有限。

图5 不同相对叶高下叶轮进口相对液流角

图6分别给出了失速工况(/des=0.55)不同相对叶高截面处的速度流线图。由图6可知,当Span=0.8时,叶轮流道内出现双排涡,靠近叶轮进口处的涡顺时针旋转,靠近出口的涡呈逆时针旋转,旋涡几乎堵塞了整个流道。当Span=0.85时,叶轮出口处未发现涡旋结构,取而代之的是一条出流和回流的分界线,此时叶轮进口处旋涡结构较小,更贴近于叶片进口。当截面进一步扩大,在Span=0.9时,叶轮进口涡缩小,回流进一步加大,并在叶轮进口处受来流冲击作用,改变流动方向,向下一级叶轮通道流动。开槽以后,由图6b、6d、6f可知,叶轮进口管壁面开槽改变了来流方向,增大了叶轮轮缘处进口的流速,能够有效的消除叶轮流道中的通道涡。

图7为深度失速工况(/des=0.45)下,叶轮叶片表面不同叶高上的压力分布对比。表示从叶片头部到尾部的无量纲相对弦长。由图7可知,在深度失速工况下,除在靠近轮毂处叶片背面出口处压力变化较大外,其他位置叶片正背面的压力分布比较均匀,进口管开槽后,叶轮叶片正背面的压力特别是靠近叶片出口处叶片正背面的压力提升都十分明显。而叶片中部压差被进一步增大,增加了叶片中部的负载,这也表明叶片转换能量的能力得到提升,提高了轴流泵的扬程。

图6 不同叶轮截面的流线分布(Q/Qdes=0.55)

图7 Q/Qdes=0.45时,叶轮叶片表面压力分布

2.4 进口管开槽对轴流泵压力脉动特性的影响

为了研究进口管开槽对轴流泵压力脉动的影响,对该轴流泵模型进行了非定常计算,并在叶轮进口沿径向设置3个监控点(如图8所示),监控压力脉动特性。其中P1靠近轮毂,P2处于半叶高位置,P3靠近轮缘。

注:P1靠近轮毂;P2处于半叶高位置;P3靠近轮缘。

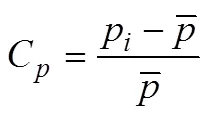

采用式(1)定义的无量纲压力脉动系数C来表示压力脉动[7]。

图9给出了设计工况下叶轮进口截面上3个监控点上的压力脉动系数频域图,其中为捕捉到的频率和叶轮转频的比值。由图9可知,设计工况下的压力脉动幅值由轮毂到轮缘依次增大,压力脉动的主频为6倍转频,即叶片通过频率。这充分说明在最优工况下,2种方案下叶轮进口前的压力脉动主要受叶轮转动影响[30-32]。从监测点P1和P2可以看出在2种方案下压力脉动幅值变化不大,说明在最优工况下,进口管开槽对远离轮缘区域压力脉动影响不大。进口管开槽对靠近轮缘的监测点P3的压力脉动幅值影响较大,进口管开槽方案下的最大压力脉动幅值约为未开槽的5倍左右,因此进口管开槽增大了叶轮转频下的压力脉动幅值。

图10给出了失速工况下叶轮进口截面压力脉动频域图。由图10可知,在失速工况下,进口管开槽的轴流泵的压力脉动主频包含叶片通过频率和3.5倍转频下的脉动值;与之对应的是进口管未开槽的情况下,压力脉动的主频为6倍转频。通过对比发现,进口管开槽增加了高频脉动的幅值。但值得注意的是,除靠近轮缘的监测点P3外,监测点P1和P2的低频压力脉动幅值有所降低。对比图10,在最优工况下和失速工况下,监测点P1和P2上的压力脉动幅值变化不大,压力脉动幅值的最大值均低于0.3。但由于监测点P3靠近叶轮进口壁面,而每个叶轮叶片通道对应10个轴向槽,叶片在高速转动过程中与轴向槽形成动静干涉作用[33],使得叶轮进口靠近轮缘处的压力脉动急剧增大。因此,在使用壁面开槽来抑制轴流泵的驼峰时,尽量使用较少的轴向槽数,以便减少靠近壁面的压力脉动幅值。

图9 Q/Qdes=1时,设计工况下叶轮进口压力脉动频谱

图10 Q/Qdes=0.55时,失速工况下叶轮进口压力脉动频谱

图11中给出了不同开槽参数下、在驼峰区域附近轴流泵扬程的对比。由图11可知,减小开槽个数在一定程度上降低了开槽的效果,达不到完全消除驼峰的目的。原因是叶轮进口的周向速度没有能降低到消除驼峰的程度。此外,将开槽长度1从2/3降低到1/3时,对轴流泵驼峰的改善效果略有降低,因此,60个沟槽与2/3倍叶轮直径的槽长在其他参数相同的条件下消除驼峰的能力更强。由此可见,合理选择轴向槽的参数对提高轴流泵小流量工况的水力性能、改善驼峰非常重要,值得进一步研究。

注:K为相对槽深,K=h/D1, h为槽深,D1为叶轮直径;Z为沟槽数目;L为沟槽长度,L/D1为相对槽长。

3 结 论

本文采用数值仿真的方法,研究了轴流泵进口轴向开槽对轴流泵水力特性上的驼峰的改善作用,探究了轴向开槽抑制叶轮内流动失速的机理,具体结论如下:

1)在0.61倍最优流量工况点(有效最高点),轴流泵的扬程和效率存在一个突降,分别下降了40%和29.3%,从而造成扬程曲线存在明显的驼峰现象。在小流量工况下,叶轮进口的轴面速度降低,周向速度增加,水流在叶轮叶片头部的冲角增大,导致在叶轮叶片背面脱流严重,并产生回流。回流在来流的冲击作用下形成了回流涡,堵塞了整个流道,导致扬程急剧下降。

2)采用了进口段壁面轴向开槽的方法来抑制叶轮内的流动失速。当相对槽深为0.02时,轴向开槽增加了轴流泵叶轮叶片进口处的轴向速度,改善了轴流泵叶轮叶片进口处的水流冲角,有效的抑制叶轮进口预旋回流和通道涡的产生,对消除轴流泵驼峰、提高轴流泵驼峰区效率起到积极作用。

3)在0.55倍最优流量工况点,轴向开槽提高了叶轮叶片正背面的压力,这种现象在靠近叶片出口更加明显。在叶片中部正背面压差被进一步拉大,导致叶片中部载荷增加,从而提高了轴流泵的扬程。

4)在叶轮的旋转过程中,叶轮叶片和进口管轴向槽流体之间的相对运动造成流体的动静干涉效应,在一定程度上增加了轴流泵叶轮内高频压力脉动的幅值,且引入了多种轴流泵转频倍频,但同时抑制了叶轮内低频压力脉动的产生。

[1] 何川. 泵与风机(第四版)[M].北京:中国电力出版社,2014.

[2] 洛马金(苏). 梁荣厚译. 离心泵与轴流泵[M]. 北京:机械工业出版社,1978.

[3] 关醒凡. 现代泵理论与设计[M]. 北京:中国宇航出版社,2011.

[4] 王丽慧,施伟,沈昌荣,等. 立式轴流泵装置模型水力性能数值分析及预测[J]. 排灌机械工程学报,2016,34(9):767-773. Wang Lihui, Shi Wei, Shen Changrong, et al. Numerical analysis and prediction of hydraulic performance of vertical axial-flow pump system model[J]. Journal of drainage and irrigation machinery engineering, 2016, 34(9): 767-773. (in Chinese with English abstract)

[5] 马皓晨,丁荣,杨东升. 低比转数离心泵驼峰现象的CFD分析[J]. 流体机械,2013(12):43-47.

Ma Haochen, Ding Rong, Yang Dongsheng. CFD research on hump phenomenon of low specific speed centrifugal pump[J]. Fluid Machinery, 2013(12): 43-47. (in Chinese with English abstract)

[6] 刘君,段宏江,刘立峰,等. 低扬程立式轴流泵装置模型试验研究[J]. 水泵技术,2011(6):1-6.

[7] 郑源,陈宇杰,张睿,等. 轴流泵失速工况下非定常流动特性研究[J]. 农业机械学报,2017,48(7):127-135.

Zheng Yuan, Chen Yujie, Zhang Rui, et al. Analysis on Unsteady stall flow characteristics of axial-flow pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 127-135. (in Chinese with English abstract)

[8] 冒杰云,袁寿其,张金凤,等. 低比转速离心泵驼峰工况附近内部流动特性分析[J]. 排灌机械工程学报,2014,33(4):283-289.

Mao Jieyun, Yuan Shouqi, Zhang Jinfeng, et al. Analysis of inner flow characteristics in low specific speed centrifugal pump around hump conditions[J]. Journal of Drainage and Irrigation Machinery Engineering, 2014, 33(4):283-289. (in Chinese with English abstract)

[9] 郑源,茅媛婷,周大庆,等. 低扬程大流量泵装置马鞍区的流动特性[J]. 排灌机械工程学报,2011,29(5):369-373.

Zheng Yuan, Mao Yuanting, Zhou Daqing, et al. Flow characteristics of low-lift and large flow rate pump installation in saddle zone[J]. Journal of Drainage and Irrigation Engineering, 2011, 29(5): 369-373. (in Chinese with English abstract)

[10] 张睿. 轴流泵失速和空化流动特性及其性能改善研究[D].上海:上海大学,2014. Zhang Rui. Research on the Stall and Cavitation Flow Characteristics and the Performance Improvement of Axial-flow Pump[D].Shanghai: Shanghai University, 2014. (in Chinese with English abstract)

[11] Toyokura T. Studies on the characteristics of axial-flow Pumps: Part 1, General tendencies of the characteristics of pumps[J]. Bulletin of JSME, 1961, 4(14): 287-293.

[12] Goltz I, Kosyna G, Stark U, et al. Stall inception phenomena in a single-stage axial-flow pump[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2003, 217(4): 471-479.

[13] Fay A. Analysis of separated flows in hydro machines[R]. 6th IASME/WSEAS International Conference, 2008.

[14] 仇宝云,林海江,黄季艳,等. 大型立式轴流泵叶片进口流场及其对水泵影响研究[J]. 机械工程学报,2005,41(4):28-34.

Qiu Baoyun, Lin Haijiang, Huang Jianyan, et al. Study on flow field in blade inlet of large vertical axial-flow pump and its influence on pump [J] .Journal of Mechanical Engineering, 2005, 41(4): 28-34. (in Chinese with English abstract)

[15] 钱忠东,王焱,郑彪,等. 可调导叶式轴流泵水力特性数值模拟[J]. 水力发电学报,2011,30(2):123-127.

Qian Zhongdong, Wang Yan, Zheng Biao, et al. Numerical simulation and analysis of performance of axial flow pump with adjustable guide vanes[J]. Journal of Hydroelectric Engineering, 2011, 30(2): 123-127. (in Chinese with English abstract)

[16] Goltz I, Kosyna G, Stark U, et al. Eliminating the head instability of an axial-flow pump using axial grooves[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2012, 227(2): 206-215.

[17] 张睿,陈红勋. 改善失速工况下轴流泵水力性能的研究[J]. 水力发电学报,2014,33(3):292-298.

Zhang Rui, Chen Hongxun. Study on the improvement of hydrodynamic performance of axial-flow pump at stall condition[J]. Journal of Hydroelectric Engineering, 2014, 33(3): 292-298. (in Chinese with English abstract)

[18] Flores P, Kosyna G, Wulff D. Suppression of performance curve instability of an axial-flow pump by using a double-inlet-nozzle[J]. International Journal of Rotating Machinery, 2014, 2008: 7.

[19] Hans Josef Dohmen, Friedrich-Karl Benra, Sven Brinkhorst. Improvement of axial-flow pump part load behavior by a double inlet nozzle [C]// ASME 2012 Fluids Engineering Summer Meeting, 2012:479-489.

[20] Goltz I, Kosyna G, Wulff D, et al. Structure of the rotor tip flow in a highly loaded single-stage axial-flow pump approaching stall: Part II-Stall Inception-Understanding the mechanism and overcoming its negative impacts[C]// ASME 2004 Heat Transfer/Fluids Engineering Summer Conference, 2004: 301-306.

[21] Menter F R. Two-equation eddy-viscosity turbulence models for engineering applications [J]. Aiaa Journal, 1994, 32(8): 1598-1605.

[22] 王德军,周惠忠,黄志勇,等. 对旋式轴流泵全流道三维定常紊流场的数值模拟[J]. 清华大学学报:自然科学版,2003,43(10):1339-1342.

Wang Dejun, Zhou Huizhong, Huang Zhiyong, et al. 3-D steady turbulence flow numerical simulation on the full passage of a counter-rotating axial flow pump[J]. Journal of Tsinghua University: Science and Technology, 2003, 43(10): 1339-1342. (in Chinese with English abstract)

[23] 张德胜,吴苏青,施卫东,等. 轴流泵小流量工况条件下叶顶泄漏空化特性[J]. 农业工程学报,2013,29(22):68-75.

Zhang Desheng, Wu Suqing, Shi Weidong, et al. Characteristics of tip leakage vortex cavitation in axial flow pump at small flow rate condition[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(22): 68-75. (in Chinese with English abstract)

[24] 张海胜,徐建叶,陈宇杰,等. 立式轴流泵水力不稳定工况流场数值预测[J]. 水泵技术,2016(2):29-32.

Zhang Haisheng, Xu Jianye, Chen Yujie, et al. Numerical prediction of flow field in vertical axial flow pump with unstable hydraulic conditions [J]. Water Pump Technology, 2016(2): 29-32. (in Chinese with English abstract)

[25] 姚洋阳. 水泵水轮机泵工况驼峰特性流动机理数值研究[D]. 北京:清华大学,2015.

Yao Yangyang. Hydrodynamic Mechanism Analysis of the Pump Hump District For a Pump-Turbine[D]. Beijing: Tsinghua University, 2015. (in Chinese with English abstract)

[26] Benra F K, Dohmen H J, Schmidt M. Flow phenomena in a highly-loaded single-stage axial-flow pump: Comparison of experimental and numerical results[C]// ASME/JSME 2007, Joint Fluids Engineering Conference, 2007: 979-984.

[27] Kosyna G, Goltz I, Stark U. Flow structure of an axial-flow pump from stable operation to deep stall[C]// ASME 2005 Fluids Engineering Division Summer Meetin, 2005: 1389-1396.

[28] 朱俊华. 轴流泵叶片外缘液流角∞对轴流泵性能的影响[J]. 水泵技术,1995(6):3-6.

Zhu Junhua. Effect of the flow angle∞at the outer edge of axial flow pump on the performance of axial-flow pump[J]. Pump Technology, 1995(6): 3-6. (in Chinese with English abstract)

[29] 王凡,钱忠东,郭志伟,等. 可调导叶式轴流泵压力脉动数值分析[J]. 农业机械学报,2017,48(3):119-123.

Wang Fan, Qian Zhongdong, Guo Zhiwei, et al, Pressure oscillations prediction of axial flow pump with adjustable guide vanes[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 119-123. (in Chinese with English abstract)

[30] 王福军,张玲,张志民. 轴流泵不稳定流场的压力脉动特性研究[J]. 水利学报,2007,38(8):1003-1009.

Wang Fujun, Zhang Ling, Zhang Zhimin. Analysis on pressure fluctuation of unsteady flow in axial-flow pump[J]. Journal of Hydraulic Engineering, 2007, 38(8): 1003-1009. (in Chinese with English abstract)

[31] 施卫东,冷洪飞,张德胜,等. 轴流泵内部流场压力脉动性能预测与试验[J]. 农业机械学报,2011,42(5):44-48.

Shi Weidong, Leng Hongfei, Zhang Desheng, et al. Performance prediction and experiment for pressure fluctuation of interior flow in axial-flow pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(5): 44-48. (in Chinese with English abstract)

[32] 张德胜,施卫东,李通通,等. 轴流泵叶轮出口尾迹区非定常压力和速度场特性[J]. 农业工程学报,2012,28(17):32-37.

Zhang Desheng, Shi Weidong, Li Tongtong, et al. Property of unsteady pressure and meridional velocity in wake region of axial-flow pump impeller[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(17): 32-37. (in Chinese with English abstract)

[33] 张德胜,耿琳琳,施卫东,等. 轴流泵水力模型压力脉动和振动特性试验[J]. 农业机械学报,2015,46(6):66-72.

Zhang Desheng, Geng Linlin, Shi Weidong, et al. Experimental investigation on pressure fluctuation and vibration in axial-flow pump model[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(6): 66-72. (in Chinese with English abstract)

Elimination of hump in axial pump characteristic curve by adopting axial grooves on wall of inlet pipe

Feng Jianjun, Yang Koufan, Zhu Guojun, Luo Xingqi, Li Wenfeng

(,,710048,)

Axial flow pumps are widely utilized for transporting fluid with large flow rates. The internal flow field is extremely complex and fully turbulent. When an axial flow pump operates at small flow rate, the incidence angle at the impeller leading edge will increase because of the decreasing meridional velocity. Rotating stall may occur when the incidence angle reaches a threshold, which will reduce greatly the delivery head of the pump and produce a hump in the pump performance curve. The hump phenomenon is a source of instability for the pump operation, which will normally limit the safe operating range of an axial flow pump. Therefore, it is very important to understand the flow behavior inside the pump during the range corresponding to the hump, so as to find a way to improve the flow condition. In this paper, the commercial software ANSYS CFX-16 was adopted to calculate the three-dimensional turbulent flow in an axial flow pump with a specific speed of 610 at different flow conditions. The pump impeller has an outer diameter of 0.3 m, with 6 three-dimensional blades, and the diffuser has 11 two-dimensional vanes. The computational meshes were created by ICEM-CFD (integrated computer engineering and manufacturing code for computational fluid dynamics) in structured format, andSST turbulence model was chosen for the unsteady simulations. The obtained results show that there is an obvious hump in the performance curve of the axial flow pump, occurring in the flow range of between 30% and 61% design flow rate. In the critical stall condition (61% design flow rate), flow separations have been observed at the leading edge of the impeller blade near the shroud and at the blade trailing edge near the hub. Under a deep stall condition (45% design flow rate), the flow is seriously developed and combined with the incoming flow to form a stable vortex structure that blocks the whole flow passage. In order to improve the hydraulic performance of the axial flow pump under small flow conditions, axial grooves were applied to the wall of the pump inlet pipe. The effects of axial grooves on the internal flow field and pump performance curves have been examined in detail, and different configurations of the grooves have also been tested, in order to find the best one for improving the pump performance. The results show that under the condition of small flow rates, the axial grooves can effectively reduce the inlet circulation and the attack angle at the leading edge of the impeller as well. As a result, the back flow on the suction side of the impeller has been reduced. Consequently, the unstable hump phenomenon in the performance curve of the axial flow pump has been eliminated. At the same time, it is found that the relative groove depth is one of the most important factors to improve the stability in performance curves for the axial flow pump under small flow rate conditions. When the groove depth reaches 1/50 of the impeller diameter with the axial length being 2/3 of the impeller diameter, the axial grooves increase the axial velocity and the relative flow angle near the shroud of the impeller. As a consequence, both the inlet circulation and the attack angle of the inlet of impeller have been greatly reduced. The backflow occurring near the impeller leading edge is obviously eliminated, the channel vortex is almost eliminated, and the hump phenomenon of the axial flow pump has been removed. However, the pressure fluctuation in the impeller has been magnified by the axial grooves, caused by the rotor-stator interaction effects between the rotating impeller blades and stationary axial grooves. In addition, the introduction of axial grooves has introduced some high-order harmonics of the impeller rotation frequency and depressed low-order harmonics to the frequency spectrum of unsteady pressure fluctuations.

pumps; computer simulation; impellers;computational fluid dynamics; axial flow pump; hump; performance; axial grooves

冯建军,杨寇帆,朱国俊,罗兴锜,李文锋. 进口管壁面轴向开槽消除轴流泵特性曲线驼峰[J]. 农业工程学报,2018,34(13):105-112.doi:10.11975/j.issn.1002-6819.2018.13.013 http://www.tcsae.org

Feng Jianjun, Yang Koufan, Zhu Guojun, Luo Xingqi, Li Wenfeng. Elimination of hump in axial pump characteristic curve by adopting axial grooves on wall of inlet pipe[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(13): 105-112. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.13.013 http://www.tcsae.org

2017-12-29

2018-04-04

国家自然科学基金(51679195;51339005);陕西省自然科学基础研究计划(2018JM5102)

冯建军,教授,博士生导师,研究方向为流体机械流动理论及优化设计。Email:jianjunfeng@xaut.edu.cn

10.11975/j.issn.1002-6819.2018.13.013

TH312

A

1002-6819(2018)-13-0105-08