拖拉机转向轮转角位移式和四连杆式间接测量方法对比试验

2017-10-13胡书鹏尚业华赵春江付卫强

胡书鹏,尚业华,刘 卉,李 由,赵春江,付卫强

拖拉机转向轮转角位移式和四连杆式间接测量方法对比试验

胡书鹏1,2,尚业华2,3,刘 卉1,李 由2,3,赵春江2,3,付卫强2,3※

(1. 首都师范大学信息工程学院,北京 100048; 2. 北京农业信息技术研究中心,北京 100097; 3. 国家农业信息化工程技术研究中心,北京 100097)

针对车轮转角直接测量法在工程实践中角度传感器安装困难且转轴易断裂的现象,结合车轮转向过程,提出了位移式间接转角测量法和四连杆式间接转角测量法。依据位移式和四连杆式2种间接测量方法原理,分别建立转角测量模型,以雷沃M800型拖拉机为基础,构建自动导航试验平台,通过转角测量试验、沥青路面与农田环境下的导航精度对比试验,分析四连杆式间接测量法、位移式间接测量法和直接测量法3种方法的应用效果。转角测量对比试验结果表明,3种方法的角度值最大误差为0.081°,平均误差分别为0.061°、0.014°和0.017°,小于传感器的测量精度0.088°,3种测量方法测量的测量精度一致。通过沥青路面与农田环境2种地况试验测试,沥青路面上和农田环境下,3种方法的横向偏差平均值的最大值分别为0.235 9、0.364 5、0.498 4 cm,试验表明3种测量方法的导航精度一致。相对于位移式间接转角测量法和直接测量法,在沥青路面上和农田环境下,四连杆式间接测量法导航精度标准差最小,分别为0.890 4和1.297 5 cm。四连杆式间接转角测量法所采用的四连杆式角度传感器安装简便、易于防护,无摩擦损耗,可代替直接转角测量法,应用于实践中。

农业机械;转向;模型;自动导航;转角测量;位移;四连杆;导航精度

0 引 言

随着精准农业的发展,拖拉机自动导航系统作为农业智能装备的重点,应用越来越广泛[1-2]。拖拉机自动导航系统是通过控制转向油缸活塞杆的位置,实现拖拉机运动轨迹控制。通常车轮对中时,车轮轴线与车身中轴线平行。当车轮转动后,车轮轴线与车身中轴线的夹角即为车轮转角。车轮转角测量作为自动导航系统自动转向单元的一部分,是影响自动导航精度的重要因素之一[3-4]。

国内外研究人员采用了不同的技术手段进行拖拉机自动导航系统车轮转角的测量。Xiang等[5-8]通过电位计测量转向节旋转角度,获取车轮转角,Lee等[9-11]采用绝对式编码器测量车轮转角,Hu等[12-13]通过位移式传感器测量转向油缸行程,推算车轮转角。冯朝印等[14-17]采用电阻式角度传感器,黎永键等[18-19]采用KMA199型磁敏电阻式角度传感器测量车轮转角,尤文宽等[20-21]采用霍尔角位移传感器测量转向轮转角值,任文涛等[22-24]采用位移式传感器测量车轮转角,王鹤等[25-27]采用将GAS60型角度传感器安装在前桥上,并通过连杆与转向节连接,实现车轮转角测量。据此,常用的车轮转角测量方法有角度传感器直接测量法、位移式间接转角测量法和四连杆式间接转角测量法等3种。但在科研试验与工程实践中发现,角度传感器安装困难且转轴易断裂,编码器的分辨率较低,磁阻式角度传感器受气隙磁场不均匀影响很大[15]。

本文以雷沃M800型拖拉机为研究平台,选择霍尔角度传感器作为角度传感器直接法的转角测量设备;选择直线位移传感器和四连杆式角度传感器作为间接转角测量设备,根据2种传感器测量转角的原理,分别建立转角测量模型,设计对比试验比较直接测量法和2种间接测量法时的测量精度,并通过田间试验对比其用于拖拉机自动导航系统对导航精度的影响。

1 车轮转角测量法

1.1 角度传感器直接测量法

将角度传感器与转向节立轴同轴安装,使角度传感器转轴与转向节同步旋转。由于转向节相对于车轮有一定倾斜(图1),从车辆前方看车轮,转向节与车轮中轴线有一个夹角,即为转向节侧倾角;从车辆侧面看车轮,转向节与车轮轴线有一个夹角,即为转向节后倾角。

转向节倾斜使得转向节旋转角度与车轮实际转角值不相等,其车轮-转向节转角的关系模型如下[26-27]

式(2)即为角度传感器直接测量法的角位移量与车轮转角关系式,其中和值可从拖拉机手册中查到,值由角度传感器测量得到。

1.转向节 2.导向轮

1.Knuckle 2.Guide wheel

注:为内倾角,(°);为后倾角,(°)。

Note:represents camber, (°);represents caster angle, (°)。

图1 车轮转向节内倾角和后倾角

Fig.1 Wheel knuckle caster angle and inclination angle

1.2 位移式间接转角测量法

直线位移传感器与转向油缸并列安装,其安装示意图如图2a所示。

1.转向节臂 2.转向节 3.前桥 4.转向油缸 5.直线位移传感器

1.Knuckle arm 2.Kunckle 3.Front axle 4.Steering cylinder 5.Displacement sensor

注:1为转向节中心点到转向油缸活塞杆固定点长度,mm;2为转向节中心点到转向油缸固定点的长度,mm;3为车轮对中时的转向油缸长度,mm;为转向油缸活塞杆位移量,mm;为车轮对中时,转向节臂与转向节中心点到转向油缸固定点连线之间的夹角,(°);为转向节旋转角度,(°)。

Note:1represents length of knuckle center point to steering cylinder piston rod fixed point, mm;2represents length of knuckle center point to steering cylinder fixed point, mm;3represents steering cylinder when wheel is centered, mm;represents displacement of steering cylinder piston rod, mm;represents angle between knuckle arm and connection from knuckle pivot center point to steering cylinder fixed point, (°);represents knuckle rotation angle, (°)。

图2 直线位移传感器安装示意图和数学模型

Fig.2 Displacement sensor fix and mathematical model

通过其几何关系建立的转向油缸行程到转向节转角模型(图2b)。在∆0和∆1中,分别得到

式中1为转向节中心点到转向油缸活塞杆固定点长度,mm;2为转向节中心点到转向油缸固定点的长度,mm;3为车轮对中时的转向油缸长度,mm;为转向油缸活塞杆位移量,mm;为车轮对中时,转向节臂与转向节到转向油缸固定点连线之间的夹角,(°)。

由式(1)~式(4)得到,车轮转角与转向油缸活塞杆位移量的关系式如下

1.3 四连杆式间接转角测量法

四连杆式角度传感器的安装示意图如图3a所示。在实际安装时,采用铅垂线测量、、3点对地高度,通过添加垫片调节固定点与前桥间的高度,确保3个点对地高度一致,以保证四连杆机构在同一平面内运动。

1.转向节臂 2.转向节 3.前桥 4.连杆 5.摆杆

1. Knuckle arm 2. Knuckle 3.Forward axle 4.Connecting rod 5.Pendulum rod

注:4为转向节中心点到四连杆角度传感器在前桥上的固定点长度,mm;5为摆杆长度,mm;6为连杆长度,mm;7为转向节中心点到连杆在转向节臂上固定点的长度,mm;8为车轮对中时,转向节中心点到连杆与摆杆连接点长度,mm;9为车轮转动后,转向节中心点到连杆与摆杆连接点长度,mm;0为车轮对中时,摆杆与前桥夹角,(°);1为车轮转动后,摆杆与前桥夹角,(°);为车轮对中时,转向节臂与前桥夹角,(°);为车轮转动后转向节臂与前桥夹角,(°)。

Note:4represents length of fixed point of knuckle center point to four-bar angle sensor on front axle, mm;5represents Pendulum rod length,mm;6represents connecting rod length, mm;7represents length of knuckle center point to fixed point of bar on knuckle arm, mm;8represents length of knuckle center point to connecting point of bar and swing bar when wheel is centered, mm;9represents length from center point of steering knuckle to connecting point of bar and swing bar when wheel is centered, mm;0represents angle between connecting rod and pendulum rod when wheel is centered, (°);1represents angle between connecting rod and pendulum rod when wheel turned, (°);represents angle between knuckle arm and forward axle when wheel is centered, (°);represents angle between knuckle arm and forward axle when wheel is turned, (°).

图3 四连杆式角度传感器安装示意图和数学模型

Fig.3 Four-bar angle sensor fix and mathematical model

建立如图3b所示的四连杆式转角测量模型。在∆0和∆00中,得到

在∆1和∆11中,得到

如图3b所示,则

式中为四连杆式角度传感器测量值变化量,4为转向节中心点到四连杆角度传感器在前桥上的固定点长度,mm;5为摆杆长度,mm;6为连杆长度,mm;7为转向节中心点到连杆在转向节臂上固定点的长度,mm;8为车轮对中时,转向节中心点到连杆与摆杆连接点长度,mm;9为车轮转动后,转向节中心点到连杆与摆杆连接点长度,mm;0为车轮对中时,摆杆与前桥夹角,(°);1为车轮转动后,摆杆与前桥夹角,(°);为车轮对中时,转向节臂与前桥夹角,(°);为车轮转动后转向节臂与前桥夹角,(°)。

由式(1)、式(2)、式(6)、式(7)、式(9)、式(10)、式(11)得

2 转角测量对比试验

2.1 构建试验平台

为检验和对比位移式间接转角测量法、四连杆式间接转角测量法和直接转角测量法对导向轮转角测量精度的影响,构建试验测试平台。试验平台包括:雷沃M800型拖拉机;北京农业智能装备技术研究中心的AMG-1102型自动导航系统,直线作业横向偏差小于2.5 cm;米朗公司的KPC-250型直线位移传感器,量程为0~250 mm,线性精度±0.05%FS;四连杆式角度传感器为通磁伟业公司的WYT-AT-3型霍尔角度传感器,摆杆长度为145 mm,连杆长度为234 mm,量程为0~90°,线性度1.0%FS;便携式计算机。其中,AMG-1102型自动导航系统采用角度传感器直接测量法,使用通磁伟业公司的WYT-AT-3型霍尔角度传感器。霍尔角度传感器与转向节同轴安装,四连杆式角度传感器固定在前桥上,连杆与转向节臂连接,直线位移传感器与转向油缸并列安装。图4为传感器的安装位置。

2.2 2种间接转角测量法的传感器标定

2种间接转角测量法是通过建立测量模型,将测量值转换为目标值,转换关系式复杂,计算量大,影响转向控制器的控制性能,因此采用最小二乘法线性拟合测量模型,便于转向控制器完成传感器测量值到转角值的转换处理。

2.2.1 直线位移传感器的标定

直线位移传感器安装完成后,测量参数1为142 mm,2为561 mm,3为543 mm,雷沃M800型拖拉机的转向节内倾角=9°,转向节后倾角=1°,对式(5)中位移量与车轮转角的变化关系进行最小二乘法线性拟合。拟合方程为

拖拉机的工作环境使得拖拉机的振动较大,在实际的控制中,振动对AD采样易造成振动干扰。本文选择递推平均滤波,该滤波算法对周期性干扰有良好的抑制作用,适用于振荡系统[28-30],滤波后信号平滑度高。

2.2.2 四连杆式角度传感器标定

四连杆式角度传感器安装后,测量参数4为210 mm,5为145 mm,6为234 mm,7为149 mm,8为286 mm,对式(12)中与转角的变化关系进行最小二乘法线性拟合。拟合方程为

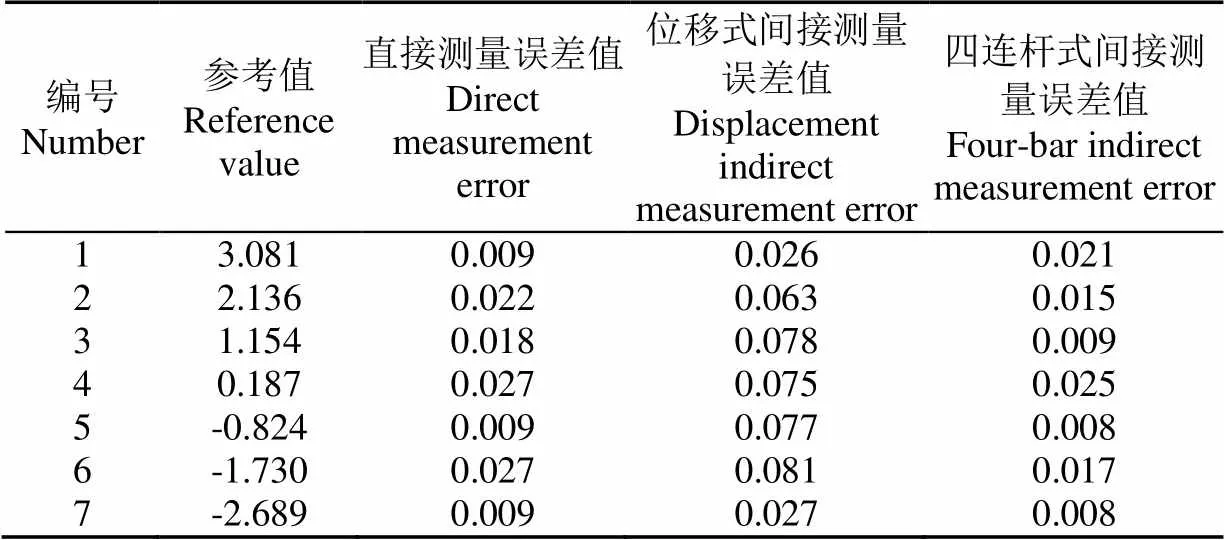

2.3 转角静态测量对比

为了分析直接测量法与2种间接测量法对角度测量值的差异性,设计了转角静态测量试验。试验在平整路面上进行,转动方向盘到不同位置,采用直接测量法、位移式间接测量法和四连杆式间接测量法3种方法分别测量当前转角值,由于车轮转角真值不能直接测量,故以直接测量法20次测量值的平均值为对比参考值,对比3种测量方法的测量结果。考虑到拖拉机自动导航直线行驶时,角度主要在车轮对中位置附近变化,表1中列举了直接测量法测量值、四连杆式间接测量法测量值和位移式间接测量法测量值的部分数据。

表1 转角值测量结果

注:对直接测量法测量20次的结果取平均值,作为参考值。

Note: Results of direct measurement method 20 times average, as a reference value.

由表1可知,3种测量方法测量的角度值最大误差为0.081°,平均误差分别为0.017°、0.014°和0.061°,小于传感器的测量精度0.088°,3种测量方法测量的测量精度一致。

在二轮车运动学模型中[1-2],车轮转角为虚拟中位轮与车身轴线的夹角,这是不可直接测量的,虽然可以通过阿克曼转角模型转换为测量左右车轮的转角,但阿克曼转角模型是建立在理想条件下,有一定的误差[25-26],中国科学院沈阳自动化研究所采用SPZJ-1型汽车转向角检测仪(分辨率0.1°)进行转角测量获得车轮转角值,但是测量精度不高[27]。本研究下一步拟借鉴北京理工大学在汽车领域转角测量方法,通过计算拖拉机运动轨迹切向矢量的方向变化率,结合转向轮侧偏刚度,推算出转向轮转角值[31]。

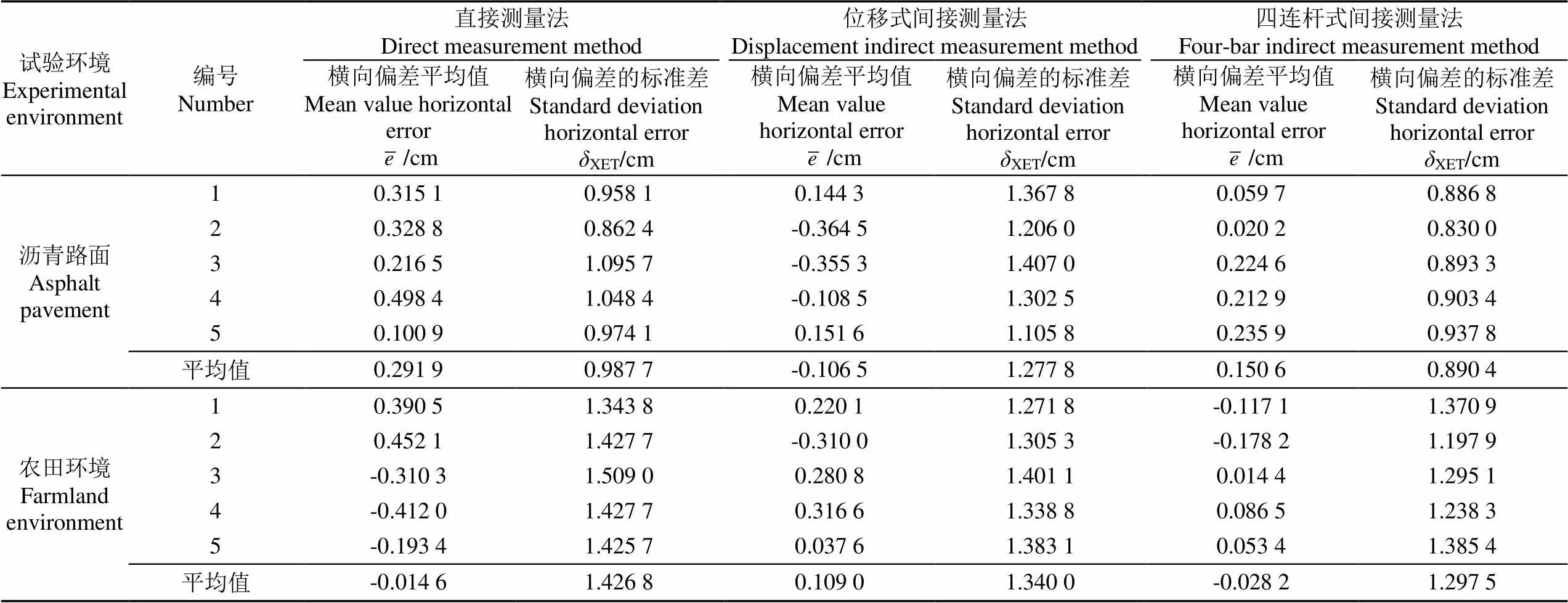

3 导航效果对比试验

试验在北京市昌平区小汤山国家精准农业研究示范基地进行,选择了沥青平整路面和农田地块2种地况,其中沥青路面长度约400 m,农田地块南北长度约200 m。分别采用霍尔角度传感器、直线位移传感器和四连杆式角度传感器作为测量单元,在2种地况下检验自动导航系统的导航精度。在沥青路面上测试时,拖拉机不挂接农具;在田间测试时,拖拉机悬挂农具;车速均保持在4.2 km/h左右。通过导航控制终端实时记录拖拉机自动导航模式下直线追踪导航的横向偏差,以便于分析2种测量方法下的导航精度。

3.1 试验数据处理方法

试验中通过导航终端实时记录拖拉机横向偏差,对横向偏差的平均值(单次试验全部数据取均值)和标准差进行统计分析,作为评价指标。其中平均值反映了自动导航精度的效果,而标准差反映了自动导航时的稳定性[4,32-33],计算式如式(15)与式(16),表2为沥青路面上与农田环境下自动导航横向偏差的统计分析结果。

式中e为时刻的横向偏差,cm;为横向偏差平均值,cm;XET为横向偏差的标准差,表示自动导航的稳定性,cm。

3.2 导航效果对比分析

3.2.1 导航精度对比

沥青路面上,位移式间接转角测量法的导航精度最高,横向偏差均值为0.106 5 cm,小于四连杆式间接测量法的0.150 6 cm和直接测量法的0.291 9 cm;在农田环境下,直接测量法的导航精度最高为0.014 6 cm,小于四连杆式间接测量法的0.028 2 cm和位移式间接转角测量法的0.109 0 cm。

通过沥青路面与农田环境2种地况试验测试,沥青路面上和农田环境下,四连杆式间接测量法、位移式间接测量法和直接测量法的横向偏差平均值的最大值分别为0.235 9、0.364 5、0.498 4 cm,试验表明3种测量方法的导航精度一致。

3.2.2 导航稳定性对比

沥青路面上,四连杆式间接转角测量法的导航稳定性最高,为0.890 4 cm,小于直接测量法的0.987 7 cm和位移式间接转角测量法的1.277 8 cm;在农田环境下,四连杆式间接转角测量法的导航稳定性最高,为1.297 5 cm,小于直接测量法的1.426 8 cm和位移式间接转角测量法的1.340 0 cm。

综上所述,四连杆式间接转角测量法的导航效果是最好的,虽然位移式间接转角测量法的导航精度在沥青路面上是最高的,但传感器内部电刷与阻轨长时间在小范围内摩擦,使得直线位移传感器线性度变差。在农田环境下使用大约50 h后,导航系统的横向偏差均值为0.456 1 cm,标准差为2.683 4 cm,导航精度下降显著。

表2 沥青路面与农田环境横向偏差统计分析表

4 结 论

1)在不考虑车轮变形、机械结构精度等因素下,建立了位移式间接转角测量模型与四连杆式间接转角测量模型,并进行转角测量对比试验。四连杆式间接测量法、位移式间接测量法和直接测量法测量的角度值最大误差为0.081°,平均误差分别为0.061°、0.014°和0.017°,小于传感器的测量精度0.088°,3种测量方法测量的测量精度一致。

2)通过沥青路面与农田环境2种地况试验测试,沥青路面上和农田环境下,四连杆式间接测量法、位移式间接测量法和直接测量法的横向偏差平均值的最大值分别为0.235 9、0.364 5、0.498 4 cm,试验表明3种测量方法的导航精度一致。

3)相对于位移式间接转角测量法和直接测量法,在沥青路面上和农田环境下,四连杆式间接测量法导航精度标准差最小,分别为0.890 4和1.297 5 cm。试验表明,在导航精度一致的情况下,四连杆式角度传感器有最小的导航精度标准差,并且安装方便,易于防护,可以代替直接转角测量法,应用于工程中。

[1] 胡静涛,高雷,白晓平,等. 农业机械自动导航技术研究进展[J]. 农业工程学报,2015,31(10):1-10.

Hu Jingtao, Gao Lei, Bai Xiaoping, et al. Review of research on automatic guidance of agricultural vehicles[J]. Transactionsof the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(10): 1-10. (in Chinese with English abstract)

[2] 姬长英,周俊. 农业机械导航技术发展分析[J].农业机械学报,2014,45(9):44-54.

Ji Changying, Zhou Jun. Current situation of navigation technologies for agricultural machinery[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(9): 44-54. (in Chinese with English abstract)

[3] 杨柳,罗婷婷,程新荣,等. 基于Raspberry Pi 的拖拉机通用自动驾驶系统[J]. 农业工程学报,2015,31(21):109-115.

Yang Liu, Luo Tingting, Cheng Xinrong, et al. Universal autopilot system of tractor based on Raspberry Pi[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(21): 109-115. (in Chinese with English abstract)

[4] 籍颖,张漫,刘刚,等. 农业机械导航系统综合评价方法[J].农业机械学报,2010,41(12):160—164.

Ji Ying, Zhang man, Liu Gang, et al. Synthetically evaluation of agriculture machine navigation system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 160-164. (in Chinese with English abstract)

[5] Xiang Y, Noguchi N. Development and evaluation of a general-purpose electric off-road robot based on agricultural navigation.[J]. International Journal of Agricultural & Biological Engineering, 2014, 7(5): 14-21.

[6] Barbosa R S. New method for railway track quality identification through the safety dynamic performance of instrumented railway vehicle[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2016, 38(8): 2265-2275.

[7] Kraus T. High-speed adaptive nonlinear predictive control for autonomous tractor navigation[C]//Bio-Robotics. 2013: 135-140.

[8] 赵建东. 基于东方红SG-250拖拉机电控液压转向系统研究[D]. 南京:南京农业大学,2012.

Zhao Jiandong. Research of electronic Hydraulic Steering System Based on the Dong Fang-Hong SG-250 Tractor[D]. Nanjing: Nanjing Agricultural University, 2012. (in Chinese with English abstract)

[9] Lee S Y, Yang Haiwon. Navigation of automated guided vehicles using magnet spot guidance method[J]. Robotics and Computer-Integrated Manufacturing, 2012, 28: 425—436.

[10] Maximov V N, Chernomorsky A I. Distributed navigation system for uniaxial wheeled modules[J]. Journal of Computer and System Sciences International, 2016, 55(5): 807—820.

[11] 罗锡文,张智刚,赵祚喜,等. 东方红X-804拖拉机的DGPS自动导航控制系统[J]. 农业工程学报,2009,25(11):139-145.

Luo Xiwen, Zhang Zhigang, Zhao Zuoxi, et al. Design of DGPS navigation control system for Dongfanghong X-804 tractor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(11): 139-145. (in Chinese with English abstract)

[12] Hu J T, Li T C. Cascaded navigation control for agricultural vehicles tracking straight paths[J]. International Journal of Agricultural & Biological Engineering, 2014, 7(1): 36-44.

[13] Thanpattranon P, Ahamed T, Takigawa T. Navigation of autonomous tractor for orchards and plantations using a laser range finder: Automatic control of trailer position with tractor[J]. Biosystems Engineering, 2016, 147: 90-103.

[14] 冯朝印,刘亚楠. 拖拉机转向角检测系统的研究[J]. 农机化研究,2013,12(12):207-209.

Feng Chaoyin, Liu Ya’nan. Vehicles ceflection angle examination system’s research[J]. Journal of Agricultural Mechanization Research, 2013, 12(12): 207-209. (in Chinese with English abstract)

[15] 刘金波,迟德霞,金宏亮. 国内的农用车辆自动转向系统研究进展[J]. 农业科技与装备,2011(4):67-72.

Liu Jinbo, Chi Dexia, Jin Hongliang. Research progress on automatic steering system in domestic farm vehicles[J]. Agricultural Science & Technology and Equipment, 2011(4): 67-72. (in Chinese with English abstract)

[16] 陈文良,谢斌,宋正河,等. 拖拉机电控液压动力转向系统的研究[J]. 农业工程学报,2006,22(10):122-125.

Chen Wenliang, Xie Bin, Song Zhenghe, et al. Electro-hydraulic power steering system for tractors[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(10): 122-125. (in Chinese with English abstract)

[17] 谢明,马蓉,任玲,等.拖拉机自动转向系统设计及仿真[J].农机化研究,2015(11):108-112.

Xie Ming, Ma Rong, Ren Ling, et al. Design and simulation on tractor automatic steering system[J]. Journal of Agricultural Mechanization Research, 2015(11): 108-112. (in Chinese with English abstract)

[18] 黎永键,赵祚喜,黄培奎,等.东方红拖拉机自动转向控制器设计及试验[J]. 农业工程学报,2015,31(增刊2):93-99.

Li Yongjian, Zhao Zuoxi, Huang Peikui, et al. Design and experiment of automatic steering control system based on dongfanghong tractor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(Supp.2): 93-99. (in Chinese with English abstract)

[19] 吴晓鹏,赵祚喜,张智刚,等. 东方红拖拉机自动转向控制系统设计[J]. 农业机械学报,2009,40(增刊):1-5.

Wu Xiaopeng, Zhao Zuoxi, Zhang Zhigang, et al. Development of automatic steering control system based on Dongfanghong tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(Supp.): 1-5. (in Chinese with English abstract)

[20] 尤文宽. 拖拉机播种作业自动转向控制系统的设计与研究[D]. 石河子:石河子大学,2014.

You Wenkuan. Design and Research on Automatic Steering Control System of Tractor seeding operation[D]. Shihezi: Shihezi University, 2014. (in Chinese with English abstract)

[21] 刘沛,陈军,张明颖. 基于激光导航的果园拖拉机自动控制系统[J]. 农业工程学报,2011,27(3):196-199.

Liu Pei, Chen Jun, Zhang Mingying. Automatic control system of orchard tractor based on laser navigation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(3): 196-199. (in Chinese with English abstract)

[22] 任文涛,迟德霞,刘金波,等. 遥控插秧机自动转向系统设计与试验[J]. 农业机械学报,2012,43(1):175-179.

Ren Wentao, Chi Dexia, Liu Jinbo, et al. Design and test on remote rice transplanter automatic steering system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(1): 175-179. (in Chinese with English abstract)

[23] 刘军,袁俊,蔡骏宇,等. 基于GPS/INS 和线控转向的农业机械自动驾驶系统[J]. 农业工程学报,2016,32(1):46-53.

Liu Jun, Yuan Jun, Cai Junyu, et al. Autopilot system of agricultural vehicles based on GPS/INS and steer-by-wire[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 46-53. (in Chinese with English abstract)

[24] 张义华,高公如,韩斌,等. 装载机线控转向角度测量控制研究[J]. 设计与研究,2013(4):19-21.

Zhang Yihua, Gao Gongru, Han Bin, et al. Loaders steer-by-wire angle measurement control[J]. Journal of Design And Research, 2013(4): 19-21. (in Chinese with English abstract)

[25] 王鹤,胡静涛,高雷. 农业机械自动导航车轮转角测量误差补偿模型[J]. 农业机械学报,2014,45(8):33-37.

Wang He, Hu Jingtao, Gao Lei. Compensation model for measurement error of wheel truning angle in agricultural vehicle guidance[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 33-37. (in Chinese with English abstract)

[26] 王霄锋,胡涛,金晓辉,等. 汽车内、外前轮转角关系的实验研究[J]. 拖拉机与农用运输车,2010,37(4):13-15.

Wang Xiaofeng, Hu Tao, Jin Xiaohui, et al. Experimental study on relationship between inside and outside steered wheels of motor vehicle[J]. Tractor & Farm Transporter, 2010, 37(4): 13-15. (in Chinese with English abstract)

[27] 郭孔辉,李宁,景立新. 基于转向试验的车辆主销定位参数完整解算[J]. 农业机械学报,2011,42(10):1-5.

Guo Konghui, Li Ning, Jing Lixin. Calculation of vehicle kingpin positional parameters based on steering test[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(10): 1-5. (in Chinese with English abstract)

[28] 杨德,邓国强,畅福善. 整车式不停车称重系统设计[J].控制工程,2015,22(6):1114-1117.

Yang De, Deng Guoqiang, Chang Fushan. Design of non-stop and whole vehicle weighing system[J]. Control Engineering of China, 2015, 22(6): 1114-1117. (in Chinese with English abstract)

[29] 文常保,高丽红,方吉善,等. 基于改进型限幅平均滤波法的高精度称重系统研究[J]. 传感技术学报,2014,27(5):649-653.

Wen Changbao, Gao Lihong, Fang Jishan,et al. The high-precision weighing system based on the improved amplitude-limiting and average filtering algorithm[J]. Chinese Journal of Sensors and Actuators, 2014, 27(5): 649-653. (in Chinese with English abstract)

[30] 熊连松,卓放,刘小康. 增强型滑动平均滤波算法及其在畸变电网相位同步控制中的应用[J]. 电工技术学报,2015,30(21):13-23.

Xiong Liansong, Zhuo Fang, Liu Xiaokang. Enhanced moving average filter and its applications in phase locking control of distorted power system[J]. Transactions of China Electrotechnical Society, 2015, 30(21): 13-23. (in Chinese

with English abstract)

[31] 刘启佳. 四轮转向汽车侧向动力学最优控制和内外环联合控制研究[D]. 北京:北京理工大学,2014.

Liu Qijia. The Lateral Dynamic Optimal Control of Four Wheel Steering Vehicle and the Research of Inner Loop Controller and Outer Loop Controller Cooperate Simulation[D]. Beijing: Beijing Institute of Technology, 2014. (in Chinese with English abstract)

[32] 吉辉利,王熙. 拖拉机卫星导航精度评估方法研究[J]. 农机化研究,2016(11):242-262.

Ji Huili, Wang Xi. The research of agricultural machinery is about satellite navigation accuracy of the evaluation method[J]. Journal of Agricultural Mechanization Research, 2016(11): 242-262. (in Chinese with English abstract)

[33] 朱永兴,冯来平,贾小林,等. 北斗区域系统的PPP精度分析[J]. 测绘学报,2015,44(4):377-383.

Zhu Yongxing, Feng Laiping, Jia Xiaolin, et al. The PPP precision analysis based on bds regional navigation system[J]. Acta Geodaetica et Cartographica Sinica, 2015, 44(4): 377-383. (in Chinese with English abstract)

Comparative test between displacement and four-bar indirect measurement methods for tractor guide wheel angle

Hu Shupeng1,2, Shang Yehua2,3, Liu Hui1, Li You2,3, Zhao Chunjiang2,3, Fu Weiqiang2,3※

(1.100048; 2.100097,; 3.100097,)

Wheel swivel angle is regarded as a critical parameter in agriculture automatic navigation system, and it can always be measured by using angle sensor. In engineering practice, angle sensor is difficult to fix, and the shaft is easily broken. In order to solve the problem, displacement indirect measurement method and four-bar indirect measurement method are proposed in this paper. Wheel rotation depends on steering cylinder piston movement, and the movement of steering cylinder piston causes the movement of steering trapezoidal mechanism. Therefore it is available to apply displacement sensor in measuring the position of the steering cylinder piston rod, and the displacement sensor is parallel fixed with the steering cylinder. Referring to the motion of steering trapezoidal mechanism, it is proposed to use the front axle, knuckle arm, connecting rod and pendulum rod to form a four-bar linkage. According to the fixed location of the displacement sensor and four-bar angle sensor, it is available to establish measurement models for those 2 indirect measurement methods, and calibrate the relation between sensor measurement and wheel swivel angle, but those 3 measurement methods are incapable to measure the real wheel swivel angle. In the 2 kinematic models of wheel vehicle, wheel swivel angle is the angle between wheel axis and vehicle body axis, and thus Ackerman transformation must be used for converting the test angle into wheel swivel angle. However, different vehicles are different in the transformation of Ackerman, and the ideal Ackerman transformation cannot be used. In fact, the rotation angles of left and right wheels have little bias with the wheel swivel angle when the wheel swivel angle is being in a small range in the middle of the pair. Therefore it is supposed that the measurement angle is the wheel swivel angle. Through automatic navigation precision comparison experiment, the advantages and disadvantages of different measurement methods are compared. The experiment is performed on basis of the LOVOL tractor M800, in which the self developed automatic navigation system was used, and an experiment platform was built. The experiment is completed on the asphalt pavement and the field, and the platform can be utilized to compare the accuracy of 3 measurement methods of wheel swivel angle and compare the accuracy of navigation through statistical analysis. The result shows that the four-bar angle sensor can provide the highest angle measurement accuracy and navigation accuracy. When the vehicle keeps the speed of about 4.2 km/h, the mean value of lateral deviation is -0.028 2 cm by using the four-bar angle sensor in the field, and the mean value of lateral deviation is -0.014 6 cm by using the hall angle sensor and 0.109 0 cm by using the displacement sensor in the same experiment environment. Therefore the four-bar indirect measurement method offers almost a navigation accuracy equal with the direct angle measurement, but the standard deviation of lateral deviation for automatic navigation of the four-bar indirect measurement method is 1.297 5 cm, which is less than the direct measurement method.But considering the displacement sensor wear, when the sensor has been used for about 50 h in the same environment, the mean value of lateral deviation is -0.456 1 cm. Thus the displacement angle measurement is incapable of replacing the direct angle measurement,while the four-bar angle sensor is capable to replace direct angle measurement method and can be further applied in practice, which is easily fixed and protected.

agricultural machinery; steering; models; automatic navigation; wheel swivel angle measure; displacement; four-bar; navigation accuracy

10.11975/j.issn.1002-6819.2017.04.011

S237; U463.42

A

1002-6819(2017)-04-0076-07

2016-05-20

2016-12-12

国家“863”高技术研究发展计划项目(2013AA102308);国家自然科学基金资助项目(31571564,31571563);北京市科技计划课题(D161100003216003)

胡书鹏,男(汉族),河南信阳人,主要从事拖拉机自动导航技术研究。北京 首都师范大学信息工程学院,100048。 Email:fengshengppp@163.com

付卫强,男(汉族),河北定州人,副研究员,博士生,主要从事农业智能装备与导航技术研究。北京 北京农业信息技术研究中心,100097。Email:fuwq@nercita.org.cn

胡书鹏,尚业华,刘 卉,李 由,赵春江,付卫强. 拖拉机转向轮转角位移式和四连杆式间接测量方法对比试验[J]. 农业工程学报,2017,33(4):76-82. doi:10.11975/j.issn.1002-6819.2017.04.011 http://www.tcsae.org

Hu Shupeng, Shang Yehua, Liu Hui, Li You, Zhao Chunjiang, Fu Weiqiang. Comparative test between displacement and four-bar indirect measurement methods for tractor guide wheel angle[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(4): 76-82. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.04.011 http://www.tcsae.org