Graphene Based Electrochemical Sensor for the Detection of Volatile Organic Compounds

2015-06-02YixinZhangKimKTL

Yixin+Zhang+Kim+KT+Lau

Abstract:Many household consumables contain volatile organic compounds (VOCs) as the active ingredient. Long term exposure to VOCs could cause various health problems, especially to the respiratory system. Graphene has attracted a lot of attention recently for its potential to be used as sensing material for VOCs. In this project we have constructed graphene/PVA composite based gas sensors for VOC detection. It was perceived that the polymer could introduce better selectivity to the sensor. Results suggest that the proposed sensor is highly sensitive to low molecular weight VOCs and that the manner in which the sensor respond to the vapour depends on the polarity or hydrophobicity of the vapour.

Keywords:gas sensor; volatile organic compounds (VOCs); grapheme; electrochemical sensors

Ⅰ.Introduction

1. Background of VOC

Volatile organic compounds (VOCs) are low boiling organic solvents and solids with high vapor pressure at room temperature. They are major component in household consumables such as cleaners, paints, glues, building material etc. (Figure 1) and hence exposure to VOCs is unavoidable. Acute exposure to high concentration and chronic exposure to low concentrations of VOCs pose different health risks. Acute poisoning causes severe headache, vomiting, coughing, irritation and damage to respiratory system and cornea of the eyes. In serious cases, it can result in fatality. Chronic exposure to low concentration of VOCs could cause asthma, skin disease, migraine, drowsiness, general fatigue, and in some cases, cancer.Typical examples of VOCs are ethanol, propanol, formaldehyde and chloroform. Air pollutants in home environment constitute mainly these organic solvents, especially in China, the strong economic drives building industries to flourish; thousands of new estates are built every year with millions of people now living in environment with slow release of toxic VOCs. One commonly encountered is formaldehyde. The elderly and the young are the most affected populations because of their weakened or under developed immune system. To protect such population and the healthy alike, gas sensors that are simple, small, inexpensive and easy to use are in high demand. This project is to explore a new carbon material, graphene, as a potential sensing material in the development of sensor that fits the above criteria.

2. Graphene as a Sensing Material

Graphene is a form of carbon that can be easily synthesized. The physical and chemical properties of this new material are totally different from graphite. All the atoms in graphene are strictly arranged into a two-dimensional (2D) honeycomb lattice, hence graphene is highly flexible and is an excellent conductor. Super electron mobility and transport properties boost graphene as a sensing material. It has very good mechanical strength, very large surface area, and is chemically and physically stable (Figure 2).

3. Principle of Gas Sensing

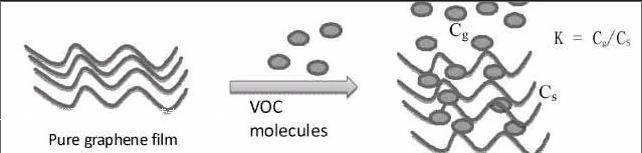

Absorption of VOC molecules causes the graphene film to undergo a volume change to results in a change in resistance (ΔR), where ΔR = Rfinal – Rinitial.

The simplified sensing mechanisms can be illustrated in Figure 3:

When the graphene film is exposed to a gas or vapour, the gas molecule will diffuse into and out of the film, and at equilibrium, the number of gas molecules absorb into the film is equal to the gas molecule leaving the film[14]. The film resistance also changes from an initial value Rinitial to a final value Rfinal which is related to the amount of gas molecules absorbed.

The equilibrium constant K for the gas-solid interactions can be defined as:

K = Cg/Cs

where Cg is the gas concentration in gas phase and CS the gas concentration in the solid film.

Since K is specific to a gas-sorbent combination, the sensitivity and selectivity of a given sorbent material can be established.

4. Objective

Graphene is an excellent absorbent for many vapours, hence a sensor based on graphene alone may offer good sensitivity but the selectivity will generally be poor[15]. It is anticipated that the addition of polymer materials with different chemical functionalities would improve the selectivity performance of graphene based sensor. In this short summer student project, we explore the use of Graphene/PVA composite sensor for measuring VOCs. The aims of this project is to investigate how the Graphene/PVA based sensor would response to VOC standards and to evaluate the optimal ratio of Graphene/PVA to give fast, sensitive, stable and repeatable sensor response.

Ⅱ. Experimental Procedure

1. Sensor Construction

Graphene Oxide/polyvinyl alcohol (GO/PVA) composite film was first formed on the electrode from casting a solution of GO/PVA mixture of a certain ratio on the electrode, followed by drying in the oven. Then excess hydrazine hydrate was added onto the surface of the film for GO reduction. The reaction was allowed to proceed at 90°C for 1 hour to afford a solid thin film of PVA/graphene composite. (Figure 4) The procedure was repeated to form multiple layers of GO/PVA composite film.

2. Sensor Calibration

Test VOC sample 2 mL was put into a 20 mL glass vial with a screw cap. The sensor was fixed on the modified cap and then sealed into the sample vial containing the test VOC sample. Laboratory air was used as the reference and sensor resistances in air and inside the sample vial were recorded in real time by an HP Multimeter using a Microsoft ExcelTM compatible HP software. The list of sample tested includes methanol, ethanol, 1-propanol and isopropanol.

Ⅲ. Results and Discussions

1. Sensor performance

Here we present the performance of an optimized sensor fabricated from 10% (w/w) Graphene Oxide in PVA. The sensor was fabricated with 2 layers of the composite film and had an initial sensor resistance of 88.2 k.

The choice of PVA as the polymer matrix for the fabrication of the gas sensor is to introduce selectivity to organic vapours that are able to form hydrogen bonding with the hydroxyl groups of the polymer. Alcohols therefore would be the expected targets for this investigation. Hence a group of alcohols methanol, ethanol, propanol and isopropanol were used to calibrate the proposed sensor.

In order to meaningfully compare their responses, all sensor response are normalized with the actual vapour concentration in the sample vial, and also with baseline corrected.

The actual vapor concentration for each sample VOC was calculated according to the ideal gas equation: P V = n R T (1) and

Antoine equation: log P = A - B / (t +C) (2)

(where P is vapor pressure, V is volume, n is the number of mole, T is temperature , R is the gas constant; A, B, C are constants).

A typical real time sensor response profile is shown in Figure 5 to demonstrate the sensor behavior on exposure to methanol vapour. On exposure to methanol, the sensor resistance increased rapidly and reached equilibrium in approximately 20 s. A normalized resistance change of ca.19 K?.m3/g was recorded which corresponded to ca. 10% change in resistance. However, a baseline drift was observed due to a ‘memory effect which is quite typical of polymer based sensors.

Shown in Figure 6 are the sensor response profiles of the four alcohol vapours, methanol, ethanol, propanol and isopropanol. Interestingly, very different response characteristics were observed depending on the size and structure of the vapour molecules. Methanol and ethanol caused the sensor resistance to increase as expected, due to the swelling of the sensor film as a result of strong H-bonding interactions between the hydroxyl groups of the vapour molecules and those of the PVA polymer. However, unexpectedly, both propanol and isopropanol caused the sensor resistance to decrease, meaning that electron conduction had been made more efficient with the absorption of the molecules. A speculation is that the hydrophobic interactions between the polymer backbone, the vapor molecules and the graphene create alternative conduction pathways to allow better electron hopping. At present, there is not enough evident to explain the observation, and this will be an interesting subject of future investigation.

2. Repeatability of sensor

This graphene/PVA composite based sensor responded to vapours with good repeatability. Figure 7 shows a typical example of the sensor being repeated exposed to methanol vapour. Although there was obviously a basline drift after each exposure, the actual sensitivity i.e. resistance change (?R) measured were quite consistence, with standard deviation of ca. 5% (n =3). The repeatability of responses for other alcohol vapours were within the same range, indicating that the effect of baseline drift did not have significant effect to the sensitivity of the sensor. Overall, this proposed Graphene/PVA composite based gas sensor gave satisfactory response characteristics. It is believed that further optimisation of sensor fabrication technique and polymer:graphene ratio would improve further the sensor performance. This work to evaluate the feasibility of this composite approach of sensor fabrication has been encouraging, and results suggest that polymers with different chemical signatures could improve the selectivity of the sensor. However, much research effort are needed in the future to fully explore the possibility.

Ⅳ. Conclusion

Wehave successfully constructed graphene/PVA composite based gas sensor for measuring alcohol vapours. The sensor has exhibited good sensitivity, fast response time with also good repeatability. An unexpected behavior towards the two propanols was observed that required further investigation.

Acknowledgement

The authors would like to thank XJTLU SURF programme 2014 for financial support.

Reference:

[1]D. S Hafner, et al. Emission of Volatile Organic Compounds from Silage: Compounds, Sources, and Implications. Atmospheric Environment , 2013 (77): 827–839.

[2]S Cakmak, et al. Residential Exposure to Volatile Organic Compounds and Lung Function: Results from a Population-Based Cross-Sectional Survey. Environmental Pollution, 2014 (194): 145-151.

[3]P. A Jones. Indoor Air Quality and Health. Atmospheric Environment, 1999 (33.28): 4535–4564.

[4]M. J Mendell. Indoor Residential Chemical Emissions as Risk Factors for Respiratory and Allergic Effects in Children:A Review. Indoor Air, 2007: 259-277.

[5]E. M Adler. A Volatile Response to Injury. Science, 2007: 112.

[6]R Dales. Quality of Indoor Residential Air and Health. Canadian Medical Association Journal , 2008: 147-152.

[7]P Wolkoff, et al. Organic Compounds in Office Environments-Sensory Irritation, Odor, Measurements and the Role of Reactive Chemistry. Indoor Air, 2006: 7-19.

[8]Mallya et al. Conducting Polymer–Carbon Black Nanocomposite Sensor for Volatile Organic Compounds and Correlating Sensor Response by Molecular Dynamics. Sensors and Actuators B: Chemical, 2014 (201): 308–320.

[9]C Lee, et al. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science, 2008 (321.5887): 385-388.

[10]A. A Balandin. et al. Superior Thermal Conductivity of Single-Layer Graphene. Nano Letters, 2008 (8.3): 902-907.

[11]A Geim. & K Novoselov. The Rise of Graphene. Nature Materials , 2007 (6.3): 183-191.

[12]K. I. Bolotin, et al. Ultrahigh Electron Mobility in Suspended Graphene. Science, 2008 (146.9-10): 351-355.

[13]S. V. Morozov, et al. Giant Intrinsic Carrier Mobilities in Graphene and Its Bilayer. Physical Review Letters , 2008: 100.

[14]W Zhang. Exploring Graphite Oxide and Its Derivatives as Materials for Building Chemical Sensors. Laboratory of Advanced Materials and Smart Sensors. Suzhou, 2014.

[15]Y Dan, et al. Intrinsic Response of Graphene Vapor Sensors. Philadelphia: National Center of Biotechnology Information, 2009.

[16]C.L. Yaws & H.C. Yang. To Estimate Vapor Pressure Easily. Hydrocarbon Processing, 1989: 65.

(责编 田彩霞)